| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

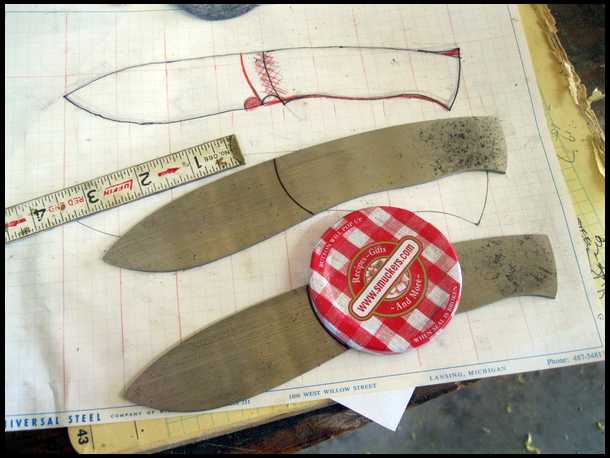

Here is a pair of knives I made for my knapping neighbor and my old boss in Oklahoma. I saved a bunch of ol' stuff from the shop at work. It was for Christmas.

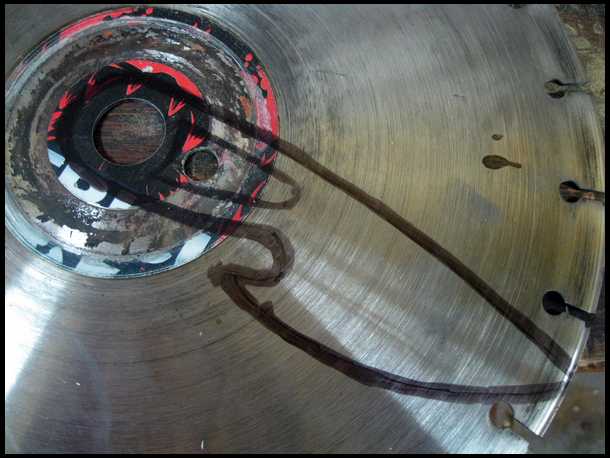

The diamond blade is from the asphalt crews trash. John

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Cut free

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Shape cleaned up

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Layout for handle

|

|

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Full bevel on one and half on other

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Stoner, I had always been under the impression that diamond & carbide blades were not good cutting steel because it was the inserts that done the cutting & not the steel blade. Hopefully that was mis information. How do you judge if they are good knife making steel? Thanks, >>>----> Ken

|

|

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Brass rivet holes

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

The oak is from the boards on the haul truck used for graders, dozers and other heavy equipment. John

|

|

| From: Batman

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

WOW! Gonna look GREAT when FINISHED!

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Never know what is laying around the shop or do a little dumpster diving. Ol' torch tips wood from road work. John

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Ken, the steel that I have been using has been good for holding an edge. Only thing I have found is these blades get HOT!!! So inspect them carefully. See the next three pics. Thanks John

|

|

|

|

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Handles shaped up

|

|

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Finished up and ready to build a sheath.

|

|

|

|

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Done

|

|

| From: Mike E

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Very nice work,,Thanks for sharing.

|

|

| From: Knifeguy

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Very nice!

|

|

| From: carpenter

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Outstanding work!

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Stoner if you can drill without annealing, the steel is not hard enough for good blades. If it gets hot enough to change color when grinding you have altered the temper. Nice looking knives. The sheaths are very nice too. I just hate to see effort wasted if the steel is not good to start with. There would be no point in using good hard cutting steel to weld carbide cutters on but maybe some do. >>>----> Ken

|

|

| From: cobra

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Beautiful!

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Ken , I usually use wood cutting blades and do not let the steel change color. The handles are drilled with a special drill bit. Normal drill bits dull half way thru. Don't know whats right or wrong yet, jus' playin' around.

I hope to learn more soon. There is a local fellow here in Phoenix that is holding blacksmith classes with small groups only to give a little one on one time. I'll keep ya'll posted. Thanks for the input. John

|

|

| From: Gray Goose Shaft

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Wow, from rusty saw blade and rough boards to a really nice pair of knives.

|

|

| From: BRIBOWl

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Very nice wish I had your talent.

|

|

| From: BRIBOWl

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Very nice wish I had your talent.

|

|

| From: Randog

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Stoner, you do some very nice work. No shortage of talent on the Wall.

|

|

|

|

| From: Don T. Lewis

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Beautiful knives John. Outstanding!

|

|

| From: Don T. Lewis

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Beautiful knives John. Outstanding!

|

|

| From: Frisky

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

I like them!

Joe

|

|

| From: Corax_latrans

|

|

|

|

|

|

|

| Date: 09-Dec-22 |

|

Dang!

Neighbor across the street is a mason…. I’m gonna to ask him to save me some blades!!

That and (hot tip!!) those 1 cubic yard bags that they use to deliver gravel and what- not?? BEST THING EVER for hauling yard waste….

|

|

|

|

| From: Supernaut

|

|

|

|

|

|

|

| Date: 10-Dec-22 |

|

Beautiful knives John and thanks for the pics and build along!

|

|

| From: selstickbow

|

|

|

|

|

|

|

| Date: 10-Dec-22 |

|

JOHN, wow, nice knives & good on you making them for a friend. Steve Long

|

|

|

|

|

|

|

|

| From: Cedarsavage

|

|

|

|

|

|

|

| Date: 10-Dec-22 |

|

Pretty slick I like the handles

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 10-Dec-22 |

|

Pretty slick.

|

|

| From: Buzz

|

|

|

|

|

|

|

| Date: 10-Dec-22 |

|

Great job.

|

|

| From: ephphatha

|

|

|

|

|

|

|

| Date: 10-Dec-22 |

|

Those handles are cool.

|

|

| From: treehermit

|

|

|

|

|

|

|

| Date: 11-Dec-22 |

|

Those are nice. What did you use to create that bevel?

|

|

| From: buckeye

|

|

|

|

|

|

|

| Date: 11-Dec-22 |

|

I acquired a concrete blade very similar to yours and it didn't have enough carbon to take a heat treat. Whenever I have mystery steel, I will cut a piece about knife sized and stick it in the forge until a magnet no longer sticks to it. Dunk it in oil, then clamp it in a vice and smack it with a hammer. If it shatters or breaks clean, you have knife worthy steel, if it just bends , take it to the scrap yard or use it for something else. Your talent and time should be utilized on good materials. Those look really good by the way.

|

|

| From: B.T.

|

|

|

|

|

|

|

| Date: 11-Dec-22 |

|

I'm impressed.

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 11-Dec-22 |

|

Dan, thank for the tip on the heat and magnet. Will definitely try. I am still very much a novice in this. As I said I hope here in the near future to take a blacksmith class in Pheonix.

Thomas, I use a belt sander to do the bevels. Have done some freehand and with a home made jig.

|

|

| From: treehermit

|

|

|

|

|

|

|

| Date: 11-Dec-22 |

|

Thanks. They are nice and the leatherwork too.

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 11-Dec-22 |

|

You will learn a lot from the blacksmith class. Basically if you start with hard metal you need to anneal it to work. If you don't you have to be very careful not to get it hot enough to change the color or you destroy the temper. When the edge gets thin that is where it will overheat the quickest & destroy the cutting edge. Cutting steel blades are usually too hard & can be drawn back a little in the oven or toaster oven 300 to 400 degrees. If it is soft to start with work it until near finished don't get the edge thinner than 1/32 or it will warp. heat/harden it until non magnetic & quench. It will be super hard. Then finish the edge & polish it & draw it back to desired hardness in the oven. Heat & quench/cool quickly to harden. Heat and slow cool to aneal. Low heat 3 to 4 hundred to draw. Carbon steel only Stainless is entirely different. P.S. Didn't mean to be negative in above posts just hate to see anyone waste time & talent if they don't have decent material to start with. >>>>-----> Ken

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 11-Dec-22 |

|

Thanks Ken, When I fist started carving decoys we would throw the carving on the table in front of everyone. Then they would proceed to tear it apart. But Constructively. I try not to wear my feelings on my sleeve. I prefer to take it and build it better next time. John

|

|

| From: Bigdog 21

|

|

|

|

|

|

|

| Date: 11-Dec-22 |

|

Nice I like it.

|

|

| From: Zbone

|

|

|

|

|

|

|

| Date: 12-Dec-22 |

|

Great thread, THANKS for sharing... Awesome work...

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|