| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

It’s a pretty nice day here on Beaver Island, 39 degrees. I moved here about a year and a half ago and due to the expense of getting our stuff here I was unable to bring any bow wood with me so I went out today to get a sapling or 2 and see if I could dry one fairly quickly. I’ll most likely cut some bigger stuff and split into staves later in the spring. HHB seems to be the best wood on the island and it is very abundant. Lots of straight looking stuff but most have twist in them. I found this little snaky sapling with no twist and couldn’t resist cutting it. I peeled it and shellacked it because I didn’t know how badly it would check if I didn’t. It’s about 1 1/2” wide by 62” long. Hoping I can get a bendy out of it around 40-45#.

|

|

|

|

| From: Deno

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

|

|

| From: Deno

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

Lookin' good

|

|

| From: 2FLETCH

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

I cut several HHB trees here in NC growing along the Haw River. The wood made a bow with good cast, but the wood had a tendency to break easy. The trees that I cut were from the same area, so it might be different from another area. Good luck.

|

|

| From: Chas

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

Steve, what tool did you use to peel the bark? thanks

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

Deno thanks for fixing that! Chas, I have an old meat cleaver I use like a draw knife and a cabinet scraper to get the cambium and clean it up

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

Looks nice Steve. I can’t tell from my phone . Did you reduce belly side at all? HHB around here likes to check. If you can reduce the belly side to closer to bow dimensions it really helps to dry belly side without drying checks . Definitely seal the back and ends. I think HHB checks worse when harvested in summer or spring. I’ve had some I peeled, sealed with a couple coats but didn’t split into staves . It’s split by itself before I could get to them.

It makes a nice bow. I probably made 30 before I came across a piece of Osage. It’s not Osage though.

Bjrogg

|

|

| From: Altitude Sickness

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

Looks good. I think Brian BJROGG has built HHB bows hopefully he will jump in.

I like the cabinet

|

|

| From: wooddamon1

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

I've got one blanked out in the shop from last spring. The smaller diameter stuff I cut and de-barked is sealed on the ends and it checked badly along the length. The one that's close to bow dimensions is fine with the ends and back sealed.

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

Thanks Brian. I’ll probably get to reducing it possibly tomorrow. I had an apple stave I reduced to floor tiller last week. I sealed the back and ends and the belly checked beyond belief overnight. Didn’t want that happening again

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

Treat it like hickory.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 16-Feb-22 |

|

It is a very good bow wood. Here is how I make sapling bows.

http://traditionalarchery101.com/saplingbow.html

Jawge

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

If a reduced and sealed stave checks badly overnight, I'd first study the conditions it was stored in for being too warm, dry, air movement, etc.

HHB here seems fairly stable. The last time I brought home a load of HHB, several good sized logs, it was Sep/Oct I think, so the sap was mostly down, and I immediately split them and took them into a part of the garage that was cool, dark, no air movement, no heat or a/c. But within a few days I started removing bark, sealed their backs with shellac, reduced them to 2" wide, 3/4" thick, steaming and reflexing some of them, and then just left them in my shop to dry. The shop IS climate controlled, but not a single drying check happened in any one of them.

That said, sapling staves can be harder to dry without issues than staves from bigger trees.

|

|

| From: Ironfist

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

I have built quite a few bows using HHB. its the best wood we have here in Atlantic Canada. I have'nt cut any but rather acquired staves and all have had the bark left on to season. Removing the bark when dry is something I like doing. I know that bugs can get under the bark but thus far I have not seen that happen with HHB unlike Ash which the bugs love. Good luck with your HHB .

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

I agree with Jeff. I store in a shop that has in floor heat. The temp is about 59 or 60 degrees and it isn’t overly dry like a wood stove heat.

I’ve had Osage check on me overnight when I chased a ring on what I thought was dry stave. I always seal back now right away even if I get pulled away before I finish chasing my ring.

HHB makes a good wood. It isn’t as forgiving as Osage and it doesn’t take heat corrections as good as Osage, but it still makes a fine bow.

I find it likes a good deep heat treatment. You can feel the difference in the wood with the scrapper after heat treatments. And it smells really good.

Ahh the smell of heat treated HHB in the morning

Bjrogg

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

Thanks for the tips gentlemen. I have baseboard electric heat in the shop. It is mid 50s with 50% humidity. Just to make sure I’m clear I should reduce the stave but leave the belly unsealed?

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

Yes reduce the belly but leave it unsealed. Seal everything else. We want the stave to dry from belly side to avoid drying checks. As the wood dries it shrinks. The closer to bow dimensions the more evenly the drying and shrinking. The more we can The checks aren’t the death of a stave, but they don’t look good and if they run off edge they could be trouble.

Your stave will dry faster and with less chance of checking when roughed out close to bow dimensions.

Bjrogg

PS the first couple weeks are worst for checking. Putting stave in a cool place for a week helps to. Some woods are very susceptible to checking and have to be dried very slowly yet not allowed to get a fungus. Some are pretty resistant to checking and I’ve been told don’t even require sealing back

|

|

| From: Runner

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

You don't need to seal the belly. I used to quick dry HHB without it checking by roughing the stave out with the bark on and then removing the bark gradually over about a ten day period. By the time I got to using a spoon to plough off the inner bark the stave would be safe from checking on the back.

|

|

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

Just for clarification, the sides don't need sealed either, just the back and ends.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

Hophornbeam can make a good solid reliable efficient bow. It's my favorite white wood. Diffuse porous. Likes to grow twisted. Don't cut those ones. Seek perfectly straight growing trees, enough exist, it's easy to see by the bark. Small growth rings and smallish trees, like yew, throw em on your shoulder and walk out, splits easy, dries easy, cuts easy, smells good, tillers easy, designs, feels, and shoots kinda like osage. I like it.

|

|

| From: Runner

|

|

|

|

|

|

|

| Date: 17-Feb-22 |

|

We get some pretty large ones here and as far as ease of splitting....sometimes yes, often not.

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

Same here runner. My HHB is usually really difficult to split. I usually use Marc’s cerf and split method.

It does like to grow twisted though and you can usually tell from the bark if it’s twisted or straight.

I only harvest ones that the bark isn’t twisted on. I’ve had people give me beautiful logs. Nice and straight, but I could se the twisted bark. Some twisted over 180 degrees in 7 feet

Bjrogg

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

Yep, it sure likes to grow twisted most times, but I only cut em if the bark runs perfectly straight. That last batch I cut though was on my buddy's property and for some reason there were way less twisted ones at his place. Loggers were soon to move in, so I cut all the nice ones I could find.

HHB/ironwood makes good french rolling pins too :^)

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

...beinz-at it's hard, tough, and diffuse porous, it polishes up on the lathe like glass. The girls at my wife's bakery love them :)

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

I reduced it to about 3/4 so far. Had a couple of checks on the back. I flooded them with c/a glue.

|

|

|

|

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

Put a coat of Elmers over the shellac on the back. Should I give it a couple days or so then reduce further? 62” long 1 1/2 to mid limb taper to 1” tips 3/4” thick except the handle area.

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

Put a coat of Elmers over the shellac on the back. Should I give it a couple days or so then reduce further? 62” long 1 1/2 to mid limb taper to 1” tips 3/4” thick except the handle area.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

That should be reduced far enough.

The relative humidity is still a concern though. Did those checks just show up today? Do you have anywhere to put it where the r.h. is higher than 50%?

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

Just noticed them Jeff. I sealed the whole bow and I noticed the checks are both by small knots. Maybe a route for the moisture? I could sit it outside the shop in the garage. Single digits here if that matters

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

The belly and sides are worked and left unsealed

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 18-Feb-22 |

|

I'd let it go like that and see what happens. Maybe it did it because of the knots and because the whole stave was sealed? Not sure.

|

|

| From: Stickbow Felty

|

|

|

|

|

|

|

| Date: 19-Feb-22 |

|

Picked up some Michigan hornbeam today.It's been drying for about a year.

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 19-Feb-22 |

|

That’s some nice HHB.

Bjrogg

|

|

|

|

| From: Stickbow Felty

|

|

|

|

|

|

|

| Date: 19-Feb-22 |

|

Anyone know what the moisture content should be on the hornbeam?

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 19-Feb-22 |

|

When I tiller a knotted area I leave that area just a little stiffer than the rest of the limb. I think you should too, Steve, especially since there is a check there. Checks with the grain are not a problem but checks with knots may be. Jawge

|

|

| From: Bassmaster

|

|

|

|

|

|

|

| Date: 19-Feb-22 |

|

The other Horn Beam (Blue Beach) has a tendency to check at the knots also, but you can bend recurves with dry heat with it with no problems. Strange but true at least in my experience with it. No experience with the Horn beam you are showing.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

Bassmaster, I think he meant Hophornbeam. At least that's what it looks like from here.

Guys, just to eliminate confusion, try to keep em straight. Hophornbeam (Ostrya virginiana) and Hornbeam (Carpinus caroliniana) are two different trees.

Stickbow Felty, even though it's been 'drying' for a year, it's moisture content depends on the environment it was kept in. You can start to reduce them some now, bring them to 1 3/4" or 2" wide end to end, then remove some of the excess wood on the belly side, I go to about 3/4" in the limb area leaving plenty of wood for handle and fades, but I'd check the moisture content before I'd fully reduce their width or begin flexing them at all. I like Hophornbeam down to at least 10-12% before I reduce width, and around 8% to tiller. If it was kept in a dry place for a year, it might already be there.

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

Good advice from Jeff.

Hop Hornbeam dries very slow if not reduce closer to bow dimensions. I’ve had staves in my shop for years that still have to much moisture to flex when I finally did reduce them.

I don’t have a moisture tester, but I can just tell how the draw knife “drags “ through the wood when it isn’t dry.

If you flex it when it still has to much moisture it will take set

Bjrogg

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

Thanks George. So even though this stave is reduced it may be quite awhile before working it further?

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

Reducing it should really speed up the drying time. After a week or two you could put it in a dry heat spot to further speed drying.

I don’t have a moisture tester and never really trusted the ones I have had.

I like to weight the stave. Write it’s weight down on belly. Keep weighing it till it stops losing weight. If it’s in a dry box or inside a vehicle sitting in the sun. I usually take it out at that point and let it reacclimatize and even its moisture out for a few days.

Then it’s ready to work.

Bjrogg

|

|

| From: Bassmaster

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

Jeff I know which is which. What I was referring to above is called every thing from Blue Beach, Iron wood, American Horn Beam, American Hop horn Beam. I have made quite a few bows from it ,and it does tend to check at the knots, bends easy with dry heat, and is good bow. I built one with recurves, and sinew backed. Its one of my personal best bows to date.I let mine dry in 60 degree humidity with the bark on the back, and the end s sealed. Never had a problem with checking except at the knots on only a few.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

Bassman, I was directing my post at Felty, not you. I've heard them both called ironwood, but never heard anyone that truly knows the difference call hornbeam, hophornbeam. They're not even related.

|

|

|

|

| From: Runner

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

"They're not even related."

They actually are and probably more closely than the latin name suggests.

|

|

| From: Bassmaster

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

I have. Research it . It has been called all of the above. Many builders have never used it as a bow wood. Find a piece long enough ,and free of knots which is some times difficult, and it can make a very good bow. I find it around creek bottoms in my area.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

Hornbeam (blue beech) may have been mistakenly called Hophornbeam, but not by anyone I would tend to take advice from. I don't have to research it my friend, I learned the difference between them decades ago. I've made bows with both and have numerous staves of each, hophornbeam and hornbeam, different genus and species, in my shop, all dry, clear, straight, knot free, ready to go. Hornbeam likes to grow near creeks like you said, and while hophornbeam likes to grow moreso higher on hillsides, I've cut them within sight of each other on occasion.

Too much talking. Going to the shop.

|

|

| From: Bassmaster

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

Nice day out . Going to go do some shooting.

|

|

| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 20-Feb-22 |

|

WOW!, Reading this thread reminds of the good old days and those many discussions amongst self bow aficionados working on their projects. Refreshing to say the least to see "the usual suspects" unselfishly providing guidance and wisdom. Carry on good men! TLM

|

|

| From: charley

|

|

|

|

|

|

|

| Date: 21-Feb-22 |

|

Working on my first selfbow right now. Hop hornbeam, super dry, 66", 1 1/2" mid limb. Hits 50lb at 20" now. Could I realistically get a 50#@29-30" bow? Or should I shoot lower. I'd be happy with a little less, I just don't want to fail. Thanks

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 21-Feb-22 |

|

Charley I would like to see another 2” for 30” draw.

We usually say length of handle and fades plus 2x draw length.

So a 5” handle and two 1 1/2” fades = 8” 2x 30=60+8= 68

So I would like to see 68” and a nice bend.

Bjrogg

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 22-Feb-22 |

|

Or, make it 1 3/4-2" wide by 66" long. Somewhere in the equation you need more wood. Be it length or width. It doesn't mean a bow will break if its underbuilt. It just means its not happy and healthy and wont perform like its capable of. You can make what you have work by getting the limbs to bend right up into a bulbous style grip.

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 22-Feb-22 |

|

Yes I’m not saying what you have can’t work. It can, but it will require everything bending just right.

But then that’s always the case.

Bjrogg

|

|

| From: Stickbow Felty

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

Just wondering if you got any further along on your hhb bow Steve?

|

|

| From: wooddamon1

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

Yeah, let's see some ironwood bows!

|

|

| From: Bassmaster

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

My friend in Jan, gifted me 2 nice HH logs. 4 days ago I split one log with a chain saw in half. I took one half log ,and tried to split it with wedges. It did not split straight, but still managed to rough out 2 bows. It sat in my cellar near 5 months with the bark on ,and ends painted. Before I roughed the staves out I checked moisture content at 35+. I have one floor tillered ,and on a form drying. I have been giving it light heat treats each day,and have the moisture down to 20. No cracks. Been working on the other stave to get it to floor tiller, and I will put that one on another form. My cellar stays at 60 mc. I have made a lot of green wood bows that way, and it has always worked out for me.First time for me with HH. It seems similar to birch in some respects.In a couple weeks I will be shooting the first one. Anxious to see how it performs.

|

|

|

|

|

|

|

|

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

I decided to give it to a long time resident of the island. I checked his draw length and all was good until he gave it his best rendition of an English Warbow draw! She popped a 1/4” splinter by about 3” long dead center of the limb but amazingly she stayed together. He was heartbroken and wanted me to try and fix it. I told him I thought it was probably fatal but I’d try. I flooded the crack with c/a glue and clamped it. The next day I put on a sinew patch using titebond 3. Then I wrapped it in serving and flooded it with c/a glue. I retillered the bow and dropped the weight to 48#. She shoots very nicely and so far is holding up. My friend is happy and I’m crossing my fingers:)

|

|

|

|

|

|

| From: wooddamon1

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

Too bad about the splinter, hope she holds up for your buddy. Nice looking bow!

|

|

|

|

|

|

|

|

| From: Ironfist

|

|

|

|

|

|

|

| Date: 07-May-22 |

|

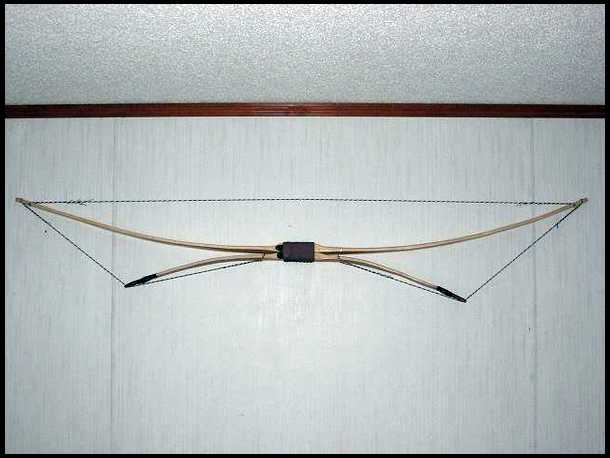

Hop Hornbeam Mi'Kmaw warbow.

|

|

| From: Ironfist

|

|

|

|

|

|

|

| Date: 07-May-22 |

|

I always leave the bark on and seal the ends. Removing HHB bark is something I enjoy doing and digging and ploughing the cambium is all part of the enjoyable process. Yes I am sick lol. All my HHB Warbows are still out there doing well and are over 20 years old.

|

|

|

|

| From: bentstick54

|

|

|

|

|

|

|

| Date: 07-May-22 |

|

Great looking bows guys.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|