| From: Tim Baker

|

|

|

|

|

|

|

| Date: 04-Jan-22 |

|

When there are no straight-ringed red oak, maple of other hardwood boards available check out the 2x4 doug. fir lumber. At about .50 specific gravity it will yield a safe hunting-weight bow if made wide or long enough and crafted carefully.

Ten minutes of peeling through this pile uncovered none without crooked or diving ring lines here and there, or knots of other flaws. But each 2x4's 3.5" width holds 3 or 4 potential bows, so by placing a future bow somewhere along the 96" length of each of them soon found 3 suitable staves... By placing a knot at grip center, where it would be thick enough not to matter, and sliding another future bow right or left to avoid swerving grain, and by settling for a bit shorter bow, three staves were gotten from this 2x4; 72", 67 and 58". $2 per bow.

The 72" is pictured. 40lb at 26", 17 ounces.

Sopping wet from the yard, a one-inch slice from one edge, rough floor tilled green, weighed 30oz. Weighed each day that fell to 26, 23, 21, 20.5 20, 20, dry.

All else equal, choose close-ringed staves with highest % of dark, late wood rings.

|

|

|

|

|

|

|

|

| From: Gray Goose Shaft

|

|

|

|

|

|

|

| Date: 04-Jan-22 |

|

Such confidence, you are temping me to cut out a board bow.

|

|

| From: Flntknp17

|

|

|

|

|

|

|

| Date: 04-Jan-22 |

|

Thanks for the pictures! The local lumberyard is my favorite place to go find a new bow, almost entirely because I was lucky enough to find your writings in the 90s. I still prefer to make board bows over stave bows for a number of reasons.

All of these started out destined to be a baseboard or trim or a piece of a mantle....until I saved them from my local Menard's.

Matt

|

|

| From: B arthur

|

|

|

|

|

|

|

| Date: 04-Jan-22 |

|

Wonderful info. Thank you

|

|

| From: Altitude Sickness

|

|

|

|

|

|

|

| Date: 05-Jan-22 |

|

Nice Flintanpper. I like the tips on the Dark one. I used Black Cherry from lumber I had milled from my trees. Backed it with bamboo as shown by Tim in BB2 I think

|

|

| From: Altitude Sickness

|

|

|

|

|

|

|

| Date: 05-Jan-22 |

|

Oops it was supposed to be this one showing the Black Cherry. Started as kiln dryed rough cut lumber

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 05-Jan-22 |

|

Home Depot has 4X4 Doug fir for about $14, I use this wood to make carpenter bee traps but have see an occasional tight ring almost perfect piece that made me think of arrow shafting. There would be some waste but some good bow staves could be cut from this wood.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 05-Jan-22 |

|

By using the method that Tim is desiring to secure good bow staves you can get a lot of good arrow shafts as well.

Many times the lumber with bigger dimensions 2x6 and so on are better overall because the are typically sawn from the log first.

|

|

| From: N Y Yankee

|

|

|

|

|

|

|

| Date: 05-Jan-22 |

|

Nice to see that wood will make a bow, but couldn't we just put a good backing on a questionable (not ugly) board and make a bow?

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 05-Jan-22 |

|

Off topic.

I'm a retired carpenter from 47 years on the job. As a result I know a little something about wood grain.

When I'm looking for straight tight grained wood in the stud bins at Depot and Lowes, the very first thing I do is eyeball the end grain. That immediately gives me an idea of the 'possibles' to check for face and edge. Sometimes I'll see one that makes the digging worthwhile. But most times not.

Every now and then -make that VERY infrequently- there is a board with perfect tight straight grain end to end and no knots. It's incredible when you find one, kinda like finding a gold nugget. I built the lattice wall of my three small nomadic yurts with those boards. Making a bow out of one of those boards them would be very cool.

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 05-Jan-22 |

|

Eric Krewson's point that 4x4s [and larger] of Doug fir are worth checking out is worth pondering: Especially with a band saw it would be possible to follow the outside surface of the tree from one end to the other, so even if the grain was not perfectly parallel with the board's surface it wouldn't matter. Likely one 4x4 out of ten would yield several perfect staves. Theoretically 9 or so, but 5 or 6 shouldn't be too uncommon.

Bob Rowland's point is a valuable takeaway: " ...the very first thing I do is eyeball the end grain. That immediately gives me an idea of the 'possibles' to check for face and edge..." This is a huge time and work saver.

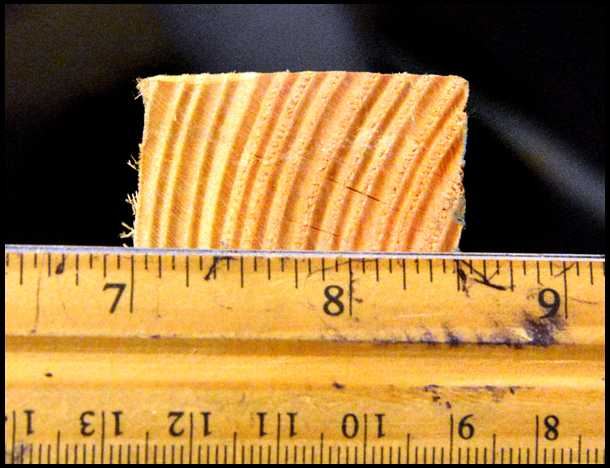

In conifers higher ring count means denser, stronger wood. The 2x4 the 40lb bow of this thread was taken from had a ring count of about 10 per inch, about average, see photo. 20 rings per inch would be better. The bow took just-unbraced set of 1.75, meaning that at 40lb @ 26" the wood was somewhat over-strained.

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 06-Jan-22 |

|

NY Yankee: "...couldn't we just put a backing on a questionable...board and make a bow?"

If for some reason that particular board must be used, yes, otherwise it's cheaper, easier and faster to look deeper into the pile for a sound board.

If a backing is used on low-density wood it should be sinew or rawhide of such.

If a denser wood backing is used its surface should be narrowed (trapped) so an not to overpower the belly, inducing large string follow.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 06-Jan-22 |

|

I appreciate this thread!

I have to say when I make a board bow I want a nearly perfect board with no more than 2 run outs per limb. I favor red oak boards.

Looking at the butt I like rift sawn so I don't have to chase any rings.

I've made so many board bows. I've lost track.

Permit me an editorial comment.

Special thanks to Tim for showing me the way. Long about 1993 I ran out of dry log staves and then I picked up a copy of TBB2 and the rest is history.

Glad you are back Tim.

Anyway, I've embarrassed him enough. :)

Jawge

|

|

| From: neuse

|

|

|

|

|

|

|

| Date: 07-Jan-22 |

|

I enjoy these bow building topics. Thanks for posting.

|

|

| From: Catskills

|

|

|

|

|

|

|

| Date: 07-Jan-22 |

|

Great Info. As a longtime carpenter who has yet to build a bow, I find it fascinating.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 07-Jan-22 |

|

I like clear osage boards with no runout... with a thin coat of bamboo on em.

|

|

| From: Arvin

|

|

|

|

|

|

|

| Date: 07-Jan-22 |

|

I like straight grain staves with no runout. The bow having one growth ring on the belly and one on the back of a selfbow backed by bamboo. That’s taking straight grain to a new level. It can be done but you better have a good stave and be handy with a heat gun. Arvin

|

|

| From: Arvin

|

|

|

|

|

|

|

| Date: 07-Jan-22 |

|

I like straight grain staves with no runout. The bow having one growth ring on the belly and one on the back of a selfbow backed by bamboo. That’s taking straight grain to a new level. It can be done but you better have a good stave and be handy with a heat gun. Arvin

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 07-Jan-22 |

|

When placing the future bow on the 2x4 a small hard knot was allowed, about one foot from a future tip, thinking that being on the belly, in compression only, there'd be no problem. But during final tillering the spokeshave snagged on upward-pointing grain around the knot and ripped a small chunk of wood free. Should have used a fine rasp on that area instead of a blade.

Applied a few drops of super-glue to the area and let it soak in and harden, then a few drops of epoxy to fill the concavity.

Can now safely Eiffel tower the outer limb, lowering mass there for better performance.

Working on the second bow from that 2x4, will report.

|

|

|

|

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 12-Jan-22 |

|

Here's the center stave extracted from the above 2x4. It's flat- ringed, so worked it down to one ring, a bit of early wood left to be scraped fee, or not--it doesn't matter if left on.

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 19-Jan-22 |

|

Testing of the second stave from the above Doug. fir 2x4 was interrupted due to testing of combed flax fibers as a back protector - - see the One Dollar Pine Board Stave thread:

https://leatherwall.bowsite.com/tf/lw/thread2.cfm? forum=23&threadid=330698&messages=50&CATEGORY=4

As part of the new testing no flax was applied to the second 2x4 stave and it was pulled to it's breaking point, 37lb at 28".

The third stave from that 2x4 has been floor tillered and will be given an once or so combed flax layer on its back, then tillered either to 55lb at 28" or it's breaking point.

Why bother? Flax, and other vegetable fibers are a fully paleo way to protect suspect backs or weak-wood bows, and for all we know such was used in the distant past. In any case, discovering if and how well the material would have worked is interesting, and worth trying now.

The stave has a few serious fiber violations, but flax fiber held the one-dollar pine board bow together, despite similar problems, so good chance it will here too.

The third stave and it's problems:

|

|

|

|

|

|

|

|

| From: MCNSC

|

|

|

|

|

|

|

| Date: 19-Jan-22 |

|

Tim, thanks for the thread. Sure brings back memories as these type threads used to be quite common. I’ve never built a board bow, I did attempt and fail at a couple from staves many years ago. I’ve always admired Bamboo backed bows , mostly because I just think they look nice. Heck , maybe I’ll dig out my books and give it a shot.

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 23-Jan-22 |

|

The third stave from the above 2x4 had fiber-violation flaws too severe for a pure self bow, so 1 1/4 ounces of combed flax was applied to the back, as if sinew-backing, with slightly more added over the above-pictured problem areas. Three days to dry, then final tillered and tested.

It reached 50# at 24.5", 60# at 28.5", then taken to 31" and an estimated 65#-- the scale won't read past 60#. Just-unbraced set 3.5" That degree of set shows the .50sg fir to be far over-strained, partly due to the wood itself and possibly partly due to the strong-than-fir flax backing overpowering the belly. Possibly less flax would have protected the bow and yielded less set.

Three main takeaways form this. and the earlier one-dollar-pine-stave thread: A surprisingly small amount of flax fiber, a pure paleo, process, protects weak or defective staves. More flax than needed induces cast-robbing set. Securing and applying the flax is a big pain, so unless desperate for a stave it's better to spend the time searching for a sound stave.

|

|

|

|

|

|

|

|

| From: RyanY

|

|

|

|

|

|

|

| Date: 23-Jan-22 |

|

Good to see you at it Tim.

I think there are too many variables to blame the flax on any excess set. It seems likely that the fir is too light for this draw weight and I would say your tiller shape is bending too much in middle by my eye. I would expect a more elliptical shape with your width profile for even strain.

If the flax is overpowering the fir belly then it could be mitigated with some trapping quite easily.

Love these experiments.

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 24-Jan-22 |

|

RyanY: Good eye: Yes, it's bending too much in the middle. The earlier-pictured fiber flaws rested at each mid limb, so full bend there was avoided.

The flax wasn't blamed for the excessive set, just suggested as a partial cause. As you suspected the wood itself is the biggest cause--.50sg wood taken to 65# at 31# will take huge set, if it holds together at all. And yes, the over-worked center increased set too. The bow had three good reasons to blow but that 1.25 oz of flax, 1/20th the mass of the bow, wouldn't let it go. That stave is an example of where flax protection is appropriate, and a better choice than sinew or rawhide.

Yes, once too-early set is noticed the back can be trapped to reduce further set, or if excessive set is suspected less flax could be applied to start with. Once familiar with the process the correct amount of flax for each situation would be known.

|

|

| From: Steve Milbocker

|

|

|

|

|

|

|

| Date: 24-Jan-22 |

|

Hey Tim, a question. I recently built a mulberry bow for my stepdaughter, it came from a branch on a tree where she grew up. I was shooting for 40# but got a thin spot and had to chase it out during the tiller. It ended up 30#@28”. The bow is 60”. 1.25” at the handle tapering to 1/4” tips. It weighs 10 oz. It sounds like I could boost the weight with the flax. How much would you suggest using to boost this bows draw weight another 10 lbs or so?

|

|

| From: txdm

|

|

|

|

|

|

|

| Date: 24-Jan-22 |

|

Tim have you tried any toasting/fire hardening on these $2 bow bellies? Also interested in if you've seen any improvement from burnishing the backs (aside from general resistance to dings and dents)

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 24-Jan-22 |

|

Steve: Your situation--where the bow has value apart from utility--is an example of a rare case where adding flax to a back is appropriate. Based on two experiences so far, especially re the one-dollar-pine bow thread, I'd estimate that 1/3 of an ounce of evenly applied flax would do. If not quite enough a bit more could be added later. If you decide to try this size the back well, let the hide glue be a touch thinner than for sinew, let the flax strands be quite thin: hide glue doesn't wet flax easily--thick strands can seem saturated with glue but be dry at center, only the surface flax working. Sinew is a better option if you have the sinew or don't mind buying it. Sinew would cost $50 or more, about two dollars for flax.

Txdm: The main danger with these weak-wood or compromised staves is that they'd break in tension, therefor the flax. But flax, being stronger than the wood, could induce added set, so fire hardening could possibly slow that. Haven't tested this enough to say how well. Same with back burnishing--not enough sound testing to say.

|

|

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 24-Jan-22 |

|

Txdm: "Tim have you tried any toasting/fire hardening on those $2 bow bellies?"I tried, but haven't quite perfected the process yet. Advice welcomed.

|

|

| From: txdm

|

|

|

|

|

|

|

| Date: 25-Jan-22 |

|

Hahah, it's a classic Shou Sugi Ban finish!

Maybe I should have asked about "toasting" instead of fire hardening.

|

|

| From: Tim Baker

|

|

|

|

|

|

|

| Date: 26-Jan-22 |

|

txdm: Actually it's a classic burnt-down fence. Saw it on the way home and couldn't resist joshing the heat-treating community.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|