| From: Rooty

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

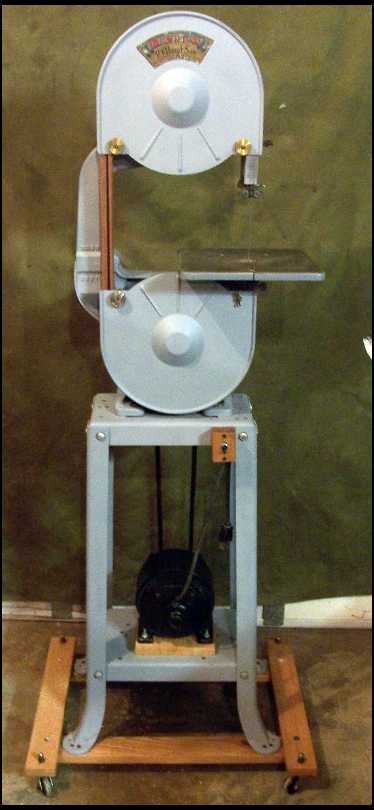

Waiting for blades

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

I broke this blade with a stave. Very brittle. 40's saw for a 40's bow in progress.

|

|

| From: MikeT

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

I`m in thanks that looks like a great tool what a great find. I`m a tool guy and I dont have one of those. I`m also in for that little outboard, the rounded housing looks like my old 78 8 hp Mariner

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

Where's the stave? A boo backing ain't no stave brudda.

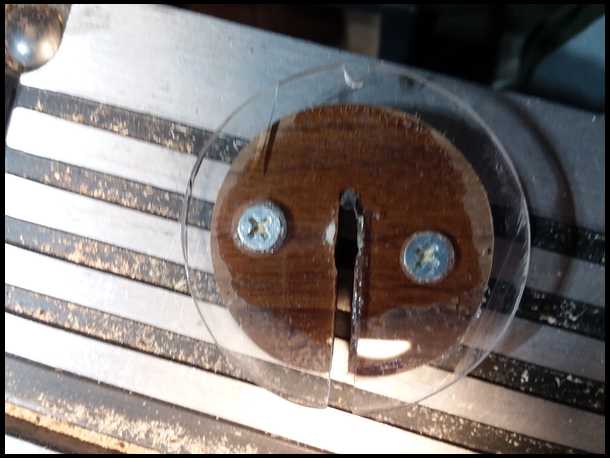

Why is there no insert in the table? If it wasn't there as the cut was being made, I wouldn't be surprised at all that the blade broke.... or worse... lucky you weren't injured. Never run that saw without a blade insert. They're cheap. Blade guide should be set closer to the work too.

I've never broken a single bandsaw blade and I've been doing it for decades, but I tend to use the widest strongest blades i can per application on my saw.

I'm guessing you didn't break the blade sawing that bamboo 'stave'? Bamboo cuts like butter.

What were you sawing? And why did it break?

You should have spares. You should never have to wait for blades.... or spacers... or guides... or bearings... or wheels... etc. Cheap, necessary stuff.

|

|

| From: Deno

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

|

|

| From: MikeT

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

OK, i`m not in till you get the parts, and I`m not getting any younger, just sayin,lol

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

Looks like an Evinrude to me!

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

Here's my little one. I have three others of similar vintage--a 12, 13, and 14".

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

I have an old Craftsman i rebuilt i put ball bearing guides in it and a new lower wheel bearing in it . I make my own blades up i have a pack of blade material form my former job and there was a welder built on the saw it was DOALL band saw .Mine are 80 inch

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

80" is standard for several decades of Craftsman saws. OLder than 1980 or so are good saws.

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 17-Dec-21 |

|

If an insert is no available for that saw. Cut a piece of bow material the diameter of that hole & about the thickness. Sand until level then cut the slot with the blade for Zero clearance. I have to make mine so I cut out 3 & hung 2 on a wire on the stand. Wish I could weld a blade. I have a second little saw that takes an odd size I haven't been able to find. >>>----> Ken

|

|

| From: Pdiddly2

|

|

|

|

|

|

|

| Date: 18-Dec-21 |

|

I bet that's a 4HP Evinrude with no shift that spins for reverse. I think I see the throttle handle on the side opposite the tiller. Ask me how I know this...

Perhaps Cameron took the insert out once the blade was pooched...he is a skilled craftsman.

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 18-Dec-21 |

|

Holy cow Jeff D. Scold someone else. The blade was very brittle , crumbled. Since my haste in trying before checking everything over. I now have a good understanding of all the adjustments. Thanks Joe I have silver solder. The term stave includes man made.

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 18-Dec-21 |

|

Make of unit falls under the Duro blanket of tools.4

|

|

| From: Jon Stewart

|

|

|

|

|

|

|

| Date: 18-Dec-21 |

|

Inserts are easy to make . I made a couple using black walnut and plexiglass. I am surprised you don't have a shop in the area that can't make new blades for you. I have 3 or 4 made up at a time for $8.00 each.

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 18-Dec-21 |

|

There's several bandsaw mills in the area. I haven't a chance to source yet. Thanks on pic. I have played with the table. Slot in table does not line up blade.

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 18-Dec-21 |

|

Peter your right on the outboard.

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 18-Dec-21 |

|

Tooney

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 18-Dec-21 |

|

All you need is a small jig made from a scrap pc of angle iron . then just put the jig in a vise and grind the blades on a angle it s not exact and silver solder them together . Then anneal them after silver soldering . they will hold . you can use small c clamps to hold the blade in place or drill and tap the angle then use a washer and bolt to hold the blade in place .

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 20-Dec-21 |

|

Thanks Joe

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 20-Dec-21 |

|

I am not much for waiting. Cut it out with a sawzall.

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 20-Dec-21 |

|

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 20-Dec-21 |

|

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|