| From: static

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

Where to buy?

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

3Rivers used to sell them but I'm not sure they are still in business.

|

|

| From: Rooty

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

I have one. I am not a fan. However Justin Newell likes his.

|

|

| From: Dan In MI

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

They've been out of biz for few years now.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

My experience is that you can easily build a taper tool that works better for less money.

But that's just my point of view.

|

|

| From: Harleywriter

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

I’ve had one for years and it works fine. It takes a little fooling with but then it does a nice job.

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

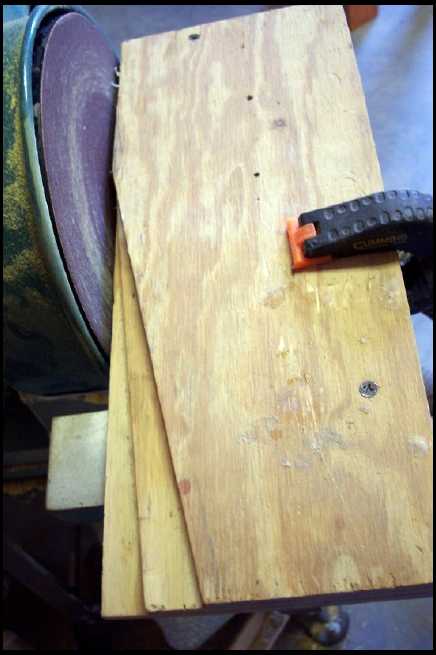

I just made a jig for my bench disc/belt sander

|

|

|

|

| From: Jim

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

Buy Rooty’s if he’ll sell it to you. I have two and love them.

|

|

| From: Scoop

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

Had mine for years and tapered a lot of arrows. Works fine.

|

|

| From: newell38

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

I have 2 and I absolutely love them. I have one set up for point tapers and one set up for nocks. Once you get them dialed in they’re fantastic. I’ve been using mine since 04 and they’ve done countless shafts. I also have a few of the horizon taper machines and they work good too but I like the woodchuck better. If you heat up the metal disc before you stick the adhesive sanding disc on, it’ll stay on no matter what. I taper shafts in my garage in the winter when it’s well below freezing without any issues. They’re great machines if you’re patient with them and get them figured out. I’m always looking for spares if anyone has an extra laying around!

|

|

| From: Rock121

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

I think I have one somewhere I will send you if you want it...Let me dig it out

|

|

| From: babysaph

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

Heck I use the hand held ones and they do just fine.

|

|

| From: Corax_latrans

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

I’m still trying to figure mine out…

Thus far, I am pretty sure that it’s a perfectly good tool and the operator needs a little more training. Not saying that an enterprising person couldn’t build something extremely comparable at a much lower cost, but I really don’t think there are any flies on it.

But hey, silly me… There I go assuming that it’s probably operator error again…

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

You need to learn how to use the tool. I found my woodchuck is actually a fine tool for production work. Not so great for hand spinning, unless you have just the right amount of water on your spinning hand for gription on the shafts, or they can pop out of the vee groove in the base. I bypass that goofy slow technique and power spin for production.

How? Use a battery drill. Chuck one end of the raw shaft into the Jacobs chuck. Power on the point taper while using a gloved hand to force the shaft down into the vee groove so it can't possibly skip out.

Glue on your points, blunts and target points work equally well. Chuck the point into the chuck and spin on the nock taper using the same gloved technique.

Easy as can be. Fast, efficient, accurate, and fun, instead of tedious. The tool is like manna from heaven.

Contact cement works great when you redo the sanding disks. I make sanding discs out of sanding belts.

|

|

| From: MStyles

|

|

|

|

|

|

|

| Date: 24-Nov-21 |

|

It’s all about getting them set up, which has already been said. Great tool.

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

You can buy a cheap Harbor Freight disc sander, make a simple jug to go on the miter table and make perfect tapers at a fraction of the cost of a Woodchuck. After you get your jig angles down you are done, no more adjustment, ever, no matter what kind of shaft you put through it.

My jig is on a 6X48 sander that I use for bowmaking and a variety of things in my shop.

$89.99 at Harbor Freight plus you can sharpen your broadheads on it.

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

My simple jig, I have had a variety of belt/disc sanders over the years, every one had a shaft taper jig on it.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

Yep....what Eric said.

|

|

| From: leftwing

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

Very innovative Eric, I like it!

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

I have a jig made to slide in the groove on my table saw. Put in the 10 inch sanding disk instead of a blade and you can taper a dozen arrows in less than 10 minutes, and they are perfect.

|

|

| From: Scoop

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

I do like the idea of also using the belt/disc sander and jig for doing 10-12 inch nock and point tapers.

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

I use this for the shaft tapers, it works but is not as precise as a dedicated jig. I have done enough shafts to eyeball the results, get them close and finish off by spinning the shaft in a drill and using hand sanding.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

I like using the adjustable 'stop' on my woodchuck. Tapers are exact one to the next. No need to bite off a point too long.

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

I do similar Eric, but not the kind of taper I think he was asking about.

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

Oh, and if you clamp a support piece at the back end of the belt to allow the shaft to ride on you get real shaft to shaft consistancy.

|

|

| From: Tater

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

I've had my Woodchuck for more than 20 years done hundreds of shafts, great tool, made in the USA.

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

I always wanted one...but just too expensive for me.

|

|

| From: dnovo

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

I bought mine many years ago. Price wasn’t bad then. I understand they’re no longer in business. I think it’s a great tool.

|

|

| From: Andy Man

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

If you read the instructions and take your time setting it up

It does a great job -I do about a 100 every year with mine since the 80's I think

if doing commercial would look into a belt/disc sander rig

|

|

| From: Jon Stewart

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

Have one, hate it. Dont use it

|

|

| From: shortdraw

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

Jon, if you want rid of it I would take it.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 25-Nov-21 |

|

Yup I suggest sell it Jon. You could do that right now and be done with being vexed. ha

|

|

| From: Jon Stewart

|

|

|

|

|

|

|

| Date: 26-Nov-21 |

|

Buddy gave it to me as he didn't like it either. Will have to check with him first to see if he wants it back. I just couldn't get it set up right I guess.

|

|

| From: Phil Magistro

|

|

|

|

|

|

|

| Date: 26-Nov-21 |

|

I've had one for a long, long time. Use it for tapers on wood and to true up the ends when I cut aluminum or carbons.

|

|

| From: bodymanbowyer

|

|

|

|

|

|

|

| Date: 26-Nov-21 |

|

The PackRat. A little bit of everything, made this one. JF

|

|

|

|

|

|

|

|

| From: Selden Slider

|

|

|

|

|

|

|

| Date: 26-Nov-21 |

|

I have one I got in a trade. Haven't used it for quite some time. It did make great tapers. Frank

|

|

| From: Dan In MI

|

|

|

|

|

|

|

| Date: 26-Nov-21 |

|

I have been toying with making one. So far I have seen versions of almost every idea I have had.

|

|

| From: Corax_latrans

|

|

|

|

|

|

|

| Date: 26-Nov-21 |

|

Well, I suppose there aren’t all that many ways to skin that particular cat….. ;)

|

|

| From: sagebrush

|

|

|

|

|

|

|

| Date: 27-Nov-21 |

|

I got a point and nock end tapering tool a while back that works with a drill.fast and simple,all come out the same

|

|

| From: N Y Yankee

|

|

|

|

|

|

|

| Date: 27-Nov-21 |

|

The pencil sharpener type hand tools work OK on POC shafts but try it on hickory or fir and you get a rough, torn up taper. They also have a habit of making an off-centerline taper. Power sanding is the only way to go. I could never pay the $200 plus for a woodchuck tool. I got the 89 dollar sander from Harbor Freight and made a jig. It works just fine. And yes, you can sharpen knives and broadheads with it.

|

|

| From: Phil Magistro

|

|

|

|

|

|

|

| Date: 27-Nov-21 |

|

The nice thing about the Woodchuck (and I would guess homemade jigs) is that it’s easy to cut the taper with a slight shoulder so the field point aligns perfectly with the shaft diameter. When to run a finger over the point and shaft there is no edge. Also the shoulder provides, in my opinion, some extra support for times the field point hits something hard.

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 27-Nov-21 |

|

I have one also. Used it for years but lately switched to the Top Hat system, no point tapers. Only use it for nock tapers now. If I recall it wasn’t that hard to setup. I set mine up to undercut the shaft a bit so points are flush fit to shaft.

|

|

| From: Corax_latrans

|

|

|

|

|

|

|

| Date: 27-Nov-21 |

|

“ I could never pay the $200 plus for a woodchuck tool.”

I’m sure that the demise of the company has a lot more to do with the fact that not everybody HAS TO shoot wood anymore, but that kind of a price tag certainly didn’t help them any!

I got mine in a big box of used gear which included the Woodchuck, a feather burner, a Bitz, a string making jig, and an arrow length measurement/cut off device… Oh, and a spine tester and an Ace arrow straightener. And a Woodchuck shaft taper jig.

I think I paid $100 for the lot, so….

:D

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|