| From: JusPassin

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Usually folks see footed shafts and are pretty fond of them.

We all know they are supposed to strengthen the arrow tips. But how about appearance?

There are a variety of ways to build them. The 4 winged method is likely the most well known, and it is attractive, but a challenge to make without special jigs.

Less common is the two winged version. It is easily made without the special jigs and is still good looking.

And least of all is the single scarf joint. Very easy to do, but perhaps the least attractive.

I don't think any argument can be made against the strength of any of them. I have tried shooting them into concrete walls. They of course shatter, but the glue joints never once have been the weak point.

How many of you make and/or shoot footed wood arrows?

|

|

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Bruce:

I have shot nothing but footed arrows since about 1990. I love them, also made them commercially for over 25 years. One thing I learned is, its difficult to make close weights unless you weigh each foot in each dozen and group them. I fixed that problem by going to laminated woods like actionwood and Dymondwood, the weight uniformity is extremely close.

Bob

|

|

|

|

| From: Bill Rickvalsky

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

I usually simulate somewhat the appearance of a footing by the way I stain my shafts when I make up my wood arrows. I would really like to attempt some real footings one of these days. I'll have to Google some tutorials.

|

|

| From: Andy Man

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

I used to slit them and put in a hard wood strip like a self nock kinda deal

somebody used that circuit board stuff

|

|

| From: Snag

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Archery Past sells footed shafts.

|

|

| From: Jon Stewart

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

They are a labor love for sure. The top one is unique. The bottom one is my carp fishing arrow.

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Todd: Try "Gray Goose Arrows" in Mesa Arizona he is the one that bought my business and is doing a really great job. \ Bob

|

|

| From: Corax_latrans

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

I will be well and truly damned if I can figure out how you guys get that spiral effect. Seems like it must take some mighty powerful black magic to do that!!

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Did the spiral by accident one time. Sanding the spinning arrow and it heated and twisted.

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Good reminder Jim, I forgot about the repair arrow as a footing idea.

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Making footed arrows has been one of those projects that just seems to have not gotten off the ground for me. I even have one of those jigs that 3R sells. Don’t know if the foot would save the arrows around our rocks but they look cool. Maybe now that the “winter visitors” are leaving I can find space at our woodshop to make some. Just got me 2 Dozen Cedars from Wapiti, spine and weight matched, beautiful shafts.

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Here is one I did just for kicks/giggles. Bob

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Here is the other end

Bob

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Here is another!

Bob

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Here is another!

Bob

|

|

| From: Corax_latrans

|

|

|

|

|

|

|

| Date: 05-May-22 |

|

Well, now you’re just showin’ off….

LOL. That is pretty incredibly cool, Bob!

|

|

|

|

| From: Jon Stewart

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

Geez Jim Davis. I tell everyone that it is carefully chiseled, lol.

Yup that spiral happens when you spin the shaft while sanding and it gets warm and twists.

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

We all get carried away sometimes Bob. This is all done with scarf joints.

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

You bet Bruce! half the fun is experimenting with different things.

Bob

|

|

| From: mgmicky

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

Those are great looking arrows guys. For those of you that use the dymondwood or similar laminates, where do you buy the dowels to make the footings?

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

Mike: I didn't use dowels, I cut 3/8" square pieces and turned them round after gluing to the shaft.

Bob

|

|

|

|

| From: mgmicky

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

For those of us that don’t have the tools or know how, is there a place to buy the laminates already cut as a 11/32 dowel? I did a quick google search and did not find anything…

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

MG, it's more fuss to match up two round pieces than to work down a square to match a round, at least IMO...

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

MG: I agree with Jim, glue the square on first, then using a block plane you just start cutting off corners until its almost round. Its easier to keep the shaft straight that way. If your plane blade is sharp the task will go quickly. then chuck the shaft in a drill and finish turning with sandpaper until its round and the size you want. If you make a sanding "book" two pieces of wood hinged together with hole and sand paper, you can make them any size you want and keep them uniform. Bob

|

|

| From: mgmicky

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

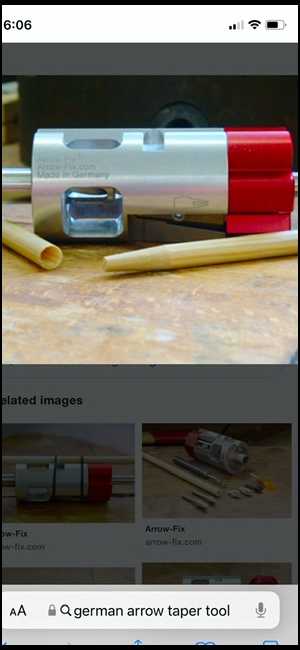

Ok, I appreciate the input on the block plane. I was thinking about buying one of those German tools that does nock and point tapers as well as hollow out sections for making the footings. I thought this might work well with a dymondwood like dowel…

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

I don't think "one of those German tools" which shall remain nameless, would help to work down a footing.

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

Lee-Neilson has the plane you need. Not cheap but the A2 blade holds an edge. For the price of that unnamed tool you can almost buy the “Scropion “ from “Traditional Archery Products”. That and the special blade for your table saw will run about $700. I have watched his video a few times. Makes cutting the shaft a two minute job. Ya, I thought real hard about buying the setup, choose the 3R jig for a $100 bucks.

|

|

| From: mgmicky

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

This one

|

|

| From: Corax_latrans

|

|

|

|

|

|

|

| Date: 06-May-22 |

|

Isn’t there a guy in the US who sells wood footings that just glue onto a standard taper?

I think you could buy a lot of those footings for $100.

LOL.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 07-May-22 |

|

Corax, Jim Davis, the second poster on this thread, sells reparrows. Those are reparrows in the photo.

|

|

| From: trad_bowhunter1965

|

|

|

|

|

|

|

| Date: 07-May-22 |

|

I use the Arrow-fix a lot to repair arrow it works awesome paid for itself. I will have to try some hard wood footing.

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 10-May-22 |

|

Long time absent due to family health problems Great to be back. Finally making more footed arrows. Australian silky oak on Douglas fir.Great to see Bobs work and others too .I recently scored some more Douglas fir and some Baltic pine.That comment about weight and spine consistency is so true. One batch I made a few years ago of 360 shafts only gave me 4 sets of matched spine and weight arrows. They shot good.I have lots of odds and ends and these will match other shafts in my next batch.I recently discovered Manchu arrows and whilst these are not footed they have tanged arrow heads. These tangs are about 1/8 "dia and up too 6' long.The shafts are then bound with a silk wrap of about 2' behind the point.I made one and shot it into a cinder block . I also tried one of my footed arrows.The Manchu style tanged arrow was a lot stronger.Who would have thought. Cheers Osr

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 11-May-22 |

|

My current batch

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|