| From: CStyles

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

I was wondering who on here makes their own wood shafts? Favorite wood? Method used? It can be really cheap. I paid $7 for a straight grained poplar board at Menards. Got 15 shafts out of it. All spine between 42 and 48 lbs. 13 completed arrows weight between 480 and 490 grains. The remaining 2 one is 475 and the other is 493. I use my bandsaw to slice up blanks, Hand plane to get octagonal sections, and spin them with a drill thru a jig I set up on my belt sander. They are the arrows with the chartreuse feathers in the left side of the quiver.

|

|

| From: felipe

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Not yet but on my list. Nice looking arrows...

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Ain't costing him a dime. Ya don't figure time as money when it's something you do to build skills or for enjoyment and personal reward. Time creating and crafting for your own use isnt time or money wasted. It's time well spent. Time wasted is time spent watching mindless tv, sports, Fakebook or posing on the Leatherwall.

Nice arrows Chuck.

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

I would try to make my own, cause I'm almost certain these folks making 30 bucks an hour aren't worth it any more than I am, lol.

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Good job. I have been wanting to try that but I am not confident in my wood picking abilities. What diameter did you turn them to, to get that weight from Popular. I am amazed they came out that even in weight & spine. >>>----> Ken

|

|

| From: Nemah

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

I’ve made hundreds that way. I use a lot of Douglas Fir, living in WA state. One source of good heavy wood is used hockey sticks from Good Will. Another is the moulding available at Habitat for Humanity. I run the 3/8” squared strips thru a jig that attaches to my router table. I have a 3/8” square socket that the strips fit into and simply push them into the jig with a drill. Richard

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

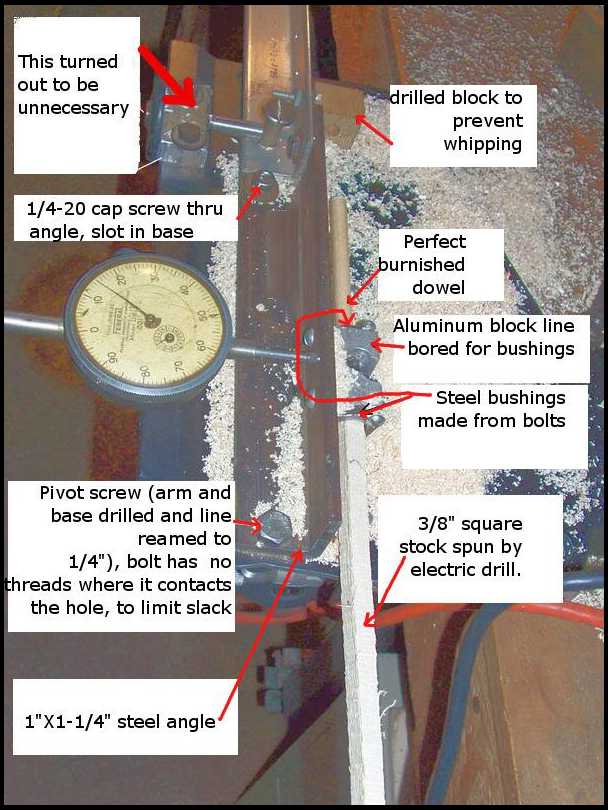

Y'all have seen my setup, but here it is again.

|

|

|

|

|

|

| From: Jon Stewart

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Buddy has a double cut Verita dowel maker. We nock out a bunch of shafts when we get together and about half are good for arrows and the other half are good for tomato stakes. I also 4 point foot some of my arrows .

|

|

| From: Chairman

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

I use a homemade router jig and taper the tail, they look like factory. I like Doug fir if I can find fine grained trim grade for free or nearly free. Poplar for a distant second. I don’t shoot heavy enough bows to use hickory or maple or ash gpp gets way out of hand for my taste.

|

|

| From: Bill Rickvalsky

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Although I am a diehard wood arrow shooter I have never tried making the actual shafts. I will have to look into it. How do you choose a board if you are targeting a particular range of spine? That is one aspect of it that always gets me scratching my head. Or do you just make a bunch of shafts and sort out the various spines?

I always get a chuckle when peopl want to put a value on a persons time to add to the cost of something you do for a hobby or enjoyment. If you're doing it for fun don't you actually receive value back rather than spend it?

|

|

| From: Nemophilist

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

I've made my own wood shafts off and on, but not all the time. I just used an arrow shaft plane after I cut 3/8" square strips.

|

|

| From: babysaph

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Very cool. How straight are they?

|

|

| From: babysaph

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Very cool. How straight are they?

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Nice arrows. I thought about making shafts, probably should have but I am not a one shaft material or bow person. Besides the way I shoot I would be so busy making arrows I would not have time for my other hobbies.

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

As far as aiming for a particular spine range, even factories just sort them afterward. Of course some woods are stiffer than others, but I stick to spruce or D. fir. I buy the spruce at a local building supply dealer. They let me pick through 1x8s and 1x10s for the clearest I can find.

I only buy a board once in a long while, because I can get hundreds of arrows out of good board and I don't need that many.

|

|

| From: AK Pathfinder

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

I copied Jim's jig and it works great. You have to mess with it a bit to get the router bit set in just the right place but once you do it turns out great shafting. How straight they are is more a mater of how good you are at selecting wood than anything. along with sources mentioned I get a fair bit of wood from old doors and siding made from fir and hemlock. I found a sourse of rough cut spruce near where I am and I have a neighbor with a saw mill...whenever I'm cutting firewood and run into a good looking log I will bring a 4 foot chunk home to run through his saw. If it's good I make arrows if not, it's firewood. Jim came up with a great design and I thank him again for generously putting his design out there for others to use.

|

|

| From: Brian B

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

Hi Chuck, Nice looking arrows You made there. I'm sure it was a labor of love also. Many years ago, I made some arrows from ripped up oak wood flooring. Made some 30" square dowels, then planned them down to 8 sided, and so on and so forth. The oak was not fun or easy to work, but it was a kind of fun project. I never hunted with them, I remember mounting a snuffer on one of them, and from what I remember it flew fair @ best, and I made some arrows from cattail reeds.

|

|

| From: dnovo

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

I've got a stack of fid stair treads and risiers I took out of an older house a few years back when we put in new finished stairs. The boards I took out have some of the straightest grain I've ever seen. Older good quality wood. I've been saving them to experiment with making arrows when I retire which is in about 3 months.

|

|

| From: Juancho

|

|

|

|

|

|

|

| Date: 13-Apr-22 |

|

I am drying some ash that I plan to turn into shafts this summer. I made my own jig for the router and I'll post the results when I'm done. All my ash trees were victims of the ash borer beetle, so sadly, they're all coming down. I plan to take them to the mill to turn into 5/8" boards , that will latter be planed to 1/2" , cut into 1/2" square strips , and run thru my jig to make shafts. Never made my own shafts , so is about time I do.

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Juancho, consider 3/8 squares to make arrows. Less waste and can be poked into the 3/8 square ratchet hole in an Allen or Torx adapter that can then be chucked in a drill.

|

|

| From: bowhunt

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Closest I got to making wood arrows from board lumber was buying 3/8th ramin wood dowels and finishing them out.I am sure the spines and weights varied.But it was just a home boy project and the arrows looked nice and were very heavy no doubt.Thy were kinda fat But I was shooting heavy bows and they flew descent with big banana fletchings.

Other than that I bought spine and weight matched cedar shafts and hexashafts and made them up.

|

|

| From: CStyles

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Oh boy, so I could work more and just buy them! The idea is to do something you enjoy in your down time. Most of the time is done while watching TV. In the the last year I have bought 3 dozen POC's and a dozen Douglas fir shafts. I also made a dozen hickory shafts prior to this board. Yes I have a lot of arrows. I cut the board into nominally 3/8" blanks. I use my jig to sand close to 11/32 round. I hand sand to match spine and weight. I have 10-12 minutes time in each finished shaft. Leisure time. They are very straight after I hand straighten them, same as I do with bought shafts. I found good poplar to be very durable. Doug fir is great too. I have also used Select Pine. Chuck S

|

|

| From: Live2Hunt

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Been looking into this the past few months. Just trying to figure out the best method/setup I have available. I am intrigued with the table saw jig method and was going to give it a try when I can get some of my own time to do it!!!

|

|

| From: NYBowhunter

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Nice arrows! I've made dozens of poplar shafts from rough cut and standard board from the big box stores. They typically spine out close to the same. I tend to so this work right after deer season is over and find it to be a great use of my time. And keeps me out of the wife's hair.

|

|

| From: arlone

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

I haven't gotten to making shafts, still buy bare shafts when I need/want to make arrows. Those are nice looking arrows Chuck and a beautiful raw shaft Jim, love that grain.

|

|

| From: oldhunter1942

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

I have made shafts, switched to aluminum and carbon, going back to cedar. I just dont like carbon for some reason.

|

|

| From: Hunter Dave

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Very nice arrows, Chuck!

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Started making shafts from 8/4 s4s boards in 2004. Rip to 1/2" squares and High speed power drill those blanks through a Veritas doweler. ~= 1000 hickory> doug fir> cedar. Wood is all I shoot.

|

|

| From: badger

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

I usually try to select clear fine grained doug fir, I go for the denser pieces. I can usually get 11/32 shafts out of it that will spine up to about 75#. I have made a number of different devices for turning arrows down. Larch is another good arrow wood often over looked.

|

|

| From: Bootaka

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

I used to make my own out of boards or dowels from from ace hardware, turned them down with a .125" of steel with 11/32 mickey cut outs and a hand drill. feathers from my macaw and jb weld for points.

|

|

| From: CStyles

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

For the guys that use the Veritas doweler. Can you adjust it to get 11/32 diameter? How is the finish on the dowels, need much sanding? Any problem with grain tearout on hickory or Doug fir? Thought about getting one a number of times. Chuck S

|

|

| From: Jon Stewart

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Best to google for complete info. You can turn from 1/4" to 1". The finish is good if you run the wood thru at a steady medium pace. If you run it thru too fast you get rings.

I have a 5/16" V-cut in a couple of 1 by 4's ,put sand paper in the v-cut board and run the dowel thru using my battery op drill.

Takes time to learn it. It is my buddies and he sets it up. I just use it.

I know he has paid for it many times over from selling wood shafts.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Jon, adjusting the planes on the Veritas doweler will yield any diameter you dial in. I've made them from hickory to a bit over a 1/4" and all species to just over 23/64ths.

Honed blades will yield a smooth finish on the shafts that doesn't need sanding. However I spine mine by spin sanding them in a drill.

The key to 'no tearout' is 'HONED' blades. I use my green DMT on them and that's plenty good. Keep them both honed and even cedar will not tear out. You'll know when they need honing because of the feel when feeding in the blank, and the finish on the newly doweled shaft will be less than smooth.

Lastly, I HIGHLY recommend you buy one based on all the pleasure I have had making arrows from scratch. Nothing beats it. Good luck.

|

|

| From: trad_bowhunter1965

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

It's on my list to do once I retire looking at one of those Veritas Dowel Maker I see Lee Valle carries.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Also, I mount an 'anti wobble' guide from 1/2" tubing that is just under arrow length, behind the tool so it catches the emerging shaft. Mount it so it's on the axis of the shaft. You need that guide tube to prevent the emerging shaft from whipping round and breaking. I leave a couple inches between the tube and the tool so I can manipulate the shaft if necessary.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

I've made probably 1000 arrows with mine over the last 18 years. It's a great tool totally worth the money.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Lastly, get the 3/8ths insert.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

I've hand planed then from board stock, white pine and other woods. I've also made many natural shoot shafts. Info on my site.

http://traditionalarchery101.com

Jawge

|

|

| From: Caughtandhobble

|

|

|

|

|

|

|

| Date: 14-Apr-22 |

|

Chuck,thanks for sharing. I never see shafts made like that, granted I don't know much about wood shafts: )

|

|

|

|

| From: Renior76

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

Very Cool! Making things on your own brings "next level" satisfaction. Arrows are on my list...

|

|

| From: fiddlebow

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

Very impressive! I’ve always enjoyed making my wood arrows, but I never considered making my own shafts…I always figured it was an art or skill that I didn’t have to be able to end up with good, useable arrow shafts. I admire you guys who are successful at it! Nice thread.

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

I have made a lot of arrow shafts in the past, I made a router shaft machine but couldn't get good stock for shafts. I could get 13 shafts out of a clear tight ring doug fir board from Lowe's but my spines would be all over the place from that board.

Some of my best shafting was from 3/8" poplar dowels hand selected from Lowe's. I would barrel taper them by hand and match the spine sanding by them while chucked up in my drill. A labor intensive process but the end result were fine tuned shafts that flew better than anything I could buy.

I find the statement that your time expenditure makes shafts too expensive and it is easier to just buy shafts to be the norm for younger folk who want instant gratification.

Us old folk grew up with a different mindset about learning to be self sufficient. Every thing you learn along the way is another notch in your belt to help you make it if things get really tough.

I eat a lot of full meals where nothing comes from the store, of course I could buy all the meat and vegetables but there is nothing as satisfying a producing your own and knowing that if there is a food shortage at the store there won't be one at the Krewson house.

For me the progression was at first buying everything archery related, them making my own bow strings, then buying arrow components and making my own arrows, then making my own shafting and collecting wild turkey feathers for fletching followed by making my own selfbows and now even my flintlock rifles.

I am winding down on making archery stuff now and have only made cane shaft arrows and turned a couple of 3/8" hickory ramrods down to good arrow shafting lately. I traded turkey feathers for hundreds of arrow shafts years ago so I retired my router shaft machine.

The old saying "time you enjoy wasting isn't wasted time" applies to me.

|

|

| From: CStyles

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

Took them out this morning for the first time. Shot my string follow Howard Hill Big Five, 55@27. As a number of replies have mentioned, pretty satisfying when they erknreally well. I also get a kick out of the idea the board was just $7, I know it is not about the money, but somehow I really like that. Gotta love those chartreuse feathers from Sagittarius, really easy too see. Here are two shots from 15 yards. Chuck S

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

Eric, I've made several MZ ramrods for my 29" .54 green mountain ball barrel, from my old hickory arrows. Point taper both ends of the shaft. Grind the point off 160 grain 11/32 target points. Drill and tap for screw on jags. I grind a concavity in both ends for centering on the ball when loading. That way I don't have to do an endo with the ramrod after ramming the load, or find which end is tapped. Having a couple extra cleaning and wiping sticks is mighty handy when shooting at the bench or truck tailgate, which is frequently the case with me.

|

|

| From: CStyles

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

Regarding the Dowel maker are you guys using the $214 kit or the $60 stand alone dowel and tenon maker. The also sell some arrow specific parts. Links below https://www.leevalley.com/en-us/shop/tools/hand-tools/dowel-and- tenon-cutters/42331-veritas-dowel-maker

https://www.leevalley.com/en-us/shop/tools/hand-tools/dowel-and- tenon-cutters/52401-veritas-dowel-and-tenon-cutters

https://www.leevalley.com/en-us/shop/tools/hand-tools/dowel-and- tenon-cutters/60496-veritas-dowel-inserts-for-arrow-makers

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

God, for unknown reasons, desired to make all things. No surprise that some of us would rather make things than buy them. 8-)

It also brings us pleasure to look at what we have made and say, it is very good.

There is less connection to things we only buy.

|

|

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

$215. I got mine in 2004 from Lee Valley. It was ~$160 shipped with 3/8ths insert.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

If you shoot heavier spines up into the 80+ range, def go with the 23/64ths. I dial in the tool so the diameter is at the upper end of the spine I want, and spin sand down to spine.

|

|

|

|

| From: CStyles

|

|

|

|

|

|

|

| Date: 15-Apr-22 |

|

Bob thanks for the info Chuck S

|

|

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 11-May-22 |

|

I have made thousands of them since about 1970 I mostly make footed arrows and now exclusively use recycled wood.You get the best old growth well seasoned wood that way.Nails and screws pose a big hazard sawing blanks but metal detectors take care of that.I can machine shafts but I prefere to plane shafts but hand .My only matching is sawing blanks and spin sanding shafts.Well worth learning but needs dedication. Osr

|

|

| From: bradsmith2010santafe

|

|

|

|

|

|

|

| Date: 11-May-22 |

|

I have made some, ,but not alot,, I really appreciate the ones that do,, its lot of work,,

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 13-May-22 |

|

I have made so many shafts since I was kid I am now on my second blade with my record 9 1/2 block plane.Took 40 years to ware it out.Planed up a few shafts today and must be getting old cause to true the blank and round it off takes me about 3 1/2 minutes.I remember years ago I timed myself and 2 minutes or less would have been the norm.Slowing down but still loving it.One secret to great stable shafts is to cut blanks 1/2" square true up two sides to where the shaft will naturally sit straight .Then reduce the remaining sides to 3/8 square This will stress relieve the wood and the shaft will remain straight.i only knock off the corners to an octagon and spin sand the shaft to 11/32 or 5/16.I can round shafts off so good as to only have to hand sand them but it doesn't make the shaft better.Love planing Tungstan vanadium blades are the best there is .All you Stanley plane lovers throw out Stanley blades and use record replacements Done that with most of my Stanley,'s Osr

|

|

| From: pondscum2

|

|

|

|

|

|

|

| Date: 16-May-22 |

|

make all of mine pretty much like OP does. cut 1/2 inch squares, turn them into 1/2 inch rounds, then turn down to 3/8 inch & sand beyond 3/8...i stared at a picture of a Veritas dowel jig until i understood it and then built my own. a lot simpler than i expected it to be...

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 17-May-22 |

|

Just as an historical note, according to James Duff, old time fletchers considered it heretical to round arrow stock by slicing across the grain, the way a Veritas tool does. They held that cutting with the grain, as a plane does was better.

A router does cut with the grain.

I don't think it makes a significant difference, if the tools are sharp. Might be a factor with brashy woods such as Douglas fir.

|

|

| From: Shootalot

|

|

|

|

|

|

|

| Date: 17-May-22 |

|

I used to make quite a few and still make some occasionally. I like the poplar also. I live in a kinda dry climate and the local walnut has good stiffness and medium weight and I really like making arrows out of it. Of course, walnut would be pretty expensive to buy and might be to weak for shafts depending on where it was grown. Hickory is bullet proof and doesn't stay straight sometimes but makes a good heavy shaft. I bought a dowel jig for a wood lathe from a wood working supply store years ago and my machinist nephew made it where it would make four different sizes. Works pretty well.

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 17-May-22 |

|

James Duff's book can be read on archery library on line.I started making footed arrows when I was ten after seeing an old popular machanics book describing how to do it.I have made thousands af arrows since then .James Duff's books is about 90 percent of what I do.I like how his favourite shaft material is Baltic pine and Douglas fir he thought was wasn't bad either.His thoughts on salvaged wood is exactly what I have done for years.Best well seasoned old growth wood there is these days.You got to realise the period in which he wrote his book and routers and Dowell cutting jigs are OK these days. Although I can and have used routers and Dowell cutting jigs I choose not to .I do use a saw to cut blanks and I do spin sand shafts but all my foots and preliminary shaft shaping is done with hand tools.I have just made about 60 odd shafts , some footed and some not all recycled Douglass fir and Baltic pine .It has become an adoption for me but lots of fun. Cheers Osr.

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 17-May-22 |

|

Spell check ( should say obsession) not adoption Osr

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 17-May-22 |

|

Spell check ( should say obsession) not adoption Osr

|

|

| From: Shootalot

|

|

|

|

|

|

|

| Date: 17-May-22 |

|

I have Duff's book and it has helped me a lot.

|

|

| From: txdm

|

|

|

|

|

|

|

| Date: 18-May-22 |

|

I've made quite a few arrows from yapon and possumhaw shoots. They work, but I find it extremely hard to get two that shoot alike.

But I make board bows and have lots of hickory and white-oak cutoffs that I plan to run through the bandsaw eventually. Maybe they'll be more consistent.

|

|

| From: Batman

|

|

|

|

|

|

|

| Date: 18-May-22 |

|

This is fascinating! Since I am a total klutz with hands and tools, I admire and APPLAUD those who can do these things! GOOD HUNTING and BLESSED BE!

|

|

| From: jk

|

|

|

|

|

|

|

| Date: 18-May-22 |

|

Big salute to all of you!

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 27-May-22 |

|

Getting close to 100 shafts now .I just do a few each day.Because of spine and weight considerations I need to make shafts in the hundreds .I usually can weigh and spine a few matched dozen.I am lucky to have lots of various poundages in bows.Because I make so many shafts I can guess spine by just bending shafts in my hand and am fairly close to my spine meter reading.Baltic pine is my number 1 choice on shaft wood .POC don't come close but is quite good It just breaks too easily for my liking.They are equal to Baltic pine when footed though.i would love to try spruce some time.I have to start using other wood for footings rather than Australian silky oak .Similar look to snake wood .I have honduras mahogany New Guinea rose wood and Merbu.I am also splicing on ebony knocks with this batch .I don't buy any wood just use recycled wood .My ebony comes from piano keys.Shafts come from architraves ,old doors ,roof rafters floor boards and old furniture.Nevér any shortage . Osr

|

|

| From: 30pt buck

|

|

|

|

|

|

|

| Date: 27-May-22 |

|

I’ve got one of the original Brads Shaft Shooters. It’s 20 years old or more but have made thousands of shafts from all types of wood. It will make 5/16” , 11/32” , 23/64”

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|