| From: Gun

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

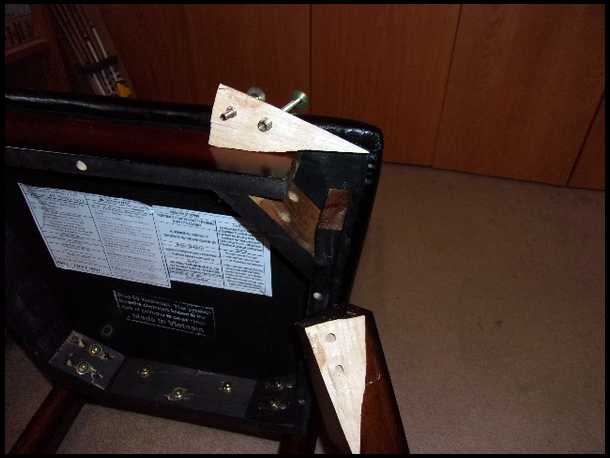

Well I recently I posted a ad for a pair of Bear limbs. (I had bought a few years ago from someone here but only shot a few times)

Had a reply soon after asking for more pix, which I sent. Then he wanted more of the locating bushings as he heard there could be cracks from install.

When I looked there were cracks in both limbs. I told him and deleted the ad.

I sent an email to Bear about the problem. Their reply was to send a copy of the original purchase if within the last year and they would replace.

So I guess I have some costly key fob material.

I had never heard about this problem before but as a retired machinist I can see how that can happen by untrained employees.

Just putting this out there for other buyers as something else to be aware of. Bummer

|

|

| From: Orion

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

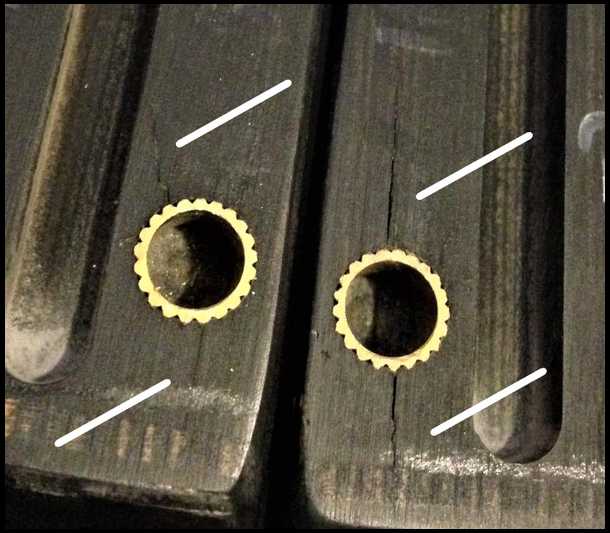

Does that mean cracks in the glass surrounding the hole that fits over the riser screw heads/bushings? I've handled a lot of Bear TD limbs and have never seen that, though the newer limbs are lined with a brass bushing. Don't know if the brass liner/bushing would cause splits in the glass, or if they are there to keep it from happening?

|

|

| From: Orion

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

I should add that the alignment holes on the Bear limbs that I own are at least 3/8-inch in from the base of the limb, i.e., they're 3/8 oinches away from the belly limb glass. I don't see how they could cause the limb glass to crack. A pix would be nice.

|

|

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

Not a big deal being in the bottoms of the limb butts.

|

|

| From: Gun

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

This the worse of the two. Over a inch long from what I can tell. The other is just shy on half inch.

|

|

| From: Bud B.

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

That is not a problem that I can see. Fill it with a wicking glue like Loctite 420.

That IS a problem with Bear drilling too small a hole for the brass bushing.

|

|

| From: Bugle up

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

Wow, never seen that before.

|

|

| From: 4nolz@work

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

If Bear will replace it let them.Someone was too rough without lining things up

|

|

| From: MStyles

|

|

|

|

|

|

|

| Date: 15-Jan-22 |

|

What Bud B said.

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

Bud B x2

|

|

| From: bowhunt

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

Yaa saturate it with wicking glue.Get it all the way down and filled up and you should have no no problem.

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

I agree with the wicking glue like Loctite. That limb butt area is really just a base an has no working effect.

|

|

| From: Nrthernrebel05

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

IMHO of another retired machinist, I agree it was caused by the bushing installation. I also agree with the loctite 420

|

|

| From: 4nolz@work

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

I have the bushings on many of my limbs they haven't changed.The locator pin may have changed it's just a screw.I was told years ago by an employee it was to keep people from putting the limbs on top/bottom reversed and they are unnecessary.Ive removed them on mine to stop the "tic" at almost full draw.The cracks are likely from forcing them.

|

|

| From: smokin joe

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

Bud B is correct. Fill the crack with locktite and use them.

|

|

| From: 4nolz@work

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

It's unfortunate as far as ever selling them

|

|

| From: Orion

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

That is rare. I've never seen it before. I agree that a wicking glue, or thin epoxy, would keep it from spreading. Did they come from the factory that way? Just as likely to be handled inappropriately after the fact as a faulty installed bushing, IMO. Aso possible that a tight fit simply opened the crack through shooting. Of course, that shouldn't happen, either. Rare, indeed.

|

|

| From: Dan In MI

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

Just throwing this out there. Why not pull the bushings, glue it, and shoot?

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

Looks to me like the hole's too small for the bushing. If that happened on the line at Bear, the foreman need to go to that bushing install station and knock the straight brimmed ball cap off the workers head. "Hey, yo, no more rap music at work." haha

|

|

| From: grizzley21

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

stuff happens, if made with wood, no, chair not made by bear,,,,

|

|

| From: goldentrout_one

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

Does anyone know of this crack at the bushing later evolving into limb failure? Or is the crack self-limiting and never goes beyond what was shown in the photo?

|

|

| From: Gun

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

Bob-LOL I've trained kids like that. Even threatened by one about taking me outside but backed down when I said lets go, stating you probably have that "old man strength".

Jerry- Can't be that rare as the guy that wanted them asked for pix of those location holes specifically as he had heard of others.

Mike- Yeah that's what I think too. I'm hesitant to even sell them in case someone gets hurt.

I don't need them anymore. A friend gave me a used pair of 60# limbs free since I bought these. I doubt I'll ever be able to use that weight again w my current shoulder issues. (and now still a 6-12 month wait for surgery after my friday consult). Yay Canada!

As I stated one is more than twice as long as the other. I will try the loctite just to seal it up. I've also had someone else interested in buying them.

It's just sad that a company as long as Bear has been around thinks more about profit than quality. It's mostly simple stuff that quality control and engineers should be on top of.

Thanks for the response guys, Its how we learn.

Still a die hard Bear TD fan.

|

|

| From: Smokey

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

What draw weight are they? Guess I better go start breaking down some Bear TD’s and check the limbs……..:)

|

|

| From: Gun

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

58# on B riser

|

|

| From: Smokey

|

|

|

|

|

|

|

| Date: 16-Jan-22 |

|

Gun,the heavyweight may have something to do with it? Don’t know but I guess it could be possible…..if they were 45# on A I’d take them off your hands and repair them….:-)

|

|

| From: Zepnut

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Couldn't you loctite them and have the weight reduced?

|

|

| From: fn

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Just wondering if the bushing is hitting the screw head when the bow is strung? The limb fit to risers can be a little from one to another.

|

|

| From: fn

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

My post should have said. A little different from one riser to another.

|

|

| From: hawkeye in PA

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

I've had a lot of Bear limbs and have never had that happen on multiple risers. Seems to me that would really have too be forced down on the locator head to cause I that. I have enlarged the hole a couple of times back in 'eighties.

As for the bushings coming out most are from the machine screw being to long bottoming against the wood. I have seen them spin out from over tightening but very little wood damage.

|

|

| From: Recurve Crafter ™

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

They probably cracked because the wedge material in those limbs are made from Rutland Dymondwood.

Bear hasn't used that material in their TD for several years because the Rutland plant burned down back in about 2014.

Dymondwood is hard, brittle, and unforgiving, especially when you're trying to press bushings or pins in the edge grain.

It tends to split very easily, so you have to be careful and intentional when working with it.

Personally, I don't think it was a good material choice for the Bear TD's design (whether it was for the riser or limb wedges).

The best material to use for Bear TD wedges is L or C grade phenolic, or resin impregnated Futurewood (which they are currently using). Those materials are durable, moisture resistant, and not prone to cracking like Dymondwood was.

Issues like this are frustrating when they happen, but I wouldn't expect any bow company to warranty a pair of limbs that are close to 10 years old.

Those limbs are probably fine for future use after they're treated with some Loctite 420.

I personally wouldn't have any reservations about using them after they're fixed.

If you're not planning on using them, just disclose that they are damaged (but likely repairable), and price them to sell "as is" with no guarantees against future breakage.

I'm sure someone would be interested in buying them as they are.

|

|

| From: Gun

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

I don't think these limbs are 10 years old. I've had them for 3 yrs. The previous owner said he only shot them a few times. I'm not going to put anymore $$ in them to have them reduced. Ordering the loctite and see after that. Thanks for the response guys. Good to hear from you Norm.

|

|

| From: hawkeye in PA

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Thanks for the information Brandon.

|

|

| From: Recurve Crafter ™

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

My bad Gun.

I was estimating the age of the limbs by when the material was no longer available on the market.

Based on the SN, it looks like they were probably made in 2017.

Bear must of had A LOT of Dymondwood in stock if they were still using it a few years after Rutland burned down.

|

|

| From: Kelly

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

October, 2017 and the 11th set of limbs that month so just slightly over 4 years old.

|

|

| From: 782GearUSMC

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Learn something new every day!

My 1970 Type II Bear TD with "Fascor" limbs (now hangs in a collector's gallery) and my 1972 "Mag" with "Fascor" limbs do not have brass inserts in the limb locators and not a sign of cracking at the locator hole.

I wonder if the screws on the newer Bear TD risers are not properly aligning with the locator hole in the limbs? If not, then there could be a torque issue with screw-to-hole alignment.

|

|

|

|

| From: Recurve Crafter ™

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

782GearUSMC,

The Grayling limbs used C grade (canvas) phenolic for the limb wedges, and those were tough and durable enough not to need any brass bushings in the pin holes.

I don't think they started using the bushings in the limbs until the mid 90's (when they were using regular actionwood in the risers and limb wedges).

During that time, they made a version of the Bear TD that was all brown actionwood (with no stripe) for a year or two, and then they offered a two tone gray and brown actionwood version for a few years (which was when they reintroduced the wooden A riser).

In my opinion, the bows from that era were some of the worst quality and least desirable.

I've had several and was not impressed with the quality any of them.

The limbs during that era were very wide at the tips and had very thick overlays.

And the risers from that era were the ones I preferred to use as donors for the limb sockets when I made a few of my own.

|

|

| From: babysaph

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

I wouldn't shoot that bow with a catchers mask and a football helmet on but that is just me

|

|

| From: Smokey

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

I can see three cracks around the brass bushing in the picture above all going towards the center cutout in the limb base.

|

|

| From: 782GearUSMC

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Curious so I looked up whether others have had same issues. Here is a good one.

|

|

| From: Gun

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Oh Crap Brandon! I just sent a No Stripe out to be refinished. I like it without a stripe. It has a small crack too at the bottom of the top latch. The limb w the longer crack is the bottom tho.

For a moment I wondered if that was because of more pressure on the top limb?

Bear did add a strength gusset to the top of the later versions of the B mag as those risers were breaking some w guys shooting heavy poundage.

Educational, even tho expensive.

|

|

| From: Smokey

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

The limbs would probably work just fine without those brass bushings even being made with the actionwood wedges,looks like between the bushings and the alignment screws there is to much pressure and I’ve noticed some of my new limbs not bottoming out in the riser pockets,so all the pressure when shooting is only on the bushings and screws!

|

|

| From: Recurve Crafter ™

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Well Gun, the good thing is, you can usually get the actionwood risers for a good price.

I've bought more than one in the $300 to $350 price range.

When the Bear TD's were originally offered, there was a very intentional reason why they were made with resin impregnated Futurewood.

The material is dimensionally stable (never shrinks or swells from moisture), and it's tough. It's very dense, and it's not brittle.

These were important requirements for the material to have in order to have minimal issues after the pocketed limb sockets were installed in the riser.

I was told this several years ago by Grant Young, who was told first hand by Owen Jeffery (who helped develop the bow).

Actionwood and Dymondwood will work, but it's not going to be as durable over the long term as Futurewood.

Bear got back on the right track a few years ago when they started making them again with Futurewood.

Even though you can still have occasional issues with Futurewood, it is the overall best material to use for the Bear TD.

|

|

| From: Smokey

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

If you removed the alignment screws the limbs would probably never crack at the bushings………maybe?

|

|

| From: Orion

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Gun: Thanks for posting the pix. Apparently not as rare as I thought.

Brandon: Is Futurewood just an impregnated/dyed maple. I have a coupe of sets of new white/black tips, and that's what the limb wedges look like to me -- black dyed maple, same as the riser?

|

|

|

|

| From: 782GearUSMC

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Here are my 1972 Bear limbs compared to later limbs with brass insert for limb alignment. Anyone notice something about the alignment CHANNEL on the earlier limbs vs. limbs made in 90's, to date?

|

|

| From: 782GearUSMC

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Here is another example of older vs later limbs with brass alignment inserts, posted on Leatherwall by other person. What do you notice about the alignment channels?

|

|

| From: 4nolz@work

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

I've seen tubs of wedges at the factory I assume they are CNC now and not reliant on hand jigs

|

|

| From: Orion

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

At a quick glance, the only thing I can see different is their length. However, that shouldn't make any difference AS LONG AS THEY'RE LONG ENOUGH.

|

|

| From: Recurve Crafter ™

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Yep, the length of the slot is not real critical.

It just has to be long enough, and not so long that it cuts all the way through the belly glass...lol

The size and location of the pin hole is more critical and a little trickier to get just right.

I could be wrong, but I don't think Bear CNC's them.

I think they still use the same jigs and fixtures to make them that they've always used.

I used a combination of CNC and manual jigs to shape mine.

I had a pretty accurate and efficient set up when I was making them, but I got burned out on making them.

|

|

| From: Heat

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

Tell me about it. Mine are more than a year old. Lots of keychain material sitting here I think. That limb fit very loose, too thin. Rattled in the pocket even when strung without padding them with moleskin. Shooting one morning heard a rack and this is what I found.

|

|

| From: Kelly

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

My bad, did read the date wrong, the sideways limbs confused me in reading them upside down. It is Jan of 2017 so just 4 years old.

|

|

| From: Recurve Crafter ™

|

|

|

|

|

|

|

| Date: 17-Jan-22 |

|

That happened as a result of poor grain orietation.

Unfortunately, some of the people that make the bows at Bear, aren't necessarily bowyers.

|

|

| From: Gun

|

|

|

|

|

|

|

| Date: 18-Jan-22 |

|

REAL Bummer Nick!

I'm really surprised that Bear doesn't use CNC. Would save them so much time and effort and provide more consistency in their products. Especially the grips!

The 3 styles for the old Mag TDs would cover pretty much everyone.

|

|

| From: 782GearUSMC

|

|

|

|

|

|

|

| Date: 18-Jan-22 |

|

Considering that the alignment channel on early Bear TD limbs was routed up into the “belly glass” tends to indicate that when the risers were cast and tapped it was later discovered that the set hole in the limbs would not fully seat and properly align and seat on the set screw without cutting the alignment channel longer.

If this is true, and the seating screw and alignment rail in the riser pockets are of size and location as they have always been, couldn’t the shorter alignment channel cause even a minute misalignment of screw to limbs, thus torqueing the inserts just enough to eventually acerbate the problem?

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|