| From: The last savage

|

|

|

|

|

|

|

| Date: 18-Jan-21 |

|

For you guys that HAVE used a , im thinking a kitchen stove on low heat to kiln dry riser wood, what temps work and and lengths of time are needed? Im guessing that its dependent on wood moisture content and size. And what is an ideal moisture number to build risers with? Thx for any input.

|

|

| From: BigJim

|

|

|

|

|

|

|

| Date: 18-Jan-21 |

|

| BigJim is a Stickbow.com Sponsor - Website |

If you have wood that can take it... few and far between, 212 deg and above will boil the water out in short order, like a couple of days depending on density and original MC. You will get cracking, twisting, and warping!

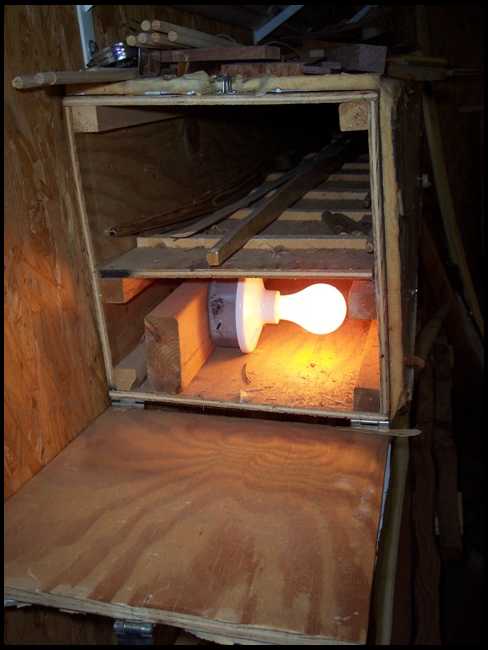

120 deg to about 160 will dry it out much more slowly and safely. Look up light bulb kiln. Weeks to months.

Also, any wood with too high of MC put in to "kiln" will suffer losses.

Some woods are absolutely not kiln friendly. The harder the wood, the less likely you can expedite the drying.

One way that I expedite the drying of difficult woods is to boil it. yep, I said boil it. This is labor intensive and when we start, we generally have enough wood to go for nearly a week and be done. Boiling still requires air dry times, but it is more like 1/3 the time it takes without.

My best solution is to buy 10 years worth of each species I use and then as I use it, continue to replace it. It will dry slowly, but on it's own schedule.

Drying is a science or can be. i read threads about problem woods and riser failures/cracks and nearly all of this can be attributed to wood that is not dry. Moisture meters can't be trusted completely and some, not at all. A background history of the wood is the most helpful along with a quality adjustable moisture meter with no less then 20 different settings and a table to adjust for your wood density.

I only wish I knew as much as I though I did, and long for information on who I could grill to find out the rest. BigJim

|

|

| From: Bowbaker

|

|

|

|

|

|

|

| Date: 18-Jan-21 |

|

I have been told to use very low heat 100 degrees or so and lots of air movement. Haven't tried it yet so no personal experience.

|

|

| From: BigJim

|

|

|

|

|

|

|

| Date: 18-Jan-21 |

|

| BigJim is a Stickbow.com Sponsor - Website |

You must be very careful about airflow.. again, with certain woods, it is no problem.

Even when not under heat, airflow can be the enemy to certain woods. It takes away the vapors fromn around the wood in subject faster and allows for subsequent vapors to take it's place. If allowed to continue in such fashion, the wood will dry too fast and crack.

Again, some woods, not a problem. other woods, big problem.

bigjim

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 18-Jan-21 |

|

Not sure about the wood kiln angle but they work well for curing takedown recurve limbs

|

|

| From: Chairman

|

|

|

|

|

|

|

| Date: 18-Jan-21 |

|

Some woods like cherry that ar very stable when dry can be a nightmare to get dry. I have seen much ruined lumber from a fan blowing over it to speed things along, sunlight also. I would contend drying and seasoning lumber is as technical as working the wood. What Big Jim said about boiling the wood is interesting. I do a lot of steam bending in my work. The wood is usually quite green but after steam bending it dries very fast without checking or twisting. I suppose that the bound water in the wood cells is driven out by the steaming. Have a small kiln heated by lightbulbs for finish drying small pieces, even with 40 years worth of experience tragedy strikes sometimes.

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 18-Jan-21 |

|

The woodworking program at the community college I attended had a kiln. The school would salvage trees cut in the community especially the Oaks. Once the kiln process was completed then the boards were stacked cross wise and those cement gizmos used in parking lots put on top to help keep the wood from warping. Being CA , not much rain, it wasn’t covered.

|

|

| From: Aeronut

|

|

|

|

|

|

|

| Date: 18-Jan-21 |

|

I stabilize punky wood with Cactus Juice resin and you need an oven to cure the resin. My latest project was spalted Elm and I used a makeshift oven made from an 8" diameter double wall stove pipe and two 100 watt light bulbs. I adjusted the heat with a light dimmer switch. Worked like a charm.

I have made several kilns or ovens out of materials such as styrofoam insulation for projects that required lower temperatures up to fire brick enclosures that needed higher temperatures. All were heated with a light bulb or heat lamp.

|

|

| From: KDdog

|

|

|

|

|

|

|

| Date: 19-Jan-21 |

|

Hi all. Great thread. I sure would like to know more about the properties of exotic woods myself. Can you professional bowyers go into depth about curing or stabilizing some of this lumber? Especially rosewood and ebony? Is it worth it to try and get a canister/pump for stabilization? Or boiling it? Curing it? I guess with the lumber that I have purchased, I am assuming that it is already kiln dried. And counting on trusting the smooth-on, and a 36 grit sand through the drum to "get a grip" on any riser laminations. ( flairs and crescents).

|

|

| From: The last savage

|

|

|

|

|

|

|

| Date: 19-Jan-21 |

|

Thx for the input gents, BigJim, do you have an percentage number that you try to reach through dying? Or is that number vastly different in different wood speices?? Thx

|

|

| From: BigJim

|

|

|

|

|

|

|

| Date: 19-Jan-21 |

|

| BigJim is a Stickbow.com Sponsor - Website |

Generally, i'm looking for 10% or lower. Actual numbers vary for your environment. Yes, if you are applying outside forces to dry, you can get it down to low and undesirable numbers, but if you put that in storage on the shelf, it will hit an equilibrium that reflects it's environment.

One big thing to remember... most moisture meters measure less than 1/4" deep and only between the pins. Most pinless only measure surface. The reading that matters is in the core. If you can make a cut to that and then read it, it will give you an accurate measurement.. or at least mostly accurate.

I have a moisture meter that is pinless and measures a space of about 3/4" x 2 1/2" deep and 3/4" deep. It has around 80 different density settings. The density settings are super important. With this meter, I can get an educated guess. They run between $400 and $500. BigJim

|

|

| From: JamesV

|

|

|

|

|

|

|

| Date: 19-Jan-21 |

|

I once had a turning blank that was dripping wet. Put it in the freezer overnight, next morning it had frosted over. Scraped the frost off and let it sit on the table a few hours and it beame dripping wet in a puddle of water. Dried it off and back into the freezer. Same thing but less water each time. After playing with it for about a week, I put in the wife's oven on the lowest heat for 4 days. It had lost almost a 1/4 of it weight and seemed dry. I was just playing around and never used it for anything.

James

|

|

| From: BigJim

|

|

|

|

|

|

|

| Date: 19-Jan-21 |

|

| BigJim is a Stickbow.com Sponsor - Website |

One way to determine how dry your wood is... store it in a dry enviroment. Preferably in a paper bag or a bag made of tyvek. Weight the bag and write the weight on it.

After a reasonable amount of time, weigh it again and mark the weight on the bag. Weigh it every week until it no longer loses weight for 4 weeks in a row... presto, equilibrium!... or buy your wood from me :)

bigJim

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 20-Jan-21 |

|

I don't use this much anymore because all my wood has been cut at least ten years. I may give a hickory stave a trip through it if I am planning to use it in a current bow.

I was once a serious duck decoy carver and used a variety of methods to cure my blocks even a microwave.

My old drying box has a rheostat on it so I can start at a low temp and work my way up.

|

|

|

|

| From: kokosing

|

|

|

|

|

|

|

| Date: 20-Jan-21 |

|

I know a self bow builder that put his staves in a car during the hot summer days. He didn't say the length of time.

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 20-Jan-21 |

|

Hot cars and hot attics are a bad idea for seasoning wood, I ruined a bunch of wood before I wised up.

|

|

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 21-Jan-21 |

|

Paul Comstock in his book The Bent Stick mentioned drying wood in his cat.

|

|

| From: 30pt buck

|

|

|

|

|

|

|

| Date: 21-Jan-21 |

|

Here us mine i made a few years ago. I can dry lams or blocks to 3' long or a couple hundred lams at a time. 2 -100 watt bulbs and 2 -4" inline exhaust fans facing in on each end. Lights can operate seperately from fans and lights can be switched on / off seperatly. Runs at around 90*. I run during the day and turn off at night to let wood acclimate. I generally lose 2-3% mc a day. Generally about a 2-3 week process. I have had little cracking. I end coat with anchor seal. I use stickers and wieght lams down with perforated wall board and old lifting wieghts. The lights have tubes over them to prevent hot spots.

|

|

|

|

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|