| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Ventured out with bow saw in search of hhb. Found some in the exact area my target buck inhabits, and went to work on it. Its not the best on I've seen but the one I wanted last year is off limits now, they posted the land. So I started cutting a 6" specimen. (I cut into a bigger one first and sap started bleeding out like blood from a sliced animal limb). It was too thick, 9 inches and the saw blade didnt like it. So the smaller one was cutting and most of the way through when the bolt holding the blade popped off and flng itself afar. There was an old broken barb wire fence right there so I improvised. I broke off a piece of the wire, strung it,through the bolt hole and restrung the blade. It worked! Cut the rest of the way but the tree would not fall. I looked up and branches were intertwined with another tree. I picked up a limb and batter rammed the trunk of the hhb off the stump and the tree dropped but did not fall over. I picked it up and slid it about 8 feet and the tree fell over. I cut the top off, about 8 feet section to carry out. Must have weighed about 60 or 70 pounds I figure. Started off and half mile later through swamp and dog hair, had it by the roadside. Walked the half mile down the road to the truck, loaded Trapper in and came for the tree. Got it home and proceeded to begin debarking. It comes off pretty good. Leaves were just starting on it and the bark is wet, but not dripping sap like the first one. Got about 1 third debarked in an hours time. My question for you (Chris??? R U reading this?) is What to you seal the ends with? Thanks.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Ventured out with bow saw in search of hhb. Found some in the exact area my target buck inhabits, and went to work on it. Its not the best on I've seen but the one I wanted last year is off limits now, they posted the land. So I started cutting a 6" specimen. (I cut into a bigger one first and sap started bleeding out like blood from a sliced animal limb). It was too thick, 9 inches and the saw blade didnt like it. So the smaller one was cutting and most of the way through when the bolt holding the blade popped off and flng itself afar. There was an old broken barb wire fence right there so I improvised. I broke off a piece of the wire, strung it,through the bolt hole and restrung the blade. It worked! Cut the rest of the way but the tree would not fall. I looked up and branches were intertwined with another tree. I picked up a limb and batter rammed the trunk of the hhb off the stump and the tree dropped but did not fall over. I picked it up and slid it about 8 feet and the tree fell over. I cut the top off, about 8 feet section to carry out. Must have weighed about 60 or 70 pounds I figure. Started off and half mile later through swamp and dog hair, had it by the roadside. Walked the half mile down the road to the truck, loaded Trapper in and came for the tree. Got it home and proceeded to begin debarking. It comes off pretty good. Leaves were just starting on it and the bark is wet, but not dripping sap like the first one. Got about 1 third debarked in an hours time. My question for you (Chris??? R U reading this?) is What to you seal the ends with? Thanks.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Ventured out with bow saw in search of hhb. Found some in the exact area my target buck inhabits, and went to work on it. Its not the best on I've seen but the one I wanted last year is off limits now, they posted the land. So I started cutting a 6" specimen. (I cut into a bigger one first and sap started bleeding out like blood from a sliced animal limb). It was too thick, 9 inches and the saw blade didnt like it. So the smaller one was cutting and most of the way through when the bolt holding the blade popped off and flng itself afar. There was an old broken barb wire fence right there so I improvised. I broke off a piece of the wire, strung it,through the bolt hole and restrung the blade. It worked! Cut the rest of the way but the tree would not fall. I looked up and branches were intertwined with another tree. I picked up a limb and batter rammed the trunk of the hhb off the stump and the tree dropped but did not fall over. I picked it up and slid it about 8 feet and the tree fell over. I cut the top off, about 8 feet section to carry out. Must have weighed about 60 or 70 pounds I figure. Started off and half mile later through swamp and dog hair, had it by the roadside. Walked the half mile down the road to the truck, loaded Trapper in and came for the tree. Got it home and proceeded to begin debarking. It comes off pretty good. Leaves were just starting on it and the bark is wet, but not dripping sap like the first one. Got about 1 third debarked in an hours time. My question for you (Chris??? R U reading this?) is What to you seal the ends with? Thanks.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Ventured out with bow saw in search of hhb. Found some in the exact area my target buck inhabits, and went to work on it. Its not the best on I've seen but the one I wanted last year is off limits now, they posted the land. So I started cutting a 6" specimen. (I cut into a bigger one first and sap started bleeding out like blood from a sliced animal limb). It was too thick, 9 inches and the saw blade didnt like it. So the smaller one was cutting and most of the way through when the bolt holding the blade popped off and flng itself afar. There was an old broken barb wire fence right there so I improvised. I broke off a piece of the wire, strung it,through the bolt hole and restrung the blade. It worked! Cut the rest of the way but the tree would not fall. I looked up and branches were intertwined with another tree. I picked up a limb and batter rammed the trunk of the hhb off the stump and the tree dropped but did not fall over. I picked it up and slid it about 8 feet and the tree fell over. I cut the top off, about 8 feet section to carry out. Must have weighed about 60 or 70 pounds I figure. Started off and half mile later through swamp and dog hair, had it by the roadside. Walked the half mile down the road to the truck, loaded Trapper in and came for the tree. Got it home and proceeded to begin debarking. It comes off pretty good. Leaves were just starting on it and the bark is wet, but not dripping sap like the first one. Got about 1 third debarked in an hours time. My question for you (Chris??? R U reading this?) is What to you seal the ends with? Thanks.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Sorry about that. Didnt realize text was still there. The tree has a very slight bent to it. Does that factor in to chosing which part to cut the stave from when I do? Should I use the bend as part of the 'bow'? Thanks.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Its not 6" either, more like 4-5"

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Aha! You finally did it!

Calvin, I seal the ends and backs with two coats of shellac, it dries very fast, but others use polyurethane, paint, glue, wax, etc with good results too.

Right away, today, right now, I'd try to 'read the tree' to find the best stave or two in it, cut the best part of it to about 6' long and seal the ends. Then I'd cut or split into staves and seal their backs, where you peeled the bark off, to keep that from checking as it dries. I would literally have done that stuff within minutes of peeling the bark off.

With it split or sawed apart, and the back and ends sealed, it's relatively safe like that for a while. You're no longer in a big rush. But I would soon reduce their width to about 2" end to end, and then remove some of the wood in the limb area so they're 3/4 to 1" thick, and put them in a cool area of ambient humidity, with no heat, a/c or air movement. Then they're REALLY safe.

|

|

| From: RC

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Seal the ends with elmer's carpenter glue, varnish, shellac, etc.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

You're a smart guy waiting until the sap came up. I didn't have that option when a guy gave me several HHB logs in the fall, so I spent weeks and weeks carefully removing bark with a drawknife and scraper. I didn't mind though. It's more work, but I like it.

|

|

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

What jeff said. HHB is terrible for getting drying checks. Seal it as soon as possible. Ends and back. I use to split it but now I do what Marc calls cerf and split. Cut with skill saw then split. Helps keep from tareing back. HHB is pretty good with a little run off. I've ruined to many just trying to split it. If you don't saw and split it soon it will split itself. Once it's in stave size pieces it's pretty safe but I'd give them another coat of sealer on back and ends. HHB makes a great bow Bjrogg

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

I cut, removed bark and cambium with power washer and cerf n split these 13 staves one Sunday afternoon. It is a good work out, but I've learned a trick or ten.

Bjrogg

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Great info guys. i thought I had to seal ends only and then wait to cut into staves for 3-6 mos. I have a table saw and a worm drive. Should be fun doing that eh? I wish I had a better piece. This one looks like it has a quarter twist. Will the sealer stick to wet wood? I put it,in the cool garage out of the sun so it wont dry out before I get to it later today. Would it help to cover it with a wet towel until I can get all the bark off? Kinda busy and have to work. Got a huge honeydo list also.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Gonna go find a couple more trees too. Want more options to work with. There are alot of them around.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Another question. Do you remove the shellac when you actually start making the bow later?

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Shellac will go on fine even if the wood is freshly cut.

No, don't bother with a wet towel. Just seal anything exposed where the bark is off with shellac. If you partially remove the bark from a stave and have to leave it for any length of time, even a matter of hours, seal what is exposed, and then you can pick up where you left off when you come back.

Allow the moisture to leave only through the cut and/or split sides.

Those look like some nice staves, Brian.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Trapper, yes, I remove the shellac with sandpaper or a scraper once the wood is dry enough to start the bow.

Just for your info... sometimes, some types of wood can be ok without sealing the back at this point. It depends on the type of tree, when it was cut, how much moisture is in it, how it's stored, etc. I've gotten away with it a few times, but I've ruined some trying to do that as well. It's not worth the risk to me anymore, so I just seal them all so I don't have to worry about it.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

By the way, you can't mess around too long getting the bark off. Eventually it will stick itself on there and you'll have to use a drawknife or something to do it.

Dang, you're making me itchy to go fetch some bow wood :^)

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Thanks Jeff. I trust your advice and will do that.

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Gentlemen, for those of us outside the U.S. What is HHB ?

PS really enjoying this already

|

|

| From: RC

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Great looking staves.

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Looking good, Calvin, glad you got out to harvest some. Jeff has you covered. I do exactly as he described.

Phil; HHB is Hop Hornbeam, its a beech.

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

HHB is just a little under hickory in hardness and specific gravity.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

I thought it, hop hornbeam, was an ironwood. Is ironwood a type of beech then? Incidentally, they call it that because there is a seed pod on it that looks exactly like beer hops. Same size, same color. Just doesn't smell as good.

Jeff, I got one coat of shellac on the exposed and partially debarked part (about half of the tree now) during lunch hour. The cambium was still moist and cool when I picked it up off the garage floor this afternoon. Got the coat on and now its laying on sawhorses waiting for me to do the second coat and debark the rest later today. I want to get every fiber of that brown bark part, the stringy part, off the back. I am just using a fairly sharp putty knife with rounded edges, and it seems to work great. So far I have not cut into the cambium layer. I am kind of a perfectionist so I am being pretty careful not to dig into it. Heard that is bad down the road.

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Thanks Jeff. They are some really nice staves.

If you have access to a power washer. Especially a hot water type one. It works great for removing bark and cambium even on winter harvested HHB. It leaves a perfect back and gets in every noock and cranny.

Trapperkayak you might want to finish getting these ready before you cut more. They take a lot longer to get prepared for curing than they do to cut down. It can get overwhelming if you've got to many to take care of at once. The fella I got these trees from said I could take more. I told him another day. This would be enough to keep me busy for awhile. It's all kinda time sensitive work. Hurry up and wait.

Bjrogg

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Guess I was typing while you were trapperkayak. The brown stringy stuff is the cambium. As it dries it'll get tighter and harder to remove. It usually will peel off with the bark pretty good during the growing season when sap is flowing. I've gotten under it and stripped it and the bark right off in long pieces. Reminds me I always wanted to do something with them.

Bjrogg

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Oh and ironwood is just a generic name for whatever type wood is the hardest in your area. Everyone calls it ironwood here to. I really have know idea what type wood it's related to. It does have buds just like beer hops though.

Bjrogg

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

OCR and PEARL DRUMS ... thank you

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Bjrogg, I looked it up, and it says it is related to the other hornbeam, which is also called ironwood and musclewood. And also called blue beech. I guess it is just its own kind of tree. And I guess the white part is just the sap wood then? Anyway, it does come off pretty easy. I don't have a pressure washer so I guess it will be elbow grease for now. I surprised myself and got half of it, the bark, removed, and just need to do the rest, and then really touch it up and finish coating it. Another tree will happen once the leaves come on more, since the bark will probably be even easier to peel then. Cutting it lengthwise will be interesting. I am enjoying the project so far. I might try to get two additional kid bows out of it, and one self bow. If my wife is interested, I'd make hers first. I think she just wants a Samick takedown though.

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Jeff..... what % moisture content would you suggest for working hhb

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Calvin, you said "So far I have not cut into the cambium layer."

I could be wrong, but it appears to me that you have most all of the cambium layer removed on the side that you've worked on. And that's good. The cambium comes off.

I apologize if you already know this, but for the sake of clarity, to be sure we're on the same page... and that you don't dig down into something you shouldn't(I think you're doing great so far).... see that bone-white colored stuff that you took it down to in a large area? It's very smooth and maybe even a bit slimy- wet when first exposed, the cambium is gone there. You're looking at the sapwood, and that surface will be the back of the bow. Don't even nick it. I think that's where you put the shellac, and that's good.

The thin fibrous, stringy layer between the inner bark and sapwood is the cambium. It looks pink-whitish in your pictures, but tends to turn brownish after it's exposed to the air for a while. 100% of it doesn't HAVE to come off, it won't hurt anything if islands of it remain, but I usually take it all off too, by the time the bow is done.

From the outside it goes... outer bark, inner bark, cambium, sapwood, heartwood. On hophornbeam, the outer bark, inner bark, and cambium layers together may not even be 1/8" thick. Most of the tree is sapwood. The heartwood seen in your picture showing the end cut is the brown core in the center, what? 1 1/2" or so in diameter?

Again, I apologize if you already knew this and maybe just used the wrong wording or whatever. I just didn't want you to inadvertently dig into the sapwood. You're doing great so far.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Thanks OCR. We have plenty of both around here. I made a stout walking stick out of a hornbeam, but I peeled it and didn't seal it and it checked heavily. I did it exactly the opposite of how it was supposed to be done (several years ago). I saw a hornbeam walking stick on Ebay for $90 a few minutes ago.. Wow! Nothing fancy either.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

I went out and dug through my HHB and actually found a couple I forgot to reduce. Oopie :^) Here's one with the bark still on and one that's reduced like I mentioned earlier in your thread. I used the drawknife and scraper to get the bark and most of the cambium off, but you can still see islands of the cambium still remain here and there. I'll get the rest of it off when I scrape and sand off the shellac.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Enough wood in the middle for handle and dips. Limb area about 3/4 thick at the dips, roughly tapering to 5/8 at the tips. Dries much faster that way.

|

|

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Nice. What about bends, what do you do with them initially? Nothing? Just let it dry and deal with it later? It might already be slightly bowed in the direction a bow is. Is that okay, or should I find a straight one? Thanks. TK

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

This is how most of my staves are quickly prepped for drying if I intend to make flatbow-selfbows with them... hhb, osage, hickory, locust, elm, etc. They're not all done that way, but most are.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Phil, I generally won't begin to further shape them until they're below 11-12%, and won't flex the limbs beyond floor tiller until they're below 8-9%.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Trapper, it's ok like that. That's part of what makes selfbows unique. However, the more odd shaped they are, the more difficult they are to make. For your first bow or two, it may benefit you to find the straightest tree you can. Or if one isn't readily available, spend a little time straightening this one.

If it's minor to moderate, it can be let go and either made the way it is, or corrected a bit later, when drier, with a heat gun. If it's moderate to severe(or needs numerous minor corrections), I like to correct it early(while green) with steam. Hophornbeam takes steam corrections well when green. My steam tube setup is simple and cheap and I can post a pic of it if you like.

|

|

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-Apr-19 |

|

Brad, it only looks that way because I'm just finishing up that new work bench and spent the last week or two cleaning the shop... you should have seen it two weeks ago, there was just a narrow boobytrapped path in to there. Honestly, it was getting quite dangerous and I had a few close calls. It's still only half clean though, but it's nice to have an open floor space. I'm about to do some SERIOUS spring cleanin.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

Jeff, that stave is Way straighter than mine is gonna be. It looks a little twisted too. I finished debarking it and coated it twice. Came out nice but i am not seeing 6 feet of smooth straight stave like the one in your vise. Next I am going to cut it. Yeah, please post a pick of your steamer. I am following your directions. I also dont have the tools. I will try to find a vise but they are not cheap. Need draw shave too. Ill make it somehow...improvise.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

Mine looks twisted, not yours.

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

Thanks Jeff....excellent workshop

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

Actually Trapper, I think I steamed that one and straightened it out. I tried to be as selective as I could that day. My buddy had loggers coming to cut oak trees and there was a good chance the hophornbeam would have been ruined so I cut several good trees, but still steamed some of the stave's from them for various reasons.

A little bit of twist isn't a big deal. In fact, look at that stave of mine with the bark still on it... it's twisted. It should have been corrected before now... must have gotten lost in the pile. Maybe I'll do that this weekend if I have time between my honey-dos and mommy-dos and post pics for ya of the steaming and bending.

Hophornbeam in general likes to grow twisted. Try to read the bark on the trees before you cut them. If you have plenty of it around, be very selective. If it's twisted, the bark will usually show it. If you avoid those with twist visible through the bark, you won't get in too much trouble, and any you bring home that might have a small amount of twist that snuck by ya can be dealt with.

If there's twist, you have two options. The best way is to layout the stave by following the grain, then hope you can straighten the twist with heat. That's what I usually do.

Or, you could layout a straight stave, violating the grain in the process, and hope it doesn't break later. Like Bjrogg said, hophornbeam can handle 'some' amount of grain violation. It's not ideal, and it's a judgement call. I have knowingly violated the grain on hophornbeam slightly by laying out a straight stave on a slightly twisted log. You have to cut it then, not split it... and sometimes as it dries it twists again and you have to correct it anyway :^/ You could use a bandsaw, or kerf it with a good circular saw. Snap a chalk line and cut an inch deep or more. Might have to make two passes. If using a circular saw be careful, keep the saw straight, and hang on tight in case it kicks back.

Yes, you're going to need a way to hold the wood securely.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

Hmm, I'm greener than the stave Im making. Once I cut the 1" kerf cuts, do I go another inch deep along the same cuts? Then roll the piece 90 degrees and cut along where the belly will be a the wide of the grip? Is a table saw an option?

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

I've found it best to first cut/split the log in half. So cut the first kerf, then spin it 180 degrees to cut the opposite side, ultimately, and in the best case scenario, with those two cuts in the same plane, or nearly so, sort of pointing at each other in the middle of the log. Plan your cuts around the best area to take a bow from.

Imagine cutting it cleanly in half with a bandsaw, that's the result you want, but with two cuts with a circular saw, first one side, then the opposite. Then if the cuts didn't meet in the middle, break it apart with a couple of wedges, cutting the stringers with a hatchet like Frank said. That 'splits it' in half.

Then, if each half is big enough to make two staves, you can kerf them down the center(this requires just a single kerf on half of a small tree) and split them too, resulting in four staves total.

If each half of the log isn't big enough to split again, then a stave will come out of approximately the center of each half of the log, resulting in two staves total.

Hope I'm describing it ok.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

Yes, I follow...I can picture all that you guys describe. The second option of two staves is probabl what I am looking at. Actually probably only one unless I want the second one to have a bunch of 'character'...LOL! I will only have a decent section out of the better log 'half' and maybe a kid bow or two from the rest. Just too many indentations and wows. Not many knots at all though. If furrows dont matter, I might get more than one stave. THis is the good side. Thanks gentlemen..

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

American Hornbeam goes by a lot of names including muscle wood, because of all the humps, and valleys on the outside of The tree trunk.Never been able to get my hands on HHB, but have built quiet a few American Horn Beam bows.Can take excessive set, but likes belly heat treat.Can make a nice bow if you work with it properly.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

We have a lot of musclewood around here. I would never have thought it would make a good selfbow with all the furrows. I bet they are interesting looking. They make stout walking sticks for sure.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

Calvin, I cut trees at my mom's after work so didn't get any shop work done, but I did take a few pictures of my steamer when I came home.

It's a standard ceramic coated camp coffee pot, sitting on a hot plate. The piping is just cheap 4" galvanized stove pipe. The 4" 'T' fits perfect into the top of the coffee pot, and the caps in the end have some 1/2" holes drilled in them to allow enough steam to escape to keep it moving along the full length of the stave. Filling the pot 3/4 full with water allows plenty of steam and time to bend anything I've put in there.

I throw an old wool army blanket over it to help retain the heat, but removed it before I took the pictures so you could see better how it was made.

Notice how the ends are little bit higher than the center, so the condensate water returns to the pot....

I also actually have a 2x4 cut to prop up and stabilize each end.

The common advice, which works, is to steam for about 1 hour per inch of thickness. I guess I steam a little longer because I let it go for an hour, or a hair more, for my 3/4" thick stave limbs.

|

|

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 24-Apr-19 |

|

Thats pretty ingenious invention Jeff. Is that your own idea? More ideas for retirement..;) Thanks for posting that.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

Not mine, but it is a good idea. Dean Torges described how to make it in his book Hunting The Osage Bow.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

Knowing me I'd burn the wool blanket on the hotplate and stink up the garage.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

I thought that too, so I folded it short and tied it around the pipe so it can't reach the burner.

Reminds me, I worked a double shift one night, went home and put an osage stave in the steamer... went in the house and sat down in a chair and fell asleep, must have been a few hours. Ran out to find the shop full of smoke. All the water boiled away and the bottom of the stave was burned to a crisp, charred, cracked deep, ruined. I'm lucky I didn't burn down my garage. Since then, whenever I'm doing stuff like that, I find something else to do right there in the shop so I can keep an eye on things.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

Wow, that sounds like something I'd do, just ask my wife!!! :)

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

Just me I guess.

But be careful using a circular saw on staves.

Growing up the son of a carpenter and woodworker and being on the wrong end of kickbacks on dimension lumber I won't use a circular saw on staves.

Jawge

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

Jawge, I have few options. Got any other suggestions..thank you. TK

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

If anything, I need to purchase a rip blade for it if I'm going to use it, not use a crosscut blade.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

Whenever I felt the need to kerf, I used a hatchet and 2 lb sledge and I would straddle the log and kerf with hatchet along the length. Sometimes it would wok and sometimes not as the wood would split along the grain anyway

These days I don't bother to kerf.

The stave does not look wide enough for two.

If It were mine I would just hatchet out a 3 inch stave., let it dry and make a bow.

With freshly cut wood, I have in the past reduced the stave to near bow dimensions, get the wood bending an inch or 2 and let it dry naturally or by other means.

I have moisture meter so I check often. HH I would like at 10%. If it it is above that I leave it alone and let it dry. When the belly wood gets to 10 % I continue.

I should mention that I don't own a bow grade bandsaw.

Anyway, that's what i have done in the past.

Jawge

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 25-Apr-19 |

|

Thanks, George, all this helps a lot. Because as the title suggests...

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

Got the stave cut and sealed with another coat. Cut it 7' so if I screw up I will have some extra to work with. It has a bit of a wow in it and cuttiin it was a trip, like digging the, tunnel from both ends, but I guess it came out okay. Hope I didnt get too deep into the riser area. Not it gets to dry in the basement. Looking forward to start shaping it this summer or fall. Pics follow. TK

|

|

|

|

|

|

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

Whoops... Ill cut,to the,chase, you've all,seen this,before anyway. Stave ...

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

The other end, now sealed and,ready to store. Its,bent alittle.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

Finished stave. Good day for a garage poject, its been snowing off and on like gangbusgers all day.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

Trappey's bored with me. Look says it all. He wants a,good,run, and this stick I got ain't somethung he can chew on or chase.

OCR, will try, need to get going on some household chores tho, how long can it wait,? A few days okay?

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

Yes, but remember... every second of every minute of every day, moisture is leaving. When it's wet, it works much much easier, especially if your primary tools are hand tools.

You got a good start.

I was out collecting wild edibles this morning and saw a few real nice elm trees with bows in them. Didn't have a saw so they were safe... for today.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

The other half is roughly a third or quarter. I might get a 6 year olds bow out of it. I have to get a draw shave before I can start working it down and shaping it by hand. I think Ill forego the electric tools for the most part, unless time runs short. I can imagine it would be a chore to work ironwood dry so I will definitely take you guys' advice. Looking forward to shaping something, gonna be kinda snakey I bet.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

Got both of those tools. Im hoping to get at least a 50-60# er out of the main stave. Sound doable?

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 27-Apr-19 |

|

Got both of those tools. Im hoping to get at least a 50-60# er out of the main stave. Sound doable?

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 28-Apr-19 |

|

I could probably work up to 75# but no reason to go that high, not taking it for cape buff I dont think... :) will try for 63# like,the rest of mine.

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 28-Apr-19 |

|

I agree. Try to get closer to bow dimensions. It'll really help with the drying process to. HHB is a bit more difficult to work with than Osage. Less forgiving and harder to shape and straighten with heat, but like already said it's a good bow wood and you can get a nice adult bow out of a sliver of wood. You got me started on some of my three year old HHB stash. Done straightening and putting recurves in. Need to let it reacclimatize before I start tillering.

Bjrogg

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 28-Apr-19 |

|

I also agree ferries rasp is on of the best tools for working HHB. I think it likes a toasted belly, but it doesn't make scrapping wood off any easier.lol

Bjrogg

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 28-Apr-19 |

|

Really enjoying this thread... thanks to all those who have contributed.

While you're all here, heat straightening and heat forming have beem mentioned in this thread...do you think that some woods respond better to moist heat( steam) while other wood respond better to dry heat (heat gun). Be interested in anyones opinions

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 28-Apr-19 |

|

This is going to be a steep learning curve for me. I have very little equipment to steam and shape with, or heat treat for that matter. Can a longbow style be made so I dont have to recurve it? I got a hatchet, rasp, and jigsaw... Lol! And knives and muscle.. Thats it! Maybe Ill try the slivers first! TK

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 11-Jul-19 |

|

Been reading this one also to help refresh myself as I have started back on my HHB. Got her bending pretty good, soon to be worked on my tillering station after I toast it.

Glad you are doing so well Trapper, with the help of these fine folks you will succeed.

|

|

| From: Ironfist

|

|

|

|

|

|

|

| Date: 12-Jul-19 |

|

All HHB bows I have built I have left the bark on until seasoned. I enjoy scraping it off with a draw knife reversed. I seal the ends with varnish and put away to season.The little ridges and valleys give some camo effect to the back of the bow. I also find HHB will bend with dry heat . I have never had a HHB bow break except for one kids bow tillered to 25 inches that was drawn by a 6 foot 3 inch guy. Good luck with the bows.

|

|

| From: Ironfist

|

|

|

|

|

|

|

| Date: 12-Jul-19 |

|

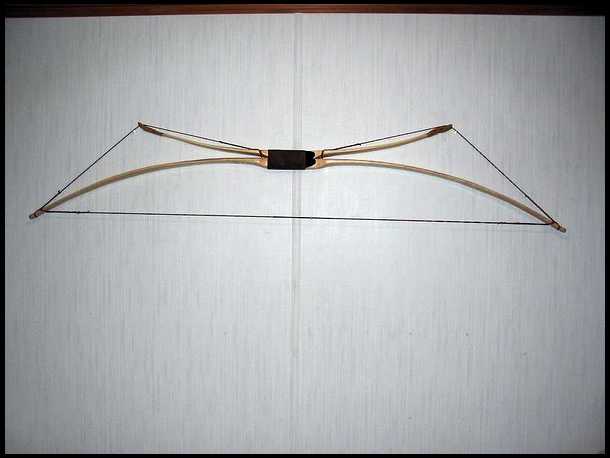

HHB is a great wood for building MikMaq warbows. Heres one that has shot thousands and thousands of arrows and still going strong.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|