| From: Bobmeister

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Let me start off with a little background . About a year or so ago +- I had a recurve bow I made in the classifides and got a PM inquiring about it. I immediately recognized his handle and thought this guy makes awesome selfbows. So I said hey do you want to trade for one of your selfies? and he said yes butt he would half to build one for me. well off went my recurve to Pearl and a few months later I get this gorgeous osage selfbow in the mail. What a great trade with a great guy and the bow isn't to shabby either :>)

Well fast forward a year later this summer and I get a message from Chris asking if I would want to do another trade. Heck yeah I will! but I need to wait until the snow flies to get some shop time. Anyway he asked about a 62" three piece curve and this is the build-a-long for it. Now the riser on this bow was glued up and blocked out rough from some bows I made last winter.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

The limbs will be Red Elm with Ebony diamondwood . Here is the material that I will cut the laminations from on the bandsaw.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Got the lams and wedges cut on the bandsaw and ready to grind to spec on the drum sander. These limbs will have a total .003" taper rate so I will use a .0015" taper sled to grind them.

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Because Pearl was a drummer he pairs those staves down with rhythm, and accuracy.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Smile.....

You got that right Bassman.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Here are all the parts before glue up. Chris wanted to now if I could stain the the limbs darker to go with the Ebony in the riser. I used gray/silver water based stain from Binghams to accomplish the task.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Forgot to mention that we will be running a strip of Stale-core down the center between the Elm core.

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Beautiful.

|

|

|

|

| From: Jim Keller

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

I love build a longs. Thanks

|

|

| From: crookedstix

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

That dark stain on the red elm is downright elegant!

|

|

| From: Bud B.

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Following!

|

|

| From: Nemah

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

What's Stale-core? RKK

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Sorry I ment Stabil-Kore.

|

|

| From: Pa Steve

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

This is going to be great. Red elm is one of my favorite veneers. Way under used imo. Thanks for taking us along Bobmeister.

|

|

| From: Dry Bones

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

Watching impatiently. :D

-Bones

|

|

| From: BATMAN

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

I'm with ^ DRY BOANES X2 ! BLESSED BE!

|

|

| From: Iwander

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

Amazing as usual Bob. The only additional improvement I can imagine is a "Bobcat" quiver. Steve

|

|

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

Got my popcorn, waiting patiently.....hurry up already. LOL. John

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

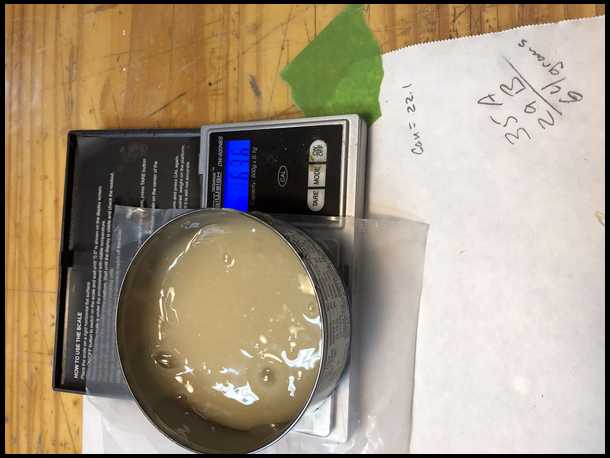

Preparing for glue up I weigh out the EA-40 to the proper amount on a scale. When I do a pair of limbs with these amount of laminations it requires 64 grams of bow-snot.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

When applying the glue I put down butcher paper with the glossy side face down (it has wax that can contaminate the gluing surface). You can see in the background one limb already in the form with zip-ties. The zip-ties will be pulled after partial air up.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

How come my pics are coming out sideways??????

Ok every thing looks good, aired up zips pulled and ready to put to bed in the hotbox for four hours at 175*.

In this particular form I can build a 60" one piece bow, LIF limbs ( medium or longs) or bolt down limbs as we are doing here.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Limbs are out of the form and ready to be cleaned up..

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Using the edge sander I will clean off the excess glue down to the wood and glass.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

After the boogers are cleaned off we need to check flatness . The cast iron cabinet saw top works perfect for this.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

The flattest side is selected and put down on the conveyor bed on the drum sander. I will proceed to grind from 1.75" wide down to 1.58" wide making sure that I flip them end to end and side to side every time I make a pass. This will ensure that they come out nice and parallel for layout and fitment.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Back to the edge sander to square up the butt end of the limb, I will take off about a 1/16" to clean it up.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Using the drill press and drilling jig I made we will drill the 5/16" limb bolt hole and the two 1/4" indexing holes. There are a lot better ways of doing this but I have just never gotten around to building the tooling for it.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

We've got holes, lets see how they bout up.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

We have dead nuts straight four point contact on the straight edge . I love when things come out square true and accurate :>)

No further fitting will be necessary, we can use centerline of the limb for profile layout and they will track straight.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Now we can cut the limbs to length. I have clamped the port-a-band saw in the vise and will trim the ends and then lay out the profile shape and cut it close to the but not on the layout line. Then sand to the line on the edge sander.

I use the port-a-band because it has a bi-metal blade and cuts fiberglass really well, also saving the blade on the 14" bandsaw witch are a lot more expensive.

|

|

| From: Benbow

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

What fun! That'll be a real looker! Ben

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

I just couldn't wait so I mounted them up and pulled it to 28" on the tiller blocks. 58.82# @ 28" keep in mind I sill haven't profiled them yet. Chris wanted between 48-52 so it will come down to around 51-52# when all is done.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Tips and overlays have been glued on and limbs rough profiled. So it's time to file in the sting groves. I will use a 5/32 chainsaw file and some abrasive cored to clean them up smooth.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Just realized we need a string for this thing. Here I'm putting together a 16 strand BCY-X two-tone (green and brown) endless loop and served with .025 Halo serving . Nocks should fit perfect with this combo .

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Got it braced , tiller looks great and the 59" string gives it a 7-5/8 brace height.

Pressing Onward and Forward to start shaping a bow out of all this square stuff we've glued together............

|

|

| From: chazz847

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Looks good!!

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Bob, that bow is amazing. I cant wait to get my hands on it and let some arrows fly. The dyed elm looks every bit as good as I had hoped. It will melt right into the side of a tree when I'm hunting with it. Im moving on your side of this swap as well. Got some great WDB skins from Mr. Yancy. Gotta have skins on wiggly osage limbs!

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

:>) I love wiggly ......

|

|

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Shaping the limb butts I bolt them down to this little jig thats the right angle then round the end to bend them in to the riser nicely .

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

After the limbs are shaped and sanded I will start shaping the riser. I layout a line on the back and start to take off every thing that I don't want with the edge sander, the off to the spindle sander and some other specialty tools. Then some file work and the 5" orbital palm sander starting with 100 grit then 220 grit.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Getting close , all sanded just need to do some fine tillering , put some arrows through it until I'm satisfied .

Next I will show how I stipple the grip....

|

|

| From: bodork

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

That's just one beautiful bow! Love the riser!!

|

|

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

That riser combo is a thing of beauty. Im going to be strutting around like a rooster with that jewel in my hand.

|

|

| From: LightPaw

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Amazing - Thanks for sharing!

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

First I draw out the exact shape I want then use a 1/16 round bitt in the dermal and make a trench all the way around.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Next I draw out some reference lines so I can develop a pattern and they keep me on track so the pattern will come out uniform .

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Then using a 3/32 round bitt I start filling in the field trying to stay parallel with the reference lines. Takes about 45 minutes to do a grip.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Then you get something like this when done.

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

GOOOOOD gravy Mr Davis!!!!!

|

|

| From: VJ

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Great job Bobmeister!!! really love the way you utilize one form to do multiple layups.. Your mosaic accents are super also... love to see a build along on those!!

|

|

| From: Jim Keller

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Man, that's a beautiful bow. Enjoy that one Pearl. Thanks for taking us along. Jim

|

|

| From: Rick 3

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

That is BEAUTIFUL!!!! Great Job!

|

|

| From: Pa Steve

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

No wonder Chris is excited. That bow is beautiful. Excellent craftsmanship. Thanks for taking us along.

|

|

| From: bodork

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

You sure you didn't take a Blacktail riser, sand the finish off, and then stippel it? Take that as a compliment because that riser is off the charts! Love it!!

|

|

| From: Dry Bones

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Amazing. Gotta love that look. Waiting to see the whole package together.

-Bones

|

|

| From: oldhunter1942

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

I have one of your recurves, great little bow.

|

|

| From: greyghost

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

Awesome looking bow

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

A work of art,very nice.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

Its had a lot of shop time at 6 yards but we need top take it for a test drive around the block.

20yds

Seems to like 30" FMJ 400 with 50gr inserts and 125gr point.

Riser is cut 1/8" past centerline so a stiff arrow works nice.

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

Let me give you a TIP don't eat the yellow snow.....

|

|

| From: Bobmeister

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

All done Chris its 51.4#@28

Merry Christmas to every and hope you enjoyed the ride.......................

|

|

| From: Draven

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

Great looking bow!

|

|

| From: bearfootin

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

WHAT. !!!! You gonna trade that thing.. Very nice job.

|

|

| From: Jim Keller

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

That’s about as pretty a riser as I’ve seen. And that grip looks perfect. Great job. Jim

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

You hit that out the park. That riser combo and dyed elm is a perfect pair. I have a bunch of .400 & .500 FMJs I can try. I may stick with woodies though. I just love the warmth of them.

You are putting the heat on my butt! I need to get yours done ASAP :)

|

|

| From: Huntdux

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

What a piece of art. Amazing!

|

|

| From: PECO

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

Very well done!

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

OH MY, Well done sir. John

|

|

| From: MStyles

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

Top craftsmanship, well done!

|

|

| From: ductape

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

That's just a down right beautiful bow. Excellent work Bobmeister!

|

|

| From: Supernaut

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

Beautiful bow and I really enjoyed the build along, thank you sir!

|

|

| From: Oldbowyer

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

Bow looks great Bobmeister

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 31-Dec-18 |

|

I received the bow a few days ago. It shoots every bit as good as it looks. Im a total wood arrow addict. I shot some FMJs and some 23/64 73# woodies. I'll stick with the wood for now. They are more quiet and every bit as accurate. The bow with the wood shafts is nearly as silent as a well tuned RD bow would be. Fabulous work Bob! Thanks again and again.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|