| From: RonG

|

|

|

|

|

|

|

| Date: 06-Dec-18 |

|

Fellas, I finally installed a dehumidifier in my wood shop, three days ago it was 85% humidity now it is holding at 40%. The building is drying out as I have been taking readings on the interior walls and they are down to 8% from 14%

I checked my iron wood bow and I got a reading of 5.8% then I couldn't get any more readings after that I'm sure the moisture content is too low for the meter. Should I raise the humidity in the shop or keep it low as possible. I did have it down to 32% before I set the humidifier limit to 40%.

I am worried that the stave may be too dry to continue work on it.

By the way my shop is shaping up, I can only do a little each day, but I'm getting there.

Thank you again fellas for your help.

|

|

| From: Weylin

|

|

|

|

|

|

|

| Date: 06-Dec-18 |

|

I'm not a big fan of moisture meters for bow making. I think they can be deceptive and give a false sense of the moisture. I think monitoring the RH in the room is better. The wood will equalize with the RH given enough time. I wouldn't worry too much about the ironwood (assuming you mean hop hornbeam) getting too dry. It's really strong in tension and can handle some pretty low MC.

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 06-Dec-18 |

|

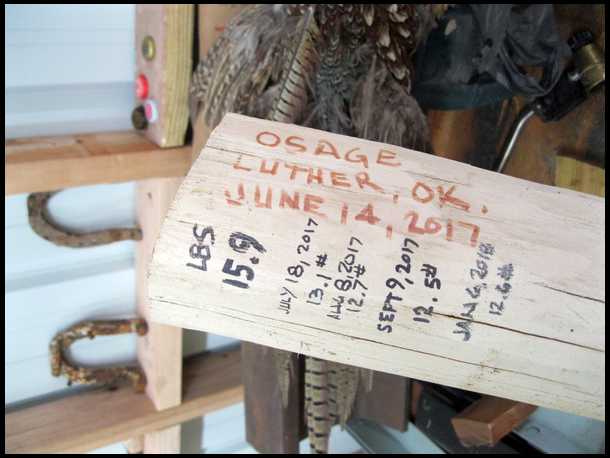

I prefer to cut, split, seal & weigh. When it stops losing weight, time to whittle. John

|

|

| From: Tlhbow

|

|

|

|

|

|

|

| Date: 06-Dec-18 |

|

I should try that one stoner. Still have enough to wait three years or more before cutting one out.

|

|

| From: Weylin

|

|

|

|

|

|

|

| Date: 06-Dec-18 |

|

I agree with the weighing method.

|

|

| From: Weylin

|

|

|

|

|

|

|

| Date: 06-Dec-18 |

|

I agree with the weighing method.

|

|

| From: Weylin

|

|

|

|

|

|

|

| Date: 06-Dec-18 |

|

I agree with the weighing method.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 07-Dec-18 |

|

Thank you gentlemen,

my room was pretty wet, but I am getting it down to where you can actually feel the difference, it was like walking into a sauna.

What I was wondering what should the wood measure in percentage of moisture or possibly what should I keep the room percentage at. I don't have a weight scale.

Yes this bow is a Hop Hornbeam and the next will be an Osage.

I was keeping the wood in a hot box at a low temp around 75 degrees and I couldn't measure any moisture at all with my meter., I would stick the meter in the wood on the wall and get an instant reading, but testing out the bow wood I couldn't get a reading except at the first moment. Probably the hot box was drying the moisture out of the wood near the surface and there wasn't enough to detect.

So I decided to get a Dehumidifier to control the room moisture thinking that would be the best way and let the wood balance itself out more naturally.

Plus all the equipment in my building was rusting badly.

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 07-Dec-18 |

|

I'm with Weylin on this one, moisture meters aren't for me. Get the RH under 50% for a few weeks and the wood will equalize, then have at it. Its all I have ever done and its never let me down.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 07-Dec-18 |

|

I use a moisture meter all the time from the time I start the bow to the first stringing. I have a pin type which only takes surface readings which is why I keep using it as I work the wood. I've been using one for probably 25 years.

I like 8-10% for everything but hickory.

For hickory I like 6-8%.

Controlling surroundings and using the hygrometer to measure relative humidity are fine too. Doesn't mean one can't use a moisture meter in conjunction with that.

Weighing is a good substitute because the wood will stabilize to surroundings anyway but you may be starting at a high percentage of moisture content depending on where you live.

I don't leave my bows in moist environments. I have 2 dehumidifiers going in my basement in the summer. Basement? What's that LOL?

Here in the Northeast winters are dry and summers are humid approaching FL humidity at least for a time. My bow for the year is in a heated environment for the winter and central AC for the summer.

Ron, that reading of 5.8% you got may be a surface reading. I've noticed that here in NH. MC may increase as you begin the process of bow making.

Anyway, I like my meter and don't see anything spurious (I've noted a a caveat above) about using it. Contractors around here use one all the time.

Jawge

|

|

| From: Bender

|

|

|

|

|

|

|

| Date: 07-Dec-18 |

|

Well alrighty then! :) I LIKE this! Yeah I have a meter. But somehow this just makes more sense.

More time consuming, but whatever.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 07-Dec-18 |

|

George, yes that is why I can't get a moisture reading on the surface because my meter is a pin type and I dried it in my hotbox, that is what I thought that is why I was wondering what the room should be kept at. If you attempted a basement here in florida you would have to feed the sharks and alligators.

Pearl, that is what I was wondering, I have the room at 45%, I can lower it, but don't want to get the wood too dry. My hickory failed because I built it in 85% humidity, it is holding 40 lbs. which will come in handy when I get as old as you guys....Ha!Ha!

I will hold it at 45% and check the surrounding walls and see what they stabilize to and I will carve on the stave and check it with my meter just to see.

Thank you guys for all the info, I can figure it out from here, if I carve on the stave in a couple weeks and it reads over 10% then I will lower the humidity and vice versa.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 07-Dec-18 |

|

Ron, that's why I keep using the meter right to stringing the bow.

Take wood from the belly. Check. If I get a reading greater than the ones I mentioned above then I stop and let it dry. Continue. Check again.

Of course, you should manipulate your work area/ storage. That doesn't mean you should not use your meter.

I mean...up to you. I'm just telling you what I've done for years.

Yes, I was joking about the basement in FL. LOL.

Jawge

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 07-Dec-18 |

|

I knew you were joking, yes, I will do as you stated, I have the meter I might as well use it also. Anyway if a person can double check their progress, it's the way to go.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

I have a pinless moisture meter I've been using since I started making bows 20 years ago. It works as intended and I trust it. That said, I don't use it much anymore because I don't often need to. If I get a stave from somewhere else I may test it so I know where to store it initially. If it's too wet, it may not come into the shop for a while, but my shop climate is controlled and once the wood is adequately reduced and spends some time there, I know it's good to go.

A bow wood storage area could be made too dry I suppose, and some staves are more prone to damage at those lower levels. I've over-dried two bows. They were completely tillered, shot a few times, then left in the drying box for a couple weeks(apparently the temperature was too high) until I could finish shooting them in... effectively done, only needing a finish. Yew is much easier to overdry than other bow woods... and will let go violently when it decides to tell you that you screwed up. Dang I miss that bow :^(

Between the dehumidifier, electric heater and a/c, they keep my shop at 45-50% RH. It keeps the tools from rusting and is the final drying place for my bow wood. Fresh split logs, or any other wood with high moisture content, begin their drying process in a safer area of the garage until they can handle the relative humidity of the shop.

Just weighing them until they quit losing weight doesn't tell you much if you don't know the relative humidity of the space and how it correlates with wood moisture content. Wood moisture will stabilize in higher humidity, stop losing weight, and still be too high.

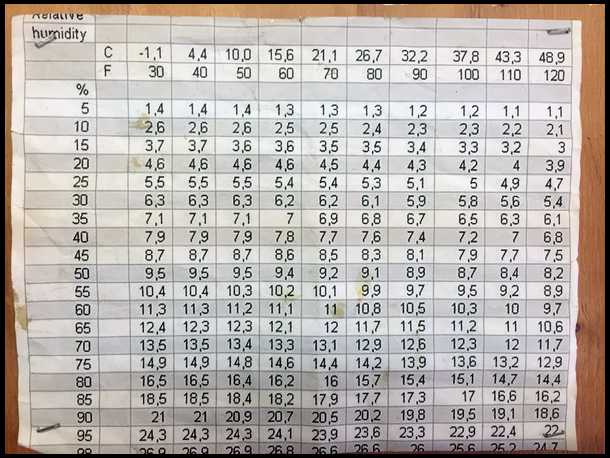

This chart is from The Bowyer's Bible Vol. 1, and might help, especially if using the weighing method

Relative Humidity - Moisture Content 30% rh - 6% mc 43% rh - 8% mc 55% rh - 10% mc 65% rh - 12% mc 75% rh - 14% mc

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

Well that didn't come out the way I wanted. lol. Let me try something else.

Relative Humidity - Moisture Content

30% rh - 6% mc

43% rh - 8% mc

55% rh - 10% mc

65% rh - 12% mc

75% rh - 14% mc

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

That is what I was hoping for Jeff, Thank you very much. I wish I didn't have the pin meter because it can only tell you what is on top of the wood.

As I mentioned I don't have a scale and don't really need to do it that way.

I am keeping my shop at 45% right now, so that sounds pretty good, I will check the wood after it has been in there for a few weeks and see what it says and adjust from there, regardless this is better than what I built my Hickory in. Maybe I can give my Hickory bow to the coast guard, it has already been water tested.....Ha!Ha!

I will make a copy of your humidity chart and post it in my shop, Thanks again Jeff.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

Ron, it doesn't matter that you have the pin type. Just keep checking as you work the stave into a bow. Eventually you'll get to within an inch of the back. That's what I do.

The only disadvantage is the cost but you already have one.

Jawge

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

Yes Jawge, but I was just saying if I thought about it at the time I would have got the other type, I'm sure none of them are dead accurate, but are great for comparison.

Yes I will continue to use the meter for reference, but I needed the specks that Jeff gave me.

I am checking the wood in the walls and it is down to 11% from 15% it will take some time to dry this building out. Thanks to you folks I have a base to work from.

When summer gets here and I turn on the A/C unit I'm sure I will have to do some slight adjustments.

I think it has been 9 days and I have dumped eight gallons of water from the unit, it has slowed down some showing the moisture in the building is reduced considerably.

|

|

| From: Tucker

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

Here is a chart you can use to estimate wood moisture content at equilibrium based upon the known temperature and relative humidity being consistent long enough for the wood to reach equilibrium. So by using the weighing method talked about above, when the weight stops changing the wood is at or very near equilibrium. You can then look at the chart to figure out wood moisture content. ( Just because wood reaches equilibrium and weight stops going down doesn’t mean that the moisture content is low enough to work into a good quality self bow. Some wood like birch and hickory NEED to be at a lower moisture content than others in order to avoid massive set.)

|

|

| From: Tucker

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

Jeff- the chart you shared above is good. It just left out a small yet important bit of information- that being what the temperature is. relative humidity alone will not dictate moisture content of wood at equilibrium. It is also a function of temperature. This is because air (and wood)have differing capacity to hold moisture based upon the ambient temperature. To illustrate this: saw mills preparing lumber use kilns (heat) to drive off moisture and reduce wood to a specific moisture content. If it were a function of relative humidity alone, it would be much less expensive for them to put wood in sealed buildings with just dehumidifiers running, at a specific relative humidity, with no regard for what the temperature is.

|

|

| From: Tucker

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

*Addendum to post above- I’ll concede that in most cases the Relative Humidity- Moisture Content chart that Jeff shared above Is “close enough “ for most purposes making wood bows. Depending on temperature there can be 2-3% difference in final wood moisture content. Most of the time this won’t be a problem, but if the wood is of a type like birch then it can make a big difference, since it seems that each kind of wood has its own m.c. in which it quits taking so much set when bent, and getting it below that threshold is important.

|

|

| From: Coop

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

Man I wonder how the Indians did it? Seriously makes a guy wonder how they did it without moisture meters and such. Lots of info here for sure. I'm just a dumb ol fiberglass lam guy and work with thin strips!

My buddy makes some awesome self bows and I'm amazed at the performance of them.

|

|

| From: MStyles

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

When I made my bend-thru-the-handle hickory selfbow, the moisture content in the stave got down to 6%. That took about a year before It got down from 11%. That bow is 60” #60 @ 28”.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

Thanks Tucker, as you further pointed out what Jeff sent me is close enough for a selfbow in most cases, but your chart will come in handy on those 90 to 100 degree days here.

As mentioned above my hickory was made in 80% moisture, it held its shape for a couple of hundred shots, but it bent back and took a set and I lost 12 pounds. I am working at not letting that happen again.

I hope others have read this and hope that it helps them also to make great self-bows.

Thank you everyone.

COOP, there is nothing wrong with lam bows, it takes knowledge and skill to make any bow. Self-bows are a little more picky you might say.

|

|

| From: Coop

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

My buddy always told me he takes a piece of wood and makes the bow out of it that the wood says here's your bow. Me as a lam bow guy takes a piece of wood and makes the bow out of it that I WANT to make.

Serious question. How did the Indians make bows without moisture meters or knowing the relative humidity? Enquiring minds would like to know.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

They used their senses. They could see when it was taking set early in the bending... that means let it dry some more. Feel it's strength and resilience, or lack of them, which is proportional to moisture content. Hear whether it rings like a bell when dry or offers a dull wet thud when tapped on solid ground or a rock. Keep it dry and warm by the fire. Use the fire to soften it and shape into reflex or align the limbs. Use flint to make axes, scrapers, antlers and bones for wedges to split logs. Simple. Use what ya have.

Same way they make them without fiberglass lams, epoxy, steel tools, electricity, and machinery to grind trees into perfectly flat and precisely tapered thin strips.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 08-Dec-18 |

|

Same way many still do it. We're trying to help folks develop those senses, help folks gain knowledge, skill, and experience. If that initially means using a hygrometer and scale, so be it.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 09-Dec-18 |

|

Jeff we have no solid ground or rocks in Florida so I have to use a hygrometer.....LOL!!

Thank you for your time, knowledge and expertise.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 10-Dec-18 |

|

The building is a solid 50% relative humidity and the dehumidifier is shutting off then coming back on when I open the door to come in, but doesn't need to run long. Now to wait a month and see how my wood staves are drying out.

Thanks everyone.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 10-Dec-18 |

|

Mine is off more than it runs this time of year. The heater kicks on too sometimes and that helps.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 11-Dec-18 |

|

(quote) The stomach cant wait 13 mo for seasoned bow wood in the fight for survival!

Good point Shawn....Ha!Ha!

Jeff, the dehumidifier actually puts out warm dry air, neat! I got one four times larger than what I needed, so it does the job very well.

Thanks for the inputs fellas

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 11-Dec-18 |

|

Some native tribes had a working bow ,and one in the works at all times seasoning it over their fire with smoke ,and heat.Others strung the bow reverse with a string.Then they would sinew back it,and let it dry naturally.Western Indians had dryer climate than east coast Indians. Still holds true today. Hickory is a great wood for making bows in low moisture climate. Not so much in high moisture climates.Tends to take on moisture, and takes set.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 11-Dec-18 |

|

Yep. Elm's interlocking grain is stubborn. I've used the antler splitting method with hickory, works great.

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 12-Dec-18 |

|

ocr ,trolling again

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 12-Dec-18 |

|

OK folks no fighting!!!!!...LOL!

I am no where near the expert you two fellas are, but didn't most of the native Americans back their bows with sinew and if that was the case they would probably have used Hickory as it is easier to work into a bow with primitive tools or maybe they just used what was available, I'm sure we are more selective of our wood than they were because we rely on the bare wood and they relied on the sinew.

I agree that Hickory is not the bow wood for Florida unless you build and keep it in a controlled atmosphere between use.

Not taking sides, this is just my observation from what I am reading. If I am wrong you can tell me, not a problem.

By the way I took another reading of the wood walls in my shop and the moisture is down to 9.2% and the relative humidity is 52%, now I am getting close too working wood again.

I have a Mohawk bow that is totally sewn up in leather of some type, you can't see what it is made of, I think it is more of a ceremonial bow instead of a hunting bow. I have had it for over twenty five years strung and hanging on the wall, not much poundage. I got it from a Mohawk native American, Joe Jr.

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 12-Dec-18 |

|

Yes , the Cherokee Sudbury bow was also a hickory bow.At nearly 66 inches long it has a lot of set.They made it work for them at 45lb. pull.I built the same bow with about the same amount of set. The bow would kill at 45 lbs for sure, but I have made sugar maple, walnut,birch,and white oak survival bows that shot as well or better. The eastern woodland Indians made longer bows ,because they were on foot.The plains Flathead, Souix, Apache,and many more made bows both d shaped ,and unbacked,and some sinew backed bows with reflex. Horse bows,so they were shorter.Some of the best bows ever made came from the California Indians, Yurok, Wintu, Hupa,Klamath, Modoc,and on and on.Most of ,but not all were wide,thin, short,reflexed sinew backed bows made from yew or juniper, or mountain Ash, and some other woods. There bows were beautifully painted,and there napped heads ,and arrows were works of art.Though they were all Indigenous people of North America their bows were diverse to say the least.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 12-Dec-18 |

|

I hope he had better luck with his....Ha!Ha!

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

very interesting thread ... I have a question if I may ..

What are the different characteristics between seasoned wood, and dried wood

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Byron Ferguson said it, ...Any bow will shoot a good arrow, but no bow will shoot a bad arrow. or something like that. In other words it's the arrow not the bow that has to be spot on.

Phil, I am not an expert, but kiln dried wood is done in a very short time span and is more expensive and possibly the wood could be a little weaker than seasoned wood.

Obviously seasoned wood is balanced pretty much through the whole stave and matches it's environment which makes a much better prospect for a bow if it is dry or wet enough.

I think there is not much difference except I think kiln dried is not dried all the way through because of the short time it is forced dried.

Maybe one of the experts will add to this.

I will take a picture of my Mohawk bow and post it after I get done with my honey do's this morning which are a lot more than normal....Ha!Ha!

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

... So is seasoning just the removal of moisture?

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Must be something to it. Never worked with a 5 or 10 year old stave.

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

I cant explain it, but can promise seasoned osage/yew is much better than dried. It works differently under tools, it reacts differently as the tillering process is being done and it holds it shape better in the end. Why? Beats me.

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Interesting.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Yes, what Patrick said.

Pearl Drums, it's just like smoking meat for 18 hours it is much more tender and tastes better than cooked for two hours.

That means us old guys are better than you younger ones, because we are aged.........Ha!Ha!

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

I have to agree with that, Pat. It has to be something at the molecular level. But, I'm just a simple guy building simple bows and cant scientifically prove any of it.

So Ron, you're saying you are smoked meat and I'm just cooked meat at 46 yrs old? :) :)

|

|

| From: Pa Steve

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

I worked one osage (seasoned) stave that was over 20 years old. It was hard as a rock and very rough on my hand tools. The composition of the wood was much different than a two or three year old (dry) stave. I don't have near as much experience as most here but the difference was night & day.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

That is a good one pearl Drums, but I didn't say that, I was just repeating that aged is better than not aged...Ha!Ha!

I guess that doesn't work the same with people.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

The first osage selfbow I made was from a small, 4" standing dead tree. It must have stood there and waited for me for many, many years. Knowing osage as I do now, I'd bet it was standing there dead before I was born. I've looked at, and worked a lot of osage, and never saw another piece like it.

It was the same color as the osage right there in HedgeHunter's picture. There was no characteristic bright yellow wood anywhere inside. Drawknife was sharp, but wouldn't cut into it. Not a single decent sized curl came off that s.o.b. and there's a lot of my dna in that bow, both sweat and blood.

Even fresh off the stump, 'green' if you will, it was like petrified wood, and I clearly remember thinking, 'screw this, if every bow is going to be this tough to make, I'm tapping out, I just won't make em'. That was twenty years ago, and to this day, by far the hardest battle I've ever fought with a piece of bow wood. Still have that bow.

Yep, dry and seasoned are different.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Seems that dry and seasoned are different but is one better? Don't know. I feel strongly both ways.

Whenever I've needed wood from logs in the past I would cut it, seal the ends, stave it, debark whitewoods, reduce to near bow dimensions, get the wood moving slightly and dry it. Make a bow.

I have a moisture meter and use it throughout the process.

Jawge

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

How about black locust? I found a log along side the road that was hollow in the middle, but good growth rings on the out side. I was able to get 4 nice bows from that log that I still have. The log was so heavy I split it in 4 pieces right were it laid to load it on my truck.That was a real gift.Does it act similar to Osage or not? Can,t remember if was hard to work with or not. I know it was some of the best wood I have ever had to make bows from.I sinew backed 2, and made 2 self bows.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 15-Dec-18 |

|

Yes, BL is a very good ow wood. Along with osage it can be made from standing dead trees. Some have even used old BL fence posts for bows. Jawge

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

Yes,is it a candidate for improving with seasoning? That was the question.Some times it is called the Osage of the east. High crown with a trapped back, and belly heat treated ,and slowly and carefully tillered seems to make a bow close to Osage when finished.Not as good in compression though.Never had Yew to try, but after Osage, Black locust, Elm, and Walnut are my favorite woods to make sinew backed, and self bows.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Hey Fellas!!!! A miracle happened, as you know my Hickory rawhide backed bow ( my first real attempt) came out to 52 lbs. when I finished it, unfortunately I built it in 14% humidity and lost 12 lbs after shooting it a few hundred times.

Fast forward to three weeks ago, I installed a dehumidifier in my wood shop. I am running a solid 52% relative humidity, which would be around 9% humidity, I am reading 8 to 10% in my walls.

The miracle is that I noticed my Hickory shooting a lot stronger and harder to string, I put it back on my tillering station and pulled it to 27.5 and got a reading of 45.2 lbs. I did it several more times and duplicated the reading within 2 tenths. I gained back 5 lbs.

I didn't think that was possible, but I saw it myself, I have been shooting this wet noodle for over a year and suddenly noticed the difference and checked it, sure enough 5 lbs and the bow is shooting a lot faster also.

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Good,now keep it in a controlled climate,and have fun shooting it. Last thing I do with a hickory bow is to heat it up very warm, and apply a mixture of linseed oil, turpentine, and bee,s wax to it.Then I hang them in my game room at 70 degrees year round.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

I have eight coats of tru-oil on the hickory, should I just use beeswax on it now?

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

I never used beeswax. I usually follow Tru Oil with 3 coats of spray on Spar Urethane at least on osage because it is a a good grain sealer. On whitewoods I skip the Tru Oil. No product will completely seal out moisture. Jawge

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Thank you Jawge, I will let the bow dry out for a few more weeks and follow up with the urethane. It may not do anything, but it couldn't hurt either.

OCR, I will keep that in mind for my HHB that is under construction.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

I hate to beat a dead horse, but I checked my Hickory bow with my pin meter and it is down to 8.1% moisture and my Yew is 5.2%

Goes to show that you can't seal the bow with tru-oil. The low moisture atmosphere is taking the moisture out of the wood right through the finish.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

HedgeHunter, I might try motor oil.............just kidding!!!!

I will keep that hickory bow around my house for target shooting.

I noticed my yew bow is not drawing up the moisture like the Hickory, they are hanging six inches apart, 3% difference in moisture content. I made that bow many years ago for bow fishing, it's been submerged in the water, thrown on the bank up against Cyprus knees, in other words through a lot, I even broke one of the limbs off trying to straighten it and glued and wrapped the limb and you can't see the break and it is working well. I took the line spool off a couple years ago and am using it for hunting.

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

That's why osage is king and ALWAYS will be. No better all-around bow wood growing on planet earth. You can have all the elm, hickory, hackberry and whatever else you want. When the poop hits the fan I'm grabbing osage every single time.

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

Will wrote that on the board a few years back didn't he?

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

OK fellas, I got it now and I also have two osage billets.

Thanks everyone.

I don't have to worry about drying out my yew the temps outside are in the forties with 86% humidity...Ha!Ha!

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

If anything, Ron? This thread was an interesting read for me :)

|

|

| From: Bassman

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

I bought a hickory board bow once from an Amish cabinet maker that had been in his shop for a while.The board was kiln dried.Moisture content when he checked was 14%.So yes Hickory can suck up a lot of moisture in a short period of time,but in a dry climate is a great bow wood.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

Thanks Pearl, I am fighting a losing battle with the moisture, but I have learned a lot from this thread and the input from all over the country. Now I have a better understanding of what I need to do to make a better bow from the start.

I am starting back on my almost finished bow with a great more knowledge of what I had.

My shop has stabilized at 9.1% moisture in the walls and benches, just right for bow making .........Yahooo!!!

I hate to ask all these questions, but I want to make the best possible bow that I can make, I guess I need to move to PA. or NY....Ha!Ha!

By the way, even though my Hickory took on a 2" set it still shoots great, thanks to you guys.

The most important thing is I hope someone else gets knowledge from my crazy questions.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

Yes Shawm, it is a smooth quiet bow and slings an arrow with authority, it ended up at 45lbs.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|