| From: blowgunner

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

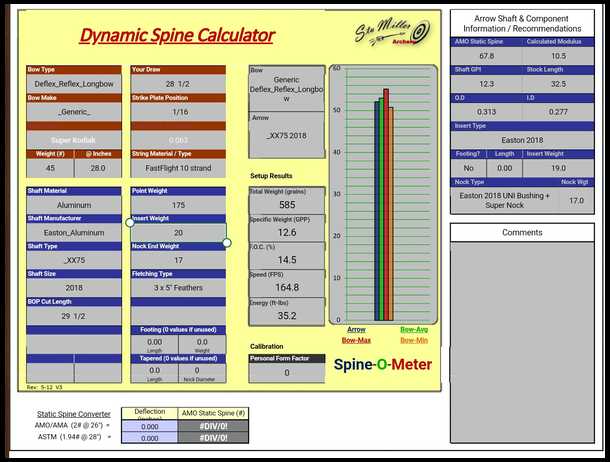

I'm wanting to start shooting aluminum arrows so I have been putting some numbers into a few spine calculators. The resluts I am getting are different than the suggestions I'm receiving from other traditional archers. See if my results look right .

|

|

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

I find Stu's calculator to be very accurate. I'm not going to try to analyze your results, but I will suggest that accurate inputs are essential so it can be beneficial to double check all static and dynamic measurements of the bow. Draw weight, degree of center shot especially.

|

|

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

What Mike (Longcruise) said. The more accurate the input, the more accurate the output.

Rick

|

|

| From: blowgunner

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

The bow is a Maddog Prarie Predator. 45@28" I pull to 28.5". The string is 10 strand d10 padded to 14 on the loops. The shelf is 1/16 left of center.

|

|

| From: Mpdh

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

When you say left of center, is the bow left handed, or is it right handed?

MP

|

|

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

So cut BEFORE center, like a dual-shelf ambidextrous...

JMO, those numbers look a lot like what I would have expected; I just don’t know that I would go nearly 50% over the 9 GPP which has served so many, so well, and for so long. I’d think you could easily go to 1816 for that set-up, depending on how long you like your arrows.

|

|

| From: blowgunner

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

This is the riser

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

Is your + 1/16" measurement counting the strike plate material?

If not, you will need to add the thickness of the material to your measurement, and you will be closer to + 1/8" most likely.

Rick

|

|

| From: blowgunner

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

It is not including that I will figure that in

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

Well, in any case, you’ve hit the jackpot getting Rick to help you with that one.

Anybody care to share a link to the online version?

|

|

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

In the above screen shot of the calculator, I added another 1/16" to the strike plate material thickness, which takes the arrow position to +3/16"

In all honesty, this would be where I would start at.

Just remember to always start out with your shafts cut longer than calculated (about an inch), then take them down a little at a time until you get them shooting how you want them to.

I'd bet good money on this calculation being very close (if not spot on) to what you wind up needing to work best for you.

Rick

|

|

| From: blowgunner

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

Awesome! Thanks Rick!

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

P.S.

That means you need a strike plate covering/material that is 1/8" thick.

You probably already figured that, but I wanted to be sure.

Rick

|

|

| From: blowgunner

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

Know of any 3/16 or 1/8 strike plates?

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

Cory, the fuzzy side of industrial velcro is 1/16" thick.

A standard toothpick is 1/16" in diameter.

Your bow is already +1/6", so add those two (piece of toothpick under the velcro covering), and your arrow position will be +3/16.

Rick

|

|

| From: Mpdh

|

|

|

|

|

|

|

| Date: 02-Dec-18 |

|

If your strike plate is less than 1/8 just put something behind it before you attach it to the bow. You could use layers of tape or a match stick. Get it to the thickness desired and glue onto the sight window.

MP

|

|

| From: Turkeyman

|

|

|

|

|

|

|

| Date: 03-Dec-18 |

|

Arrows by Kelly

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 03-Dec-18 |

|

Mike (Turkeyman), as near as I can figure, that chart is based on a point weight of around 120 - 125 grains.

Cory is using 175 grain points, so the chart don't even come close for him. If he wanted to reduce his point weight it would.

Rick

|

|

| From: Gray Goose Shaft

|

|

|

|

|

|

|

| Date: 03-Dec-18 |

|

For me, bare shaft testing lies between between the starting point of shaft selection and the goal of good arrow flight. ACS has a free PDF file about bare shaft tuning that is well organised. It is a confidence builder for me to tune an arrow and bow combination so I can shoot 20 yards without fletching. From there on, any bad shots with fletching are the fault of my form.

Google: ACS tuning longbows and recurves

Also, nice bow. I like the color combination, the slim design, and the handle portion.

|

|

| From: blowgunner

|

|

|

|

|

|

|

| Date: 03-Dec-18 |

|

Thanks it's Osage orange and walnut with maple trim. Im ordering some gamegetters here shortly and I will start tuning. I have been shooting beman centershot 500 and they fly perfect with a 29.5" arrow and 150 up front .

|

|

| From: Turkeyman

|

|

|

|

|

|

|

| Date: 03-Dec-18 |

|

Rick sorry buddy. I didn't realize the point weight.

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 03-Dec-18 |

|

[[[ "Rick sorry buddy. I didn't realize the point weight." ]]]

No problem Bro. I just wanted Cory to be aware of the difference.

Kelly's chart is pretty accurate as long as you know you need to work with around 125gr point weight.

Rick

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 03-Dec-18 |

|

Yup . A simple chart that provides one correct answer, but only one of many possibilities.

Like everything else, we can make this as simple or as complicated as we like ;)

|

|

| From: yorktown5

|

|

|

|

|

|

|

| Date: 03-Dec-18 |

|

I don't see a mention of what those "other archers" have recommended that would be so different from Stu's calculator, but I'll comment anyway.

Very many traditional archers are lousy at finding the ideal arrow...really lousy. But also vocal in delivering "what worked for me" bad advice.

I've gone so far as to opine that a lot of them are better shots than they believe themselves to be because they fail to use the best arrow specification.

Heck, feathers are there specifically to hide/overcome a bow-arrow mis-match. The perfectly tuned arrow, released perfectly hardly needs fletching.

There are so many interactive details to camo an off spine arrow...I might even suggest that "making sure your broadheads fly like your field points" can be translated as: "Your arrows are not tuned right with field points, but its disguised and takes the broadhead to make the wrong spine stand out."

Trust Stu. Trust Rick B. GF and Grey Goose too. Distrust the "just change your point weight" guys. As they suggest, if you don't get good flight from Stu's outcome, YOU did something wrong with your inputs. I'll add that something wrong with the inputs can be hard to find, but its there someplace.

Rick R.

|

|

| From: DT1963

|

|

|

|

|

|

|

| Date: 04-Dec-18 |

|

I am not tracking, why would anyone recommend to build up the strike plate 3/16 of an inch as opposed to selecting a stiffer shaft to begin with?

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 04-Dec-18 |

|

Actually only adding 1/8” to get to 3/16”... the bow is +1/16” to begin with...

And 1/8” really isn’t very much. It’s nice to have one small point of contact (directly above the pivot point) to minimize contact/drag and also to reduce the effects of torque.

Personally, I like to keep the strike plate material thin so that I CAN use a bit stiffer arrow. But it doesn’t really matter all that much what the answer is, so long as it is CORRECT.

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 04-Dec-18 |

|

[[[ "I am not tracking, why would anyone recommend to build up the strike plate 3/16 of an inch as opposed to selecting a stiffer shaft to begin with?" ]]]

Because he was asking about the 1916, and 2016 shafts specifically.

Rick

|

|

| From: DT1963

|

|

|

|

|

|

|

| Date: 04-Dec-18 |

|

Rick, so would you normally just start with a stiffer shaft as opposed to building up the sight window?

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 04-Dec-18 |

|

David, I have specific point weights, and a specific overall length I want my arrows to be.

That being the case, I just calculate those in with the draw weight, and center cut of the bow to find the shaft I need to work with.

Doing that almost always gets me into a very good tune, but I will tweak the tune (when needed) by adjusting strike plate thickness/position.

Provided I have the arrow where I want it to be, and have a reasonable spine, I would much rather chase the arrow with the bow, than to try to chase the bow with the arrow. Hope that makes sense.

Rick

|

|

| From: DT1963

|

|

|

|

|

|

|

| Date: 04-Dec-18 |

|

Yep makes sense that is kind of what I do. since I almost always stick to modern fiberglass limbs and same poundage, my arrows are pretty much the same now days from bow to bow and I tweak/fine tune with shelf material, brace height, etc. I would say 80% of my bow inventory now shoots the same exact arrows 35/55 goldtips and I just fine tune that arrow to the bow. Just wanted to make sure I was understanding the shelf build up as I usually just put a piece of leather as a touch point and slap some Velcro on it - sometimes I might add a piece or two of double sided carpet tape to really fine tune but that is almost always going beyond my current shooting ability :)

|

|

| From: deerhunt51

|

|

|

|

|

|

|

| Date: 04-Dec-18 |

|

2016 would be my recommendation as well.

|

|

| From: Gray Goose Shaft

|

|

|

|

|

|

|

| Date: 04-Dec-18 |

|

I still like that bow, I just want to pick it up and loose the arrow. I think it is the slim handle that gets me. Osage, walnut, and maple, nice.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|