| From: Jinkster

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

I ordered and received a dozen hard rock maple shafts from Kevin Forrester and they were spine/weight matched too perfection when they arrived.

I ordered 11/32 shafts that tapered down too 5/16ths at the nock end and this presented a bit of a problem with my Bearpaw Taper Tool as despite my best efforts of building up the shaft with painters tape to register the 11/32 taper tool collet?...once the taper tool blade grabbed hard rock maple?...the tapers came out all over the place...not off by far but still?..."Slightly Off Center"

For a minute there?...I was going to say screw it and just roll with it writing it off as "A Best Effort" (working with what I had) and painted them up...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

but at the end of the day?....I couldn't bring myself to glue nocks on what I knew were off center tapers and both my time and money and Mr. Forrester's efforts deserved better so this morning I took them too the shop and?...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

all tapers are concentric too all shafts with-in about +/-.001" :)

|

|

| From: AK Pathfinder

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

Thats some serious perfection right there. I wish I had a lathe to mill out such excellence on my woodies!

|

|

| From: David McLendon

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

Most people settle in life, only a few make the decision to really have things the way they want. Good choice, and I'd do that with all of them from now on.

|

|

| From: Orion

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

Good you found a solution. You might suggest to Kevin that he nock taper the shafts before he grinds the 8-9-inch taper from 11/32 to 5/16. That's the way most shaft suppliers do it.

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

Hand taper tools aren't really the best anyway for hardwood shafts. My friend hvac tech, who posts here now and then, made a taper tool out of aluminum blocks about twenty-five years ago to use with his drill press/sander. It will also make perfect nock tapers...about a hundred of them in half an hour or less. He can also taper the shafts from 11/32 to 5/16 on another set he made. His former handle was Mr. Perfect, and so are his tapers. Good job there Jinkster.

|

|

| From: Knifeguy

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

When I started reading this one I wondered if the "old machinist" in you was gonna roar his head and find a solution and I was right. Nicely done Jinks. Lance

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

If I had that available I wouldn't bother with a taper tool any more.Way to go. >>>----> Ken

|

|

| From: Pa Steve

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

My thoughts were the same as Lance. Figured a machinist would Figure out a solution.

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

Lathe, not a bad idea. Creative minds at work. Now if I had a machinist background I would be tempted to mill my own riser.

|

|

| From: SuperK

|

|

|

|

|

|

|

| Date: 02-Jun-18 |

|

WOW! Now that's what I call "getting 'er done".

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 03-Jun-18 |

|

I don't have the mechanical aptitude to do something like that...it amazes me.

|

|

| From: Ambleman

|

|

|

|

|

|

|

| Date: 03-Jun-18 |

|

Hey Bill, nice work there. I have been where you are and I think “who’ll know the difference?” Of course, the answer is “I will”. That’s the best testimony to your work. Maple is fickle for sure, but you did a great job trueing it up. Well done!

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 04-Jun-18 |

|

Success...ever look at a bunch of things that are so perfect you can't tell one from another no matter how long or hard you look?....cause all the nocks glued on cookie cutter straight...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 04-Jun-18 |

|

Spined 65#s and cut 28"s long while wearing 100gr glue-on points?...without feathers yet?...the entire dozen weighs between 606grs-617grs where both the low and high were flukes and the lions share weighed 611gsr-614grs.

Initially the bare shafts flew a touch weak and too the right and while I probably could've corrected this by simply lowering BH?...I instead opted to replace the Velcro side-plate with a bit thicker leather strike-plate and this played out nicely and had the bare shaft flying like it was on a wire shot after shot and at 13.5gpp making this 64"/45# R/D Hybrid the quietest shooting rig I've owned yet...I'm pleased. :)

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 10-Jun-18 |

|

First I have to say that I'm extremely impressed with the durability of these hard rock maple shafts as there's been many a time that "The One" shaft I've been using as "The Bare Shaft" has struck my bales at Speeds and angles that would've surely snapped lesser wood shaft materials in half at impact....but not these Hard Rock maples and not only that but?..."Still Straight!"

I shouldn't be surprised because even though I've had some folks tell me that maple shafting can be a little squirrely?...my experiences thus far are the opposite as I keep in mind that it was Kevin Forrester that made them and hard rock maple has been a premier choice for limb cores for quite some time now so it must be some rather stable stuff when properly processed.

Between Mr. Forrester hitting exactly 65# spine on all shafts and me lathe turning the nock tapers?...they seem to shoot as consistently as any hunting grade CF shafting I've ever owned and all arrows came out weighing 620gr +/-5grs.

500grs is the 28" shaft (Nock Ctr-BOP) while 100grs is the glue-on point and the remaining 20grs is nock and feathers which leaves me with 9%FOC and 13.8gpp off my 64"/45# Hawk R/D Hybrid Longbow for an extremely smooth and whisper quiet 155fps and I think they make a stunning couple....

|

|

|

|

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 10-Jun-18 |

|

They do indeed make a stunning set. >>>----> Ken

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 10-Jun-18 |

|

I have a head cold today but was very pleased that the rig shot where I looked when snapping off 5 from about 12yds...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 10-Jun-18 |

|

They are fletched 3X4" using Gateway Shield Cut LW (White Hens) and the last of some real barred turkey feathers I sourced through Jim Casto some time ago.

These are going to be some fun arrows for quite some time to come and if I ever chose to hunt wood shafting?...it would be hard rock maple.

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

This combo is shooting so well?...I decided to spend some cordovan and sealskin upgrading the shelf and strike-plate...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

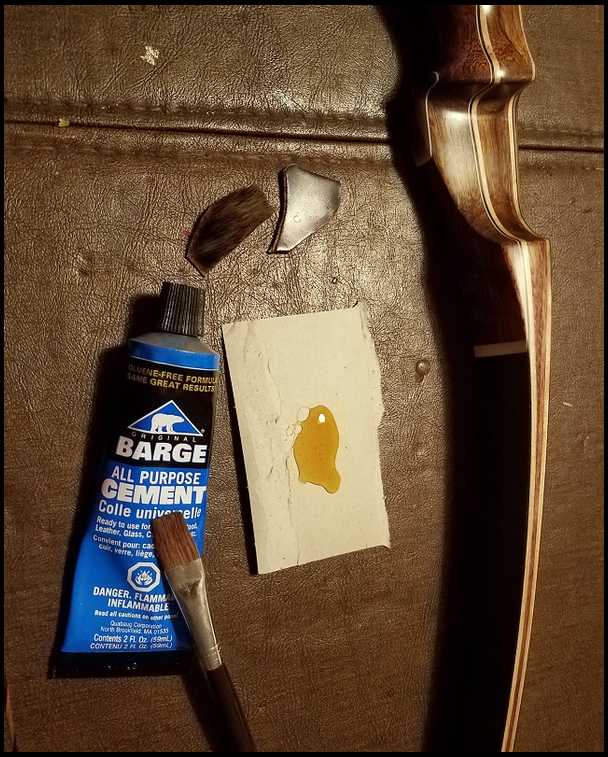

Mounting tape handled the cordovan strike-plate but I had to use Barge's on the oily sealskin shelf but came out pretty good...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

Despite being home sick today I braved 18yds with it earlier today when I had a little energy and thought moving around might do me some good and this is how my bales looked from there...arrows are in it and bow is on it...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

here like this...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

my maples nestle down into the sealskin real nice like...

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

and I was happy to see my bare shaft flying so clean that it had just as much penetration as the fletched...

|

|

| From: Jim Keller

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

Good job Bill. That is a good looking combo for sure. Jim

|

|

| From: RymanCat

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

Look better with goose feathers maybe.

|

|

| From: dean

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

My yelled that just the other day, "Close isn't good enough." She was not referring to arrows, she was in the bathroom when she said it. I wish I had the tools to do tapers like that.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

Nice Bill, best looking set up I've seen.

|

|

| From: Jinkster

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

Thanks folks and I gotta say that between Mr. Forrester's efforts matching spine and weight and getting those nock tapers spot-on?...these maples are shooting every bit as consistent as any hunting grade carbons I've owned as now I'm not just getting a taste but a huge bite of the passion that drives archers to stick with wood shafting.

I got bold tonight and started reaching out there looking for what point-on might be but with 28" arrows didn't find it in the confines of my backyard.

Walk back style the Bare Shaft was shot from 15yds while the fletched arrow nest too it was shot from 20yds and the one that's a few inches low/left was shot from 27yds...with very little change too the sight picture.

|

|

| From: Chad Orde

|

|

|

|

|

|

|

| Date: 11-Jun-18 |

|

That’s inspiring I need to order up some heavy spines and get back in the game. Thanks

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 12-Jun-18 |

|

Been using my own homemade power taper tools since the 1980's

|

|

| From: Fisher Cat

|

|

|

|

|

|

|

| Date: 12-Jun-18 |

|

Jinkster,

I have a Grizzly mini lathe (the longer version) at home. Not as cool or capable as the lathes I used to work with, but it's affordable and VERY handy for many gun and archery projects.

I have used it for cresting arrows, fitting & modifying points and inserts, and cutting carbon arrows to length. For arrow cutting, I made a holder for my dremel flex-shaft tool and use it with cut-off wheels ala toolpost grinder. It's very accurate since both the arrow and cut-off wheel are spinning and everything is controlled.

These little lathes can be a bit underwhelming compared to high end machines, but they sure come in handy and can produce some nice work if you understand machining and workarounds. Worth considering one... - John

|

|

| From: joe vt

|

|

|

|

|

|

|

| Date: 12-Jun-18 |

|

Very nice Jink, those arrows look awesome with that longbow! Great shooting.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|