| From: yohon

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

Just seeing if anyone has used Gary Renfro's "perfect taper" tool? Looks like a pretty slick set up and well made......

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

Got a link??

|

|

| From: yohon

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

https://www.youtube.com/watch?v=ny_BgnntTEg

http://traditionalarcheryproducts.com/product/the-perfect-taper/

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

Don't know how it could be better than a bench top sander and a jig.

|

|

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

So it’s a motorized pencil sharpener?

I think for that kind of money I would invest in something to taper nock ends, point ends, and shafts as well.

But it looks like it ought to work fine…

|

|

| From: Dale in Pa.

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

$110, You've gotta be kidding.

|

|

| From: Cameron Root

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

Yea well if you see the workmanship in the tool it's worth every penny. Quality costs and pays back in my book.

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

Tapering in a half second does nothing for me. Might be ideal for a pro arrowsmith who might want the speed and is willing to pay for it.

I'm gonna keep getting by with a TTV2.

|

|

| From: Cameron Root

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

Yes willing to pay for it but not for speed. The tolerance is tight so making sure you shafts fit the sleeve often requires a spin sand. This ensures accuracy in tapering. A sloppy fit makes a sloppy job.

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

Grabbed an arrow he used it on, twisted a field tip on tight...it did not spin straight. I would put mine up against anything out there.

|

|

| From: Cameron Root

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

B.s. your style has a longer rest making it more fool proof. If the shaft is straight and to spec on diameter the perfect taper tool is just that.

|

|

| From: Sawtooth (Original)

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Looks like it works pretty good. Overpriced? Not if you want it bad enough. I've seen people spend over a hundred dollars on CAMOFLAGED UNDERWEAR! So price is relative. If Connie had made the video I would give that product much more consideration after watching it over and over. :)

|

|

| From: longbeauxman

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Cameron, do you know if it will It stand up to Douglas Fir shafts?

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Np way I'd buy that design. Low speed peeling of wood that is naturally prone to splitting isn't a good design. Sometimes it works, sometimes it doesn't. The hand crank pencil sharpers in schools decades ago were very effective at making tapers at slow speed because they grind the taper, not slice it.

|

|

| From: flyguysc

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

I have a belt and disk sander from HF. Got it for $80.00 plus tax.Made a jig from info on you tube and can do points & nocks perfectly in about fifteen minutes(taking my time).

|

|

| From: hookman

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

I have one and it works great.

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

I put a 10 inch sanding disk in my table saw and use a jig. You can't get better tapers than that no matter what you use.

|

|

| From: Cameron Root

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Yes on df and Forrester hardwoods

|

|

| From: Cameron Root

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

It's high speed in an impact

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

When I make arrows I'm in production mode. I've made about 1K shafts using a Veritas doweling jig. It features two adjustable plane blades set tandem for a coarse cut and then a fine cut. With 2500 rpm HS drill and sharp blades it works great. When I start feeling increasing resistance feeding in the blank and see tear out on the shafts I know the blades need to be honed.

I used block planes at work all the time in the early to mid eighties. I haven't used one after I bought my first Makita portable planer. I don't like farting around when doing production is in order isn't for me. That effects how I view tool design.

|

|

| From: Greencb

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

I have one of the perfect taper tools and the woodchuck. If your shafts are true and POC the perfect taper does great.If I want to match a taper to a ferrule or I am using DF shafts I use the woodchuck. More often than not the perfect taper tool is my choice.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

I taper on a woodchuck. I straighten the shaft, chuck it in my drill and sand the point taper at high speed. When you are doing a few dozen at a time, spin sand tapering beats rolling those suckers by a mile. You do need straight shafts. You also need a refined technique and that comes from doing it. Probably four times faster then tediously hand rolling them on the 'chuck. No chance in hell I'd hand crank out five dozen points and nocks using a true taper.

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Hey, bob, I have the time to do that many but I'm rarely doing that many at a time. I also have a jig that will work on a sanding disc attached to a 10" table saw but it's a pain to set up. I also use it on a Rigid Oscillating sander but the belt wants to push the shaft out or pull it in depending on how it's set up.

|

|

| From: unhinged

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

That's a lot of money for a one function tool. I suppose if a person did not have the skill or desire to make a simple jig, it might be a good buy. I think I would go buy a disc sander and make a jig like Hal9000. I use a similar set up on a table saw. Guaranteed more accurate than the "perfect" tool.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

back in 2003 i took one look at that woodchuck and knew it was worth the money considering i always have an eye on production and hate working inefficiently. i also looked at the tru taper and immediately dismissed it as a design i,d get frustrated with. i,m glad it works for the dudes that own them.

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

I have the old taper tool they sold before TT changed the tool. It does Doug Fir as well as my WoodChuck. Only use WoodChuck for nock tapers now. I have gone to TopHat system for point end.

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

I also use mine to taper the ends of lams to glue them together (angle iron mounted on the right side) and use it to taper the ends of posts for string jigs.

|

|

| From: lawdy

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Juspassin just saved me some bucks. I have a table saw. Thanks for the tip.

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Is it possible to put a sanding disk on/into a circular saw?

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Yeah, I did that. The circular saw was a garage sale special that I rigged to a makeshift table. Worked great for a long time but eventually went up in smoke (literally) :-)

So, I did the sensible thing and borrowed one from my son in law!

|

|

| From: Dry Bones

|

|

|

|

|

|

|

| Date: 01-Feb-18 |

|

Sometimes I feel like I limit myself to what I have and what can be made. Threads like this one only prove that thought. Longcruise, does the son-in-law know or does he think it is on long borrow?

-BOnes

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

Well, I've had to loan it back to him twice in the last three years. :-). Then I bug him asking when hyis bringing his saw back.

He doesn't mind. An awful lot of the stuff I make is for his kids. LOL

|

|

| From: yohon

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

YEP....you guys saved me some $$....got a table saw that will be converted to a wood taper table saw LOL

|

|

| From: reddogge

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

I watched the video first and thought "That's a great product" but when I saw the price $110 I'll stick with my $10 taper block clamped to my disc sander. I don't do woodies much anymore anyway.

|

|

| From: yohon

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

Where/How do you guys measure to get the correct 5 and 11 degree line for the DIY taper with a table saw?

|

|

| From: unhinged

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

If you use a table saw to sand with, you should make a Zero clearance insert for the disc. I think you will get too much deflection at the dowel tip from the downward rotation of the sand disc, which will suck it into the gap between the table and the disc. Also do not use a disc like mine, it's insane and really dangerous, although it did make the perfect Zero clearance insert.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

Off topic.

The advantage of a Woodchuck vs the tablesaw grinder is:

1) Your tablesaw isn't useable through the tapering procedure.

2) The vee grove is built into the Woodchuck. It's close proximity to the sanding head means you can control the shaft where it really counts, right at the taper.

3) The Woodchuck motor can easily be tweaked for a perfectly tapered fit. Amazingly there is some minute variation between components.

4) Woodchuck features a built in adjustable stop that is easily adjustable in seconds for shift from point to nock tapers, or, adjusting just how pointy you want the end of your taper.

5) Most importantly for me, I can spin sand the tapers with my battery drill.

6) lastly, I don't enjoy making jigs for my saws, installing jigs on my saws, and genearlly farting around trying to make something that I can buy that makes the work faster, safer, and easier. No doubt I'm cheap by nature, but I have no problem spending money on tools. If you work with tools to make a living you'll know what I'm talking about.

As usual ymmv. That's my take on the Woodchuck.

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

Use a screw in adapter on the point end and if you have an older aluminum arrows that use glue on nocks... should get you in the ball park. Hold it up against the disk and mark the angle.

|

|

| From: yohon

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

DUH......thank Hal9000.....why didnt I think of that LOL!!!!!!

|

|

| From: Archergreg

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

If you are going to make a sanding disc for a table saw use a metal cutoff abrasive type blade. The picture above sends shivers down my spine.

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 02-Feb-18 |

|

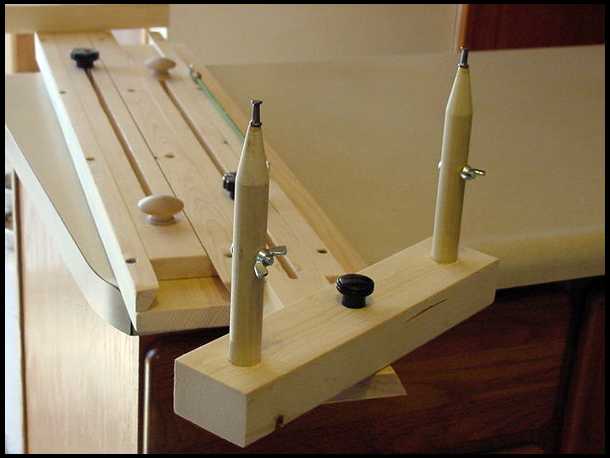

Here is my set up i built .there is a disk not shown

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|