| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

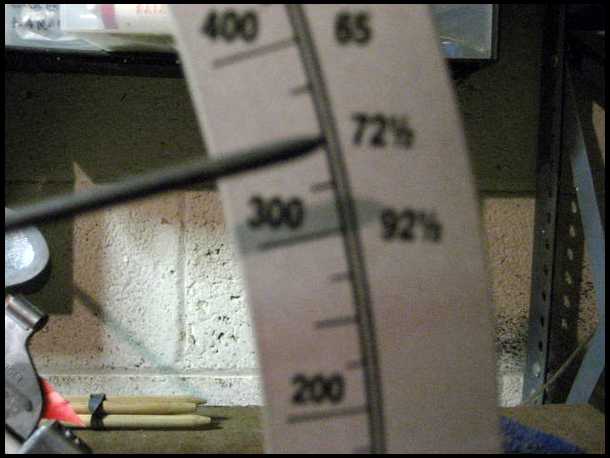

I have been using my Don Adams spine tester for several decades. It is a great arrow building tool, but I don't think I get the most out it. I recently spine tested and then dipped and fletched half a dozen 11/32 ash shafts. I have one arrow that does not shoot well and could not figure out why until I went back and spine tested it again. It spined 72 1/2 with the rift up and the nock perpendicular to the grain.

|

|

| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

Rift is up in this photo and perpendicular to nock as can be seen in previous photo.

|

|

|

|

| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

When I rotate the shaft 90 degrees the spine tester still reads 721/2.

|

|

| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

My question to the arrow building experts, is what is the acceptable difference when you rotate the shaft 90 degrees on the spine tester? The one bad arrow I made does not have the same spine when I rotate it 90 degrees. It is significantly lower than 72 1/2. In fact it doesn't measure the same when I rotate it another 90 degrees which would be with the original rift facing down. Thanks for any insight. I dislike making arrows that don't fly well. TLM

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

Wood arrows should be spined on the edge grain....the same way they are shot out of the bow!

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

I have heard of guys rotating the shaft to the correct spine

|

|

| From: tecum-tha

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

Exactly. Grain lines are 90 degrees to a bow when arrow is shot. This is supposed to be the stiffest possible axis of wood. On the spine tester the grain lines at the end should be vertical when you measure. That is the only way to measure a wood shaft right.

|

|

| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

"Exactly. Grain lines are 90 degrees to a bow when arrow is shot. This is supposed to be the stiffest possible axis of wood. On the spine tester the grain lines at the end should be vertical when you measure. That is the only way to measure a wood shaft right."

Looks like I have been measuring the spine wrong,

I did notice that there one bad shafts had different spine when rotated 90 degrees until back to the starting point. I assuming thats just a bad shaft. TLM

|

|

| From: Archergreg

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

I have had 2 arrows that if I rotated the arrow when nocked flew much better. It can happen.

|

|

| From: dean

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

Bought a batch of cheap cedars once. some of them had the flare going away on one side and towards the nock on the other. The worst shafts imaginable. That cross the shaft flare can either make an arrow very stiff in that segment or weaker. I upped the weight and reduced the spam by half just to compare to other straight grain shafts, to check for the span of variance. It is remarkable how unpredictable those bad flare arrows can be. They usually get to net short and get blunts, rabbit shoot aways.

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

I want all the experts to think about something. If the edge grain was the only way wood would have any strength, they'd have to re write all the books on building self bows.

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

The idea of grain and string groove alignment was as a time when self nocks were used exclusively. It was imperative to get the groove perpendicular with the grain to avoid split outs. With the advent of plastic nocks everything changed. The string cant split out grain it cant enter or get at. Feel free to rotate your shafts around until each matches one another, then mark it and place the glue on nock in the same spot. Don't worry, your arrows wont explode.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

My experience is like PD's as long as you are using glue on nocks. Don't try it with self nocks though obviously.

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Its part of the spine standard! In the hay day of wooden shaft the only ones that had spine testers were archery shops. Knowing that spine does vary a standard was established, so when you the consumer purchased a dozen shafts you knew where to place the nock and the edge grain was against the bow's strike plate. It was not aligned that way because for safety reasons because shafts with runout were not sold as arrow shafts they went into the fire.

Bob

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

And the more recently electronically mass produced wood shafts just rolled onto the tester and the grain was in no particular location.

|

|

| From: Dale in Pa.

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Mohican, When you rotate shafts 90*, make sure you zero your spine tester again. That will change the spine unless your shaft is perfectly straight.

|

|

| From: JusPassin

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Good point Dale.

|

|

| From: RymanCat

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

I found not all wood arrows shoot well when you make them up so what I do is I pick it out of bunch and set it aside to arrow a varmint. I found its good enough for that usually.

I have 2 Adams and there are variances between machines. I was going to try to get a digital but they are a lot of money and is it really going to matter that much. No with wood I don't think it will.

I look for the MT peeks to line up with grain.

|

|

| From: dean

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Rogue River, now Wapiti, and Surewood have made shooting wood arrows much more practical for me. The last time I bought cheap parallel cedars off of eBay what came in the mail was a real party. It said 50 shafts, there were 54, those ended up being the most expensive 6 wood arrows that I ever had. Most were not even worth the feathers for shoot away junk arrows.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Here we go again. LOL.

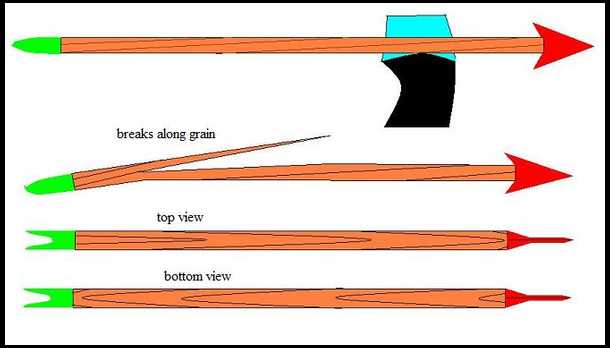

The reason why the groove is aligned perpendicular to the grain is for safety. Put these >>>>>> pointing to your hand so the arrow breaks up and away.

It has nothing to do with the times of self nocks.

BTW I've seen a difference of 2 #'s on some shafts. Most of the time no difference on shafts from lumber. Quite a bit of difference on shoot shafts. I check spine, rotate a 1/4 turn and cut the nock straight up to the greater value.

Having said this I believe it also makes sense from a physics standpoint when you consider how the arrow comes out and wiggles side to side albeit imperceptibly if tuning. is on.

Jawge

|

|

| From: TSA

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

i agree with pearl. another thing to consider, is yes- that grain is perpendicular to the riser upon release, but after the nock leaves the string, and the arrow starts to rotate- the paradox action still occours in a side to side motion, as the shaft rotates- the flexing does not follow the rotation of the shaft. there is a bit of erratic movement- but for the most part the shaft maintains its side to side flexion relative to your bows riser, in fact its that rotation that actually helps in stabilising the paradox action as well.

we spine shafts on the edge grain, because that is the industry standard, but i say shoot them where they shoot best!

|

|

| From: RymanCat

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

For this reason is why we used to buy when it was practical 100 lots to sort them out. When you find really good woodies that are flying really well tha't's when we joked ok this arroow gets a broad head.LOL

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Lots of food for thought here.I came away with always locate grain perpendicular to bow with self nocks. It is O.K. to rotate plastic nocks on the odd arrow, to match arrow spine in same direction. If there is a run out It cost nothing to locate it where it will go up and away from hand. I love the days when I learn something.>>>----> Ken

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

I agree with Jawge 1000 percent.

I've seen what can happen when the grain is turned vertical instead of horizontal. It ain't pretty, and that was with top shelf shafts, with zero run out.

Rick

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

I have yet to have a wood arrow break at release. I wouldn't want to even start to venture a guess on how many 10s of thousands of wooden arrows I have flung.

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

[[[ PEARL DRUMS: "I wouldn't want to even start to venture a guess on how many 10s of thousands of wooden arrows I have flung." ]]]

I'm the same way, except I have had them break. One time it sent about 12 inches of the back end of the arrow through my bow arm.

All because I was rotating nocks to match up spine, and got one turned a little to far.

My opinion - you can safely go about 30 degrees from perpendicular to the strike plate. After that you're asking for trouble.

Rick

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Amen. One accident is too many. It cost nothing to be safe. It is also very rare for a metal nock to be dangerous. A lost eye isn't pleasant and tie on nocks work so well.Take care.>>>---> Ken

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Rick: Shafts with zero runout don't just break regardless of the nock orientation. If there severely underspined or cracked from previous use and not checked for damage, then yes they can. If you shoot wood shafts, its necessary to check each arrow after being shot. I do it religiously.

Bob

|

|

| From: Renewed Archer

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

I'm a little confused. Just starting to make arrows and none made yet, but a lot of shafts have been spined. It's been my understanding that you measure the spine with the grain veritcal on the spine tester first, then rotate the shaft a number of times and re-test until you get the highest reading. Then that's the spine of the shaft which "should" be where the grain is vertical but it isn't always exact. But then you're saying you should rotate the grain when putting on the nock, so the axis of the highest spine and grain lines are perpendicular to the bow window when shot?

Or am I missing something?

|

|

| From: Rick Barbee

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

They were brand new POC, and in perfect condition Bob.

I'm just as religious about checking them as anyone. Probably even could be called anal about it. Heck, just last week I probably saved one of my students from a mishap, because I was flex checking his arrows.

The woodie that went through my arm was being flex tested before every shot as were all the others, because I was "suspect" of the process.

Turns out, my suspicions were correct, and I paid the price for it. I've seen many others crack or break due to the process of nock rotation for matching of spine, and that's how I discovered I could rotate only about 30 degrees before needing to stop.

By the way - the lot of shafts of the one that got my arm were 115# static spine, cut to 30" BOP with 145gr points. Shot from an 80# (at my draw) recurve. They weren't even remotely under spine.

Folks can do whatever they want to do, but I'm turning the grain of woodies to 90 degrees (or reasonably close) of the strike plate. 8^)

Rick

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Renewed: Its all about how the shaft bends. in the spine tester the grains is vertical and the shaft bends vertical when the weight is placed on it, on the bow the grain is horizontal because the arrow bends horizontal when shot.

Bob

|

|

| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 18-Nov-17 |

|

Dalei n Pa: "Mohican, When you rotate shafts 90*, make sure you zero your spine tester again. That will change the spine unless your shaft is perfectly straight. "

You are so right Dale, I caught myself forgetting a few times. TLM

Wood shafts are fascinating to me thanks to all for getting the information into this thread. TLM

|

|

| From: Renewed Archer

|

|

|

|

|

|

|

| Date: 19-Nov-17 |

|

aromakr, thanks. That is a clear explanation!

|

|

|

|

| From: picapica

|

|

|

|

|

|

|

| Date: 19-Nov-17 |

|

In any given batch of a 100 matched shafts from a good vendor, how many will you typically reject when you examine them more closely than a vendor can reasonably afford to?

|

|

| From: Will tell

|

|

|

|

|

|

|

| Date: 19-Nov-17 |

|

I get shafts from Rose City and only a couple out of a 100 are not good. I spine check every arrow and the grain and always put the stiffest side next to the bow. I shoot cock feather in, probally doesn't make a difference but seems to work for me. I shoot lightweight bows and really like 5/16 shafts over the 11/32 shafts spined around 45 pounds. Most of the arrows weigh close to 450 gr. complete.

|

|

| From: KStframer

|

|

|

|

|

|

|

| Date: 19-Nov-17 |

|

Anyone ever looked at design values for wood for construction? Take a good hard look at the difference btw compression perpendicular and compression parallel to the grain. Big difference. Grain orientation shouldn't even be an argument. The info is out there and has been for a long time.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 19-Nov-17 |

|

I make my own wood arrows. Most are very good to incredibly good. Those that just don't to shoot well get busted and used for kindling. I don't even begin to mess around trying to get it to shoot well, there's already plenty of work in the arrows.

|

|

| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 19-Nov-17 |

|

KStframer, My apologies, and I hope I get this right. You are saying that compression perpendicular is much stronger? TLM

|

|

| From: KStframer

|

|

|

|

|

|

|

| Date: 19-Nov-17 |

|

Nope. Compression parallel is much stronger. Think about how much weight a 2x4 can hold when it's placed horizontally (i.e. floor joist) vs vertically (i.e. a post).

Same thing within an arrow. We can all agree that force is applied horizontally with finger release, side to side. With the grain parallel to the string (up and down) the load would be 90° to the grain (perpendicular), place the grain 90° to the string, the load would be parallel with the grain.

Another part of the equation is taking into account the horizontal shear which is a whole other can of worms.

All im saying is that construction design values that have been around for quite awhile agree with the overall consensus of where to place the grain in relationship to the string. There's a quantifiable reason wood is stronger when loaded one direction versus another, people figured this out long before the internet or electricity for that matter.

Not trying to ruffle any feathers here, but seems like a nonsensical argument.

|

|

| From: Snag

|

|

|

|

|

|

|

| Date: 20-Nov-17 |

|

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 20-Nov-17 |

|

Thanks. A picture is worth a 1000 words and should clear it up for everyone. Happy Thanksgiving. >>>----> Ken

|

|

| From: The Lost Mohican

|

|

|

|

|

|

|

| Date: 20-Nov-17 |

|

KStframer, Thanks for the explanation. It is appreciated. TLM

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 20-Nov-17 |

|

If you are using shafts with grain lines running top to bottom, like the diagram shows, that's a dangerous situation.

Jawge

|

|

| From: Snag

|

|

|

|

|

|

|

| Date: 21-Nov-17 |

|

If you get your wood shafts from folks like Surewood Shafts you’ll get grain that runs throughout the full length.

|

|

| From: GLF

|

|

|

|

|

|

|

| Date: 21-Nov-17 |

|

Get an old set of bear woodies from the sixts, or any other brand and you'll see nocks were put on however they ended up. There was no rift to align till Japan started buying up the straight grained old growth. If you have no rumouts history proves it doesn't matter which way unless you use self nocks. Shafts with runout weren't sold for arrows. That's why I stopped using poc.

|

|

| From: GLF

|

|

|

|

|

|

|

| Date: 21-Nov-17 |

|

I was going to try wapiti shafts because he used to advertise no grain runout. Evidently he's found a buyer for the straight grained wood because now his websight says at least one grain that runs end to end. that's no better than Rose City. I'll stick with Sitka spruce or some other wood I guess.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 21-Nov-17 |

|

I know, GLF, though I never remember buying any shafts that were milled parallel. Don't know about bought arrows in the 50s-70s. Can't say. Jawge

|

|

| From: Shorthair

|

|

|

|

|

|

|

| Date: 21-Nov-17 |

|

I use the ACE spine tester that is mounted on my wall. I always measure both across grain and with grain. This is to just get a spread of where my spine may be for group of arrows. Yes, I still mount all my string nocks with it perpindicular to grain ...just habit.

I have never found a shaft that was EXACTLY the same from with grain to across grain.

Dont over think this stuff.....if the grain is good, the arrow is straight and it spines where you want according to how it is shot on string....enjoy your bow and shooting.

keep em sharp,

ron herman

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|