| From: Inmyelement

|

|

|

|

|

|

|

| Date: 13-Sep-17 |

|

I have a homemade crester that I have only used for carbon arrows in the past. The shaft on my motor is 6mm and with carbon shafts I can slide the arrow over the motor shaft and everything works great. I'm working on wood arrows right now and have a lot of wobble. I've tried various metal tubing, rubber tubing, rubber inside of metal etc. Going to look into the possibility of a small drill chuck. Any other suggestions? Being this is my first attempt at wood arrows they aren't perfectly straight, which is proving harder than I thought. How much will a little bend in wood arrows effect cresting? TIA

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 13-Sep-17 |

|

I've crested many hundreds of wood arrow. Wood arrows need to be eyeballed and straightened prior to cresting, or you'll get less than stellar results. Any kind of arrow hop at the crest is gonna suck big time. Just tweak em until they don't hop. You'll get it, it just takes practice. Have fun.

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 13-Sep-17 |

|

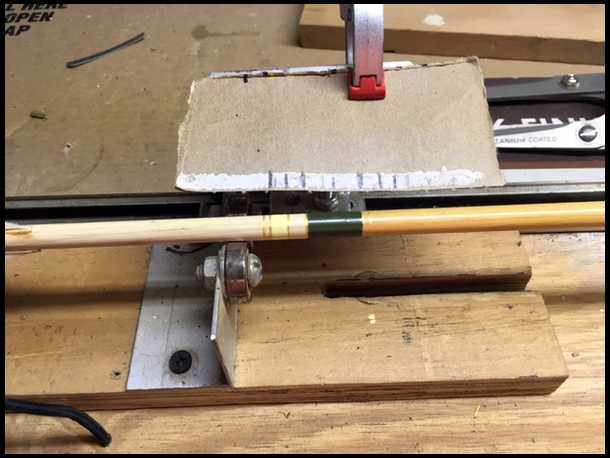

Put the point end in the chuck, or what ever you are using for a chuck and the nock end away. Also make your cradle so it can be moved, even if the arrow is slightly crooked where ever the cradle is, the arrow is spinning straight there. In the picture, the chuck and point are to the right and the nock end to the left. That is a bifold track behind and my cradle slides against that.

|

|

| From: StikBow

|

|

|

|

|

|

|

| Date: 13-Sep-17 |

|

Any ideas for chuck? I used a piece of surgical air tube, but it slips too easily

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 13-Sep-17 |

|

I bought the chuck replacement for the Bohning lil Crestor. But my motor only had a 1/4 shaft. Trouble with a drill chuck is it leaves marks. They are available from woodworker supply houses.

|

|

| From: StikBow

|

|

|

|

|

|

|

| Date: 13-Sep-17 |

|

Thanks. Good advice

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

If you chuck it up on the point end the marks should be gone after tapering.

I've had the same problems and might just get a small chuck and also try the suggestion made by Hal

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

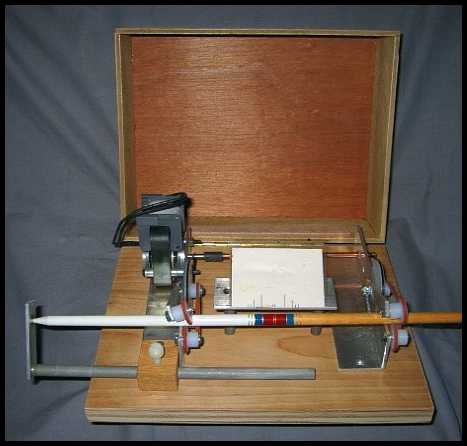

Regardless of what kind of chuck you use, your not going to eliminate the wobble when the shaft is turned by the end. You need a machine like this, that turns the shaft need where the crest is being applied. This is the "Phillips Pro crester"

Bob

|

|

|

|

| From: Inmyelement

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

Thanks for all the advice. I would love one of the manufactured crester, but they all seem to be in that $175 range. I'm didn't pay that much for my Samick Sage.

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

Brent: They are certainly not cheep, however I speak from experience, you will nickel and dime yourself silly trying to make a silk purse out of a sows ear. And they just will not do what you want them to do. A friend of mine and myself developed this crester some 25 years ago and I've found nothing better, and will last for generations. They are an investment that can be handed down to your kids and grandkids. I'm still using the original proto type after 25 years of commercial use. The first 15-20 years it ran 5-6 hours a day 6 day's a week and is still going strong.

Bob

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

That's a fine piece of equipment. If I were a pro there would be something of that type on the bench.

|

|

| From: Inmyelement

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

Can you crest fetched arrows with that machine?

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

I have one of the Pro Crestors as well. Had it for at least 10 years. Only ever had to change the belts. Also have the Spin rite Crestor, an other great product. I really like both and use them interchangeably. I sold my home made one with the store bought chuck. It worked fine for aluminum shafts but I got tired of wavy lines with the woods. No matter how well those shafts spun they always seemed to be wavy in the crestor.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

I'll be danged. I had no idea that crester was designed and made by you Bob. That is a fine piece of work. Very nicely done.

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 14-Sep-17 |

|

Bob.. I didn't nickle and dime myself and the crestor I have $10 in works great. Just have to be smarter than the crestor :)

|

|

| From: trad47

|

|

|

|

|

|

|

| Date: 15-Sep-17 |

|

Beautiful crester! Bob.. where did you find the right Motor and parts to cobble the setup? I have always-wanted To put on few bands of color. Really nice!

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 15-Sep-17 |

|

Guy's I don't build these, they are built by my good friend, Kurt Phillips. He and I designed the machine. Kurt builds the innards I do the box.

Bob

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 15-Sep-17 |

|

Well, you guys built a fine tool for sure.

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 15-Sep-17 |

|

If you want extremely fine and professional work, you NEED a tool like Bob's.

If you just want to decorate them a bit you can do it by rolling the shaft along the edge of a table and hold the brush in your other hand.

Not saying this to bash or denigrate anybody's equipment or workmanship. Just saying that it can be done and the end product will be your own.

|

|

| From: Inmyelement

|

|

|

|

|

|

|

| Date: 15-Sep-17 |

|

For now I just won't crest wood arrows, I can get a pretty good line on carbons. Wish I had that kind of money to spend on decorating arrows but on a single income with 2 5-year olds a crester falls in the wants, not needs, category. I'll keep trying to find a way to make my current set up better.

Where I made the mistake this time was assuming I would be able to crest wood arrows the way I did carbon. Thinking this I did a 2 tone stain on the shafts but didn't care about how clean the transition was because it was going to be covered by cresting. Oops. So to keep plugging along on the arrows I taped off the transition and painted them. I call it minimalist cresting.

|

|

|

|

| From: Sailor

|

|

|

|

|

|

|

| Date: 15-Sep-17 |

|

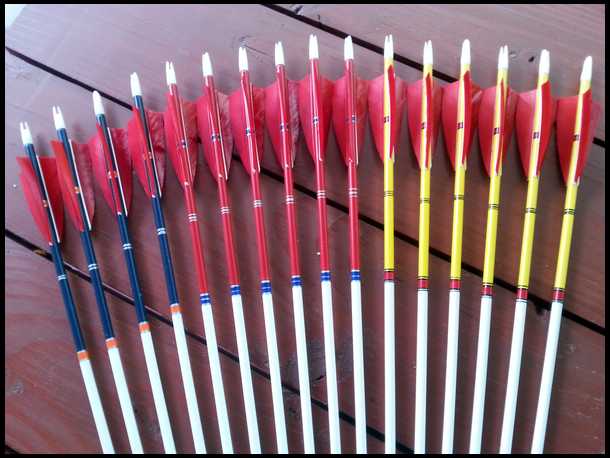

I made a homemade creater from just stuff I had laying around. It is certainly not as nice or easy to use as a professional model but it does a pretty good job. I do chuck the point end and it would work a lot better with a better chuch. Here are some arrows I made for my grandsons.

|

|

| From: Sailor

|

|

|

|

|

|

|

| Date: 15-Sep-17 |

|

Sorry that picture is blurry. Hope this is better.

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 15-Sep-17 |

|

Sailor... thats one of the tricks with a direct drive crestor, put the point end into the chuck, not the nock end.

|

|

| From: Shifty

|

|

|

|

|

|

|

| Date: 18-Sep-17 |

|

I crest before i install the nocks and like Hal9OOO my cradle is movable too.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|