| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

For many years, I have made arrows from board stock by hand planing.

The process is satisfying and relaxing...kind of my time to slow down.

http://traditionalarchery101.com/shafts.html

I rip the stock into 7/16" x 7/16" x approximately 32" so I can choose the best part.

Measurements vary according to the density in that I take samples.

My arrows are 29" to the back of the point.

Jawge

|

|

|

|

| From: bodymanbowyer

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

And they fly just fine. I have some you made. They're just a little shorter now and still riding the air :-) JF

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

I remember that. You still have those. Wow. Jawge

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

I compress the shafts with a round shafted screwdriver, heat treat and straighten. I usually bend and compress with the screwdriver to straighten them.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Here are the finished arrows.

Batman has been suggesting that I post these. :)

I usually give them 2 or 3 coats of polyacrylic brushed on.

They are self-nocked and wrapped with artificial sinew.

The feathers are also wrapped with same.

The arrows are crested with waterproof paints.

More on my site.

http://traditionalarchery101.com

Jawge

Jawge

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

I did not mean for those to be so large. Sorry.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Nice. I particularly like tht the crests and bands are not all exactly the same size. Over the last few years I have started doing the same.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Thanks. Yes, nothing fancy. Crests are done by hand as are the arrows. Jawge

|

|

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Some years back I considered doing this, making shafts. I was looking to use Doug Fir. The Doug Fir I looked at was for window frames and such. It ran about $7 a board ft. My concern was how many shafts would I get in the spine I use from a board? I needed at least 65# spine. So my question would be out of say a 8ft. board how many shafts do you get you can use?

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Good doug fir is very straight grained. I have made maybe twelve dozen arrows from DF and in my opinion it is the best arrow wood. I dowel mine with Veritas tool, but considering if you have really superb grain you can hand plane an arrow from a 1/2 by 1/2 rip. I find it a WHOLE lot easier tor squares, then kick tablesaw to 45. degrees and make octagons, and plane from there using Georges technigue, In fact George got me started making arrows using that simple technique. Thanks again George.

|

|

| From: BowAholic

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

very cool and definitely on my bucket list. thanks for sharing. Bob

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

bodyman, I am glad you still have them.

M60, you can start with 3/8" and add for the thickness of the saw blade and get an idea.

If you are going to hand plane, I never had much luck with fir. The blade dug in. It is probably me though.

Thanks, riverwolf and bowacholic.

Jawge

|

|

| From: bradsmith2010santafe

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

those are fantastic, great job... I hope to try that in the near future,, do you think red oak would work, I have a really straing grain board I was gonna use for a bow, but would like to make some heavy arrows,,???

|

|

| From: feathercast

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Very nice! I've made several dozen from ash I get from a local sawmill. Buy it by the dump truck load. I use the Varitas dowel jig as well. Let me ask, how & why do you heat treat them?

|

|

| From: BATMAN

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Hi JAWGE, See what all kinds of COMPLIMENTS YOU GET after I whine and plead and beg for You to show off the PURTY ARROWS? Do wish that those first photos of the pare shafts had come out a little better. OH WELL! The finished PRODUCT LOOKS GREAT! Go do some more! Love to see build-a-longs on bows, arrows and such. I am a total klutz with my hands so I stand in AWE of people who can do things like that.

|

|

| From: tracy warren

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Thems good looking arrows George.

|

|

| From: Gifford

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

No doubt about it, Jawge builds a good arrow. He gave a demonstration at MoJAM 2003.

I still have 3 of the 4 I got from him. One sadly is somewhere on course two.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

brad, red oak works fine. Just take awhile with hand planing.

feather cast, I think it makes the arrows tougher. I just rune them over a plumber's torch for 5-10 minutes.

Batman, LOL, I am slow.

thanks, try.

Gifford, you still have those. That was a nice trip. Got to meet some nice folks. That's something I remember.

Jawge

|

|

| From: Buzz

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Very nice.

|

|

| From: Frisky

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Those are great! They look really strong too.

Joe

|

|

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Really nice arrows George.

Brad, I buy straight grained 3/8" wooden dowels and run them through a doweling set up I bulit and turn them down to the diameter I need to match spine. The shafts get super hot going through the cutter and I'm convinced it helps them stay straight, and it also burnishes the shaft very hard.

Then, I taper the nock and point end to match weight. They are tough and shoot very well.

I use the same set up to run square stock through to make shafts as well.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

Thanks, fdp. I burnish them, too, after heat treating. Jawge

|

|

| From: WV Mountaineer

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

How do they do George? I always wondered why we don't see them for a option in wood shafts. God Bless men

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

WV, they shoot just like any other arrows out of my self bows. Well, they take some time to make. Jawge

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

Nice Jawge. Your talent and commitment to the primitive end of archery is impressive. Hope you and Joni are doing well.

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

George thanks for a excellent thread ....

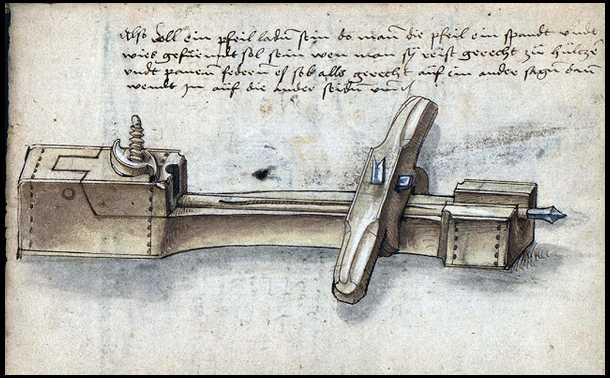

... about 10 years ago I was fortunate to be offered a private rummage through the vaults of the Mary Rose artifacts. Within the tools was a small wooden plane. Some of the blade remained intact and it was clear that the blade had been ground into a concave shape in order to plane round dowels. Because of the size of the plane and the curve of the blade it was thought to be an arrow makers plane ..... just wondering if anyone's come across a modern day equivalent.

|

|

| From: WV Mountaineer

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

Ok. Do they stay straight? Also, how do they rank in weight versus DF or Spruce? God Bless men

|

|

| From: M60gunner

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

Phil, I have done some research on hand planes past and present. You ask a great question and to answer you I have not seen any with a blade or name you mentioned. This also raises the question of what kind of tool was used for doweling even after archery fell out of favor as a weapon of war or providing food.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

Thanks, George. We re doing ok.

I need to mention that is NOT my method. It has been around for centuries.

Phil, you are welcome; yes such planes are in a woodworker's tool box. I have one but don't use it. I prefer the straight blades. I use a 1 inch bladed plane...thumb plane... which I inherited from Dad.

3 Rivers sells an arrow shaft plane.

WV, these arrows are 490 grains...actually all 6 are. LOL. Yes they straight. I've found that white pine is a quick planting of 20 minutes while harder woods need double that time. I like the white pine because it is a good trade off and is readily available.

|

|

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

I doweled my last set out of white pine and the results were excellent. They came in with weight similar to George's.

The board was flat and straight. The blanks and shafts all had a considerable curve to them. I was happy to discover that they straightened easily with heat and bending by hand.

All in all, a good Arrow wood.

BTW, I don't have a spine tester and don't spine my hand made shafts. There were seven arrows in the batch and I just tuned the arrows and a bow together and was all set.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

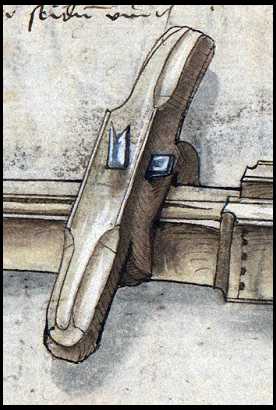

The plane I use. Nothing fancy. It's a thumb plane with a 1 inch straight blade. I'm just a simple man who loves hand tools.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

That plane was Dad's as was this one.

Dad gave me my love for working wood. I learned a lot from him and wish I could have learned more. May your memory be eternal.

For those of you interested in trying this age-old method of making shafts, I wrote it up on my web site years age.

http://traditionalarchery101.com/shafts.html

As always, questions welcomed.

Jawge

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

James Duff has a whole chapter on shaft making in "Bows and Arrows." The book was first printed in 1929 and is still in print.He goes into historical practice and the methods of his own time.

Duff speaks of all the aspects mentioned above and says that white pine from the outer parts of the butt log was not to be sneezed at.

He does find white spruce to be better.

I find red and black spruce to be as good as arrow wood gets, but I just pick out a good clear board of any spruce when I buy arrow wood. (I usually salvage my arrow wood for free. I even used the sound board of a piano once--not so very good.)

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

Thanks, Longcruise.

You jogged my memory.

I like to choose straight grained stock. I also like tightly grained stock. I feel that gives me the > spine. Jawge

|

|

| From: Phil

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

I love threads like this .... thanks George

|

|

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 08-Jul-17 |

|

James duffs book is one of the best accounts of how traditional Victorian fletchers made arrows even though it was written in the 20 th century.I myself can tell you that it's very true in just about every aspect as I inadvertently discovered that the things he mentions in regards to arrow making to be true.I hand make my arrows and hand foot them too.My only machining is initial sawing of the blanks and a light spin sand to accurately size my shafts.My weapon of choice is an English record adjustable throat low angle block plane.I routinely make a couple of hundred shafts per year so I do know quite a in that area.I just moved house and discovered I actually have thousands of blank arrow shafts and pre sawn footings.It took me many years to teach myself all the finer points of arrow shaft making and I actually do 90% of what James duff does.My big dissapointment was not having access to James duffs book earlier.I started making footed arrows at 10 years of age and am now 57.George knows the feeling of crafting shafts and is very kind in showing how to do it on his web site.Not only arrows but self bows too.Yeah George awesome arrows and I hope to make a set of your style trade points soon as well.Not many of us do it by hand these days.Oh Phil you may have seen this but this is really old school.

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 08-Jul-17 |

|

Another pic

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 08-Jul-17 |

|

This time?

|

|

| From: Osr144

|

|

|

|

|

|

|

| Date: 08-Jul-17 |

|

This is just a fraction of what I have .I figured maybe 1000 but after moving maybe 3000.They are still in storage but it amazed me what one can accumulate 23 years in the same house.I found lots of other Archery gear too.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 08-Jul-17 |

|

Thanks, OSR. Like you I've los track of then. of arrows I've made. Jawge

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|