| From: Tracker0721!

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

Apparently arrow shafts have a wider range of diameter than taper tools and that's caused 1 broken taper tool and a stalled project on a dozen shafts. 3rivers little blue taper tool was a tighter fit than bearpaws but even bear paw keeps at just about the same tolerance. Does anyone do any better? Or maybe tru-center? No grinder, travel a bunch living the nomad life in a camper.

|

|

| From: meatCKR

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

Always have good results with the tru- taper.

|

|

| From: meatCKR

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

Oops - meant the tru-center tool from 3rivers.

|

|

| From: RymanCat

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

bear paw machined hands down. you can get an adapter and use drill too.

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

tracker the three rivers tool is ok but they have the bushing sizes to close for most shaft sizes meaning the 11/32 shafts work best with the 23/64 bushing my suggestion is take the 5/16 bushing simply drill it out to 23/64 then ream it to 3/8 and you will be fine you will most likely never use the 5/16 bushing .so the 23/64 shafts will now become 3/8 dia bushing and use the 11/32 shafts in the 23/64 bushing .

|

|

| From: Orion

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

Can't do too much if the shaft is too big for the tool, but if it's too small, just wrap some masking tape around the shaft until it fits snugly. Should be possible to get a decent taper with just about any of the tools.

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

when i built my taper blocks those are the exact dimensions i used they work fine to this day basically you are 1/64 over size

|

|

| From: Scooby-doo

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

BEST makes the the Best. I believe out of Italy. I have had one for 20 plus years and it does all sizes of wood shafts. Shawn

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 13-Jun-17 |

|

Absolutely nothing works anywhere near as well as a sanding disk and V-block set at the correct angle. Done in seconds with no sore fingers and no splintering, even when tapering hardwood.

|

|

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

Tru taper V2 has never let me down. I use it on parallel shafting, cane, boo, shoots and hard woods. Your budget plays a big role. You can spend, $5, $35, $85 or $180 to accomplish the same end results. How many arrows to you make? Another important factor.

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

I would be willing to bet that those of you that are satisfied with a tapering tool who's guide is a hole, have never really taken a close look at your tapers. For a taper tool of that type to work properly, the shaft fit to the hole must be very snug so there is no tipping of the shaft in the guide, otherwise you will get a crooked taper. Take a close look at your taper. If the line where the taper meets the body of the shaft is not 90 degrees to the axis of the shaft, its telling you the taper is CROOKED! Its that simple.

Why is this important? The nock end of the arrow is what starts the arrows flight. If the nocks are crooked they will start the arrow off at an angle. Now since there are 360 degrees around the shaft, there are 360 different positions that nock can be in, where as there is only one position a straight nock can be in. Listen to what Jim Davis said he is absolutely correct.

Bob

|

|

| From: Nemah

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

My Woodchuck always had too much play in the shaft which allowed the disc to move in and out while sanding. Not good. I agree with Jim Davis... The best taper tool is a disc sander. I have 3....an 8" sander for tapering arrows, a 12" sander for tapering laminations when making bows, and a 3rd for general sanding and shaping. A MUST have in any shop. Richard

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

Well all things considered most WOOD shafts are not perfectly round so you cannot make you tooling that close of tolerance it simply will not work that way a V block works good but it's not perfect either .

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

I'd be interested in hearing more about Shawn's "Best" tool, because I don't think I've ever heard of that one before...

But I have seen Nemah's work, and that man clearly knows his way around a woodshop!

|

|

| From: strshotx

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

For me it's hard to beat a Woodchuck,quick and easy and you can make small adjustments on the taper for the best fit.Bought my Woodchuck over 20+ years ago and still works great!

|

|

| From: mgerard

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

I don't need Olympic precision on my wood arrows. The aluminum deluxe Bear Paw taper tool works fine for my needs and paltry shooting abilities. And it is easily portable for a nomad:>)

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

I'm going to agree with Mike Gerard. I have one of the Bearpaw cheap models with replaceable blades. Dang thing cuts great tapers that spin just fine. Extra blades are less than $5.00 plus shipping. If I was doing dozens of arrows a week, I would get something more elaborate. Well, actually, I would just take them over to hvac tech, he made one many years ago that cuts as perfect a taper as you can get...nock, point....and even for making tapered shafts.

|

|

| From: Seahorse

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

I gave up trying to find a taper tool that works worth a hoot a long time ago. I made a jig for my disc sander. Works perfectly every time.

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

hvac tech : "Well all things considered most WOOD shafts are not perfectly round so you cannot make you tooling that close of tolerance..."

I make my shafts and they are round within .0005" out of my router setup. The intersection of the taper and the surface of my shafts is an even line around the shaft.

(I can still miss with the worst of them. :)

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

Its true the commercial wood shafts are not perfectly round, however the "V" block will make the tapers that are 90 degrees to the axis of the shaft.

Bob

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

Well i have checked my tapers on a sine bar they are within 10 min that is the nock and point tapers which is well within range i ground a 11/32 drill blank to perfect 11 degrees and one to 5 degrees and the glue on broadheads are not that close . i have the blanks to prove the are 5 and 11 it is important that the taper is square to the shaft if the shaft is not perfectly round that will still affect the taper angle slightly V block or not

|

|

| From: Scooby-doo

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

The problem with a lot of the posts on this subject are the OP was not talking about a 100 or 200 dollar set-up. He was talking about going from a pencil sharpener plastic 8 dollar taper tool to something similar that does a better job and does not cost a bunch!! Again the "BEST" taper tool out of Italy does an excellent job for under 40 bucks I believe. Shawn

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

Trying to do point and nock tapers on a wood shaft with a twirlydoodle would be a big pita for me. I hate using tools that aren't worth a crap in their basic design. I ALWAYS spend some money and get a tool that is a pleasure to use. If there's no room for a Woodchuck, just put a ceramic blade in your angle grinder and cut a slot for the trade point you just made out of discarded skilsaw blade, using a metal cut off wheel in the grinder. Works absolutely perfect. LOL

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

scooby doo i clearly told the guy how to fix the problem for cheap simply take the 5/16 bushing and make it bigger i explained the exact sizes above cost is nothing and it will fix the problem .or buy one like you have .what is the name of you tool ?

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

scooby doo i clearly told the guy how to fix the problem for cheap simply take the 5/16 bushing and make it bigger i explained the exact sizes above cost is nothing and it will fix the problem .or buy one like you have .what is the name of you tool ?

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

sorry double post

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

You can freehand the cut with the grinder if you're good...like I am...or clamp the grinder in your bench vise and feed the arrow into the blade. Either way,,,,perfectly sized slots for Skilsaw trade points glued in with hot melt or epoxy. Screw that pine pitch and ground up charcoal stuff..... lol imma hijack this airplane.

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

I agree these are wood arrows they are never perfectly straight never perfectly round etc so i cut the best taper i can and it is ok but those bearpaw tools are ok they cut a very accurate taper i measured them .

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 14-Jun-17 |

|

Been using my own power taper tools since the middle 80's, like Bob said, nothing gets the tapers as straight every time. I have a sliding stop to adjust for the depth of the tapers and my rail is about 12" long so you are using a lot of the arrow to make sure its straight. I have used it to taper the ends of the goal posts on string jigs and the angle iron bolted to it is used to taper the ends of bow laminations to glue together at the center.

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

Actally, "using a lot of the arrow" increases the chance of a kink in the arrow affecting the taper. I use a about the last 6 inches in a V-block. If there is a kink farther up the shaft, straightening it will not misalign the point.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

Off op topic but related.

When making tapers on my Woodchuck, I spin the straightened shaft in a hs 2500 rpm drill, and push the shaft down into the vee groove with the palm of a gloved hand. This beats rolling them by hand by a mile.

I do the point taper first with the untapered nock end chucked in the drill. Glue on a blunt, and then taper the nock end. F-a-s-t and precise. No tedious farting around like watching four chiefs on a city crew watch the two guys in action lol. I use tools everyday since 1973 and if there is one thing I don't like, it is working slow and inefficiently. I shoot blunts all the time btw. Just tapered twenty three hickories the other night.

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

So, Bob....

Any reason that you couldn't glue on a FP, rather than a blunt?

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

I disagree, if there is a kink (which my arrows don't have) the nock will be aligned with the angle of the kink, not the center axis of the shaft.

I have taken those kids fiberglass arrows (spine out at about #50 and are bomb proof) and purposely put the broadhead on crooked to the arrow at that point...why? I taper the end of the shaft a little (in my power taper tool), epoxy on a broadhead and then put it in the spin check to check it. I tweak that broadhead so it spins dead center perfect to the center axis of the shaft, not to the last 4 to 6" because many times they are not straight. The arrow flight proves it is right.

I use the compression method to straighten arrows, but only on the ends, the outer third maybe. I rarely if ever touch the middle of the arrow. All I am really concerned with is that both ends are spinning true to the center axis of the shaft.

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

The best way to get perfectly tapered shafts on both end is simply use aluminum and be done with it NO wood shaft will stay perfect . i was in baltimore a few weeks back and i looked at some rose city made bear brand wood arrows that were every pricey . i picked one out of the box and give it a spin they had field points on them that thing had a bow in it like you would not believe .

|

|

| From: Scooby-doo

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

The name of the tool is "Best Taper tool" do a google search. Hard to find here in the states, Abbey archery, Alt archery services and several other out of country places have them. Shawn

|

|

| From: flyguysc

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

Best solution to tapering nock & points that I have used and pretty inexpensive to boot.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

Yup you can spin taper and sand with a target point in the drill chuck. I just don't shoot targets near as much. Blunts for me around here.

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

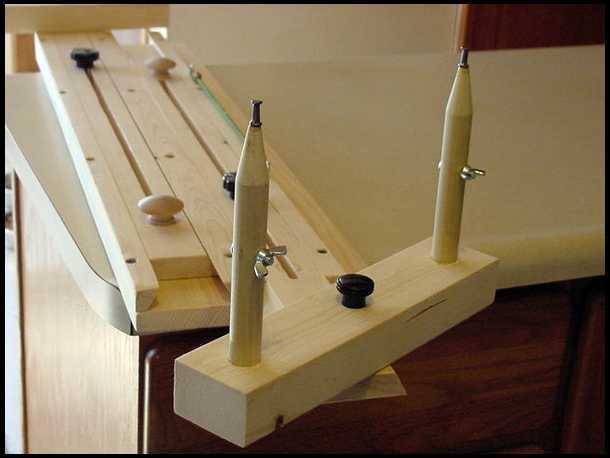

here is my set up . i can run 100 shafts in say half hour the blocks have a built in stop i can do 11/32 23/64

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 15-Jun-17 |

|

i can taper shafts on my belt sander with a set up i have for it .

|

|

| From: Red Beastmaster

|

|

|

|

|

|

|

| Date: 16-Jun-17 |

|

The guy lives in a camper. No room for elaborate systems. Hand held only.

Typical Leatherwall responses.

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 16-Jun-17 |

|

hvac tech... I have cedars that are 2 to 3 decades old (finished) that are still straight today. Got shafts from Joe Howland from the 60's, didn't even have to straighten them.

|

|

| From: Hal9000

|

|

|

|

|

|

|

| Date: 16-Jun-17 |

|

Tapered the ends of these goal posts on my taper tool

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 16-Jun-17 |

|

Red...the discussion expanded quite a bit since the O.P.'s simple question, but that's how it works here. Besides, he could stop by Joe's place in his camper and get is tapering done there. )

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 16-Jun-17 |

|

Yes that would work.

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 16-Jun-17 |

|

alot of of things on here get away from the original post . like i said for the third time for those not listening simply modify the 5/16 bushing .

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 16-Jun-17 |

|

I roll WAY off topic about every other post. lol

|

|

| From: Crossed Arrows

|

|

|

|

|

|

|

| Date: 16-Jun-17 |

|

Some of us are old enough to remember the hand cranked pencil sharpener on the schoolhouse wall. I think they were made by a company called Boston. They did a good job and lasted a long time. I've often thought that the same design for arrow sharpeners would work well. Maybe not as well as some mentioned above, but pretty good.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

10-4 on that CA. Those old school sharpeners worked GREAT on pencil wood. Now there is a tool that is portable and a superb design. Those school room sharpeners have spiral cutters in them. They GROUND the point. With use you could develop a feel for how much pressure and speed it took to get that perfect point.

There is no goofy little kiddie style single blade cutter that approaches those pencil sharpeners in basic design. A Veritas doweler has two planar blades, set in tandem. You adjust the first blade to hog off the material to just slightly large in diameter and the second blade refines the rough cut to the actual diameter desired. This is accomplished with a high speed drill, not spinning by hand. IMO hand cranking a shaft a blank into a single cutter is an exercise in frustration, in comparison.

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

yes it was boston i have one here at the shop . but i have pencils sharpened many with a pocket knife .

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

yes it was boston i have one here at the shop . but i have pencils sharpened many with a pocket knife .

|

|

| From: Crossed Arrows

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

I bet there are young guys here who have never even used a pencil, so this might be another Rip Van Winkle moment.

|

|

| From: Jim Davis

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Boston sharpeners are now made by Exacto.

|

|

| From: Cameron Root

|

|

|

|

|

|

|

| Date: 17-Jun-17 |

|

Without reading all the posts above. I have the perfect tapering tool. Way way way better than the bearpaw. As I understand the sanding disc style is the best one depending on the jig you make for it. Not the wood chuck . Bigger set up. Bear paw makes decent equipment. But it's probably a copy of someone else. I am now bearpaw free and I am going to stay that way. Rooty

|

|

| From: hvac tech

|

|

|

|

|

|

|

| Date: 18-Jun-17 |

|

Rooty that sounds like you were addicted to bear paw .

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|