| From: Bobby B

|

|

|

|

|

|

|

| Date: 28-May-17 |

|

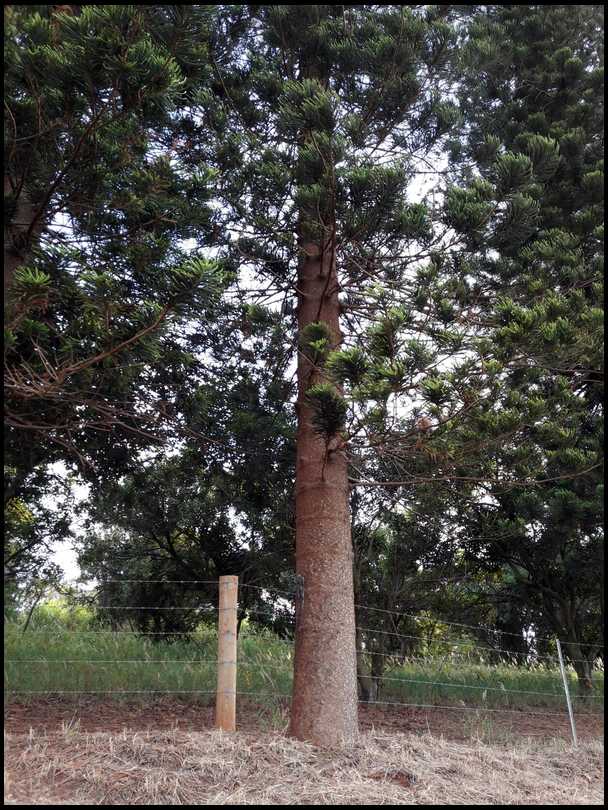

I drive past a stand of Cook Island pines almost daily and an urge to make arrows out of some hits me all the time.

I know that these things have about the straightest grain you'll ever find in a tree. Visually it's pretty remarkable actually. I think all Araucaria have super straight grain. The things grow so straight they look like 150 ft tall bottle brushes.

Has anyone here tried this as arrow stock? Does ridiculously straight grain have any benefits or does it really matter?

We also have lots of species of Ironwood (common grain growth, but it got its common name for good reason.) Thought that could be a good choice.

Just curious to hear what any of y'all think before I go buy a dowel maker and start shaving- ha.

|

|

| From: Bobby B

|

|

|

|

|

|

|

| Date: 28-May-17 |

|

I drive past a stand of Cook Island pines almost daily and an urge to make arrows out of some hits me all the time.

I know that these things have about the straightest grain you'll ever find in a tree. Visually it's pretty remarkable actually. I think all Araucaria have super straight grain. The things grow so straight they look like 150 ft tall bottle brushes.

Has anyone here tried this as arrow stock? Does ridiculously straight grain have any benefits or does it really matter?

We also have lots of species of Ironwood (common grain growth, but it got its common name for good reason.) Thought that could be a good choice.

Just curious to hear what any of y'all think before I go buy a dowel maker and start shaving- ha.

|

|

| From: Bowlim

|

|

|

|

|

|

|

| Date: 28-May-17 |

|

It isn't rocket science, if the grain is good, low run out, high ring count ideally. If when dried you can get spine in decent diameters, which indicates good stiffness to weight. Should be fine.

I didn't find numbers for it, but very generally woods tend to follow density pretty closely, so long as other factors like grain quality and type are similar. Testing for breaking strength is pretty easy. You want reasonable hardness.

Straight grain is the single most important qualifier for arrow stock. Arrows are the most highly regulated wood product in the world, moreso than aircraft wood. Nobody tests every piece of aircraft wood, and then specifies it's use. But straight trees do not mean strain grain. Tight grain, with zero run-out can't be over stressed. However, some woods have lower splitting potential than others, like Sitka. In that case, low runout is less critical, but would always be good.

|

|

| From: Bowlim

|

|

|

|

|

|

|

| Date: 28-May-17 |

|

Good runout is a line that stays within the arrow end to end, so roughly 3/8 over 24. Completely straight was common in POC. Runs out in half an arrow length is not terribly impressive, unless hardwood, or sitka. If the grain wobbles along the way, then an end to end test is lees meaningful.

|

|

| From: Bowlim

|

|

|

|

|

|

|

| Date: 28-May-17 |

|

Does it really mater if grain is completely staight? I have shot many arrows that didn't have great grain, but what you loose out on is confidence. They may be fine. If you have bad grain behind the head, the arrow might break in a stump, but probably not in the bow. One is guessing.

Glass/carbon baking on a bow is completely straight, or in an arrow. That is the gold standard. Anything less is not as good.

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 28-May-17 |

|

I make them out of pine in board stock. More on my site. Jawge

http://traditionalarchery101.com/shafts.html

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 28-May-17 |

|

Pine makes a good Arrow. No need to invest in a doweler right off, check out George's site. Pretty sure he has information on hand planing square blanks.

The cook island pines are intriguing. Are you able to harvest them or purchase boards locally? Naturally dried wood has more "life" in it and probably easier to straighten and keep straight. Kiln drying is too fast and drys and shrinks the outer wood which in turn crushes the inner wood cells.

|

|

| From: Bobby B

|

|

|

|

|

|

|

| Date: 28-May-17 |

|

Thank you all gentlemen.

Not sure anyone here is harvesting Cook Pine to use for anything so I will probably be doing it all myself. I'll need to learn a bit about cutting and curing wood first here it appears.

There are so many other woods that people want for interesting grain and color (koa, mango, monkeypod, sandalwood to name a few) that something as boring as a pine doesn't even register with people! haha

Never would have thought of a method as simple as what you outline George. Very cool - and better yet frugal!

|

|

| From: Eric Krewson

|

|

|

|

|

|

|

| Date: 29-May-17 |

|

The tree in the picture looks like it will have a lot of knots to contend with.

|

|

| From: Bobby B

|

|

|

|

|

|

|

| Date: 29-May-17 |

|

Not sure how knotty it looks. I know that branches seat pretty shallow in the bole but I'm so new that I wasn't sure if you use sapwood or heartwood for shafts.

I'll have to get at it and see what I find.

|

|

| From: Matt Ewing

|

|

|

|

|

|

|

| Date: 29-May-17 |

|

I say go for it and do a build along. Sounds like a lot of work but it would be neat to follow you as you go.

|

|

| From: AK Pathfinder

|

|

|

|

|

|

|

| Date: 29-May-17 |

|

I took one of them down for my father one year and the problem I saw with it was they have very concentric limbs that grow evenly around the trunk and are spaced about a foot and a half all the way up the tree. I suspect finding enough knot free wood will be the biggest challenge. I'd much rather have a bit of grain runoff than curved grain around a knot.

|

|

| From: Bobby B

|

|

|

|

|

|

|

| Date: 31-May-17 |

|

Appreciate the posts everyone.

When I can get the time and gumption to get at this project I'll have to post what kind of mess I make of it.

8^D

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|