| From: RonG

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Folks, does anyone you know of make arrow nocks with a straight slot for the string. I am looking for glue on nocks for my wood arrows that do not snap on to the string.

Thank you for all replies.

|

|

|

|

| From: JFH

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

the old mercury nocks had little to no pinch. check ebay

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

The old index nocks are not snap nocks either. I like the Mercury for wood arrows. For my aluminum I like the snap-on nocks...you can adjust them so the don't hold so tight.

|

|

| From: Nemophilist

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

The Footed Shaft sells mercury nocks. They have a straight slot, they do not snap on.

|

|

| From: Nemophilist

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

The Footed Shaft also sells Micro Nocks which have a straight slot.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Thank you everyone, sounds like the Mercury nocks get my order. I have some, but don't know where I got them from, need more.

Thanks again for the quick response,

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Thanks fellas I ordered 200 from e-bay the fella selling them is not far from me here in Florida.

I get tired of messing with these snap on's. I have been using a piece of piano wire the correct size and heating it and carefully pushing it down in the snap on's and basically making Mercury nocks, but there isn't much left after that....Ha!Ha!

Thanks Frank I will check them out also, the company who made Mercury nocks is out of business, I wonder who is making them.

|

|

| From: stickhunter

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Dang Ron, I just pitched a bunch of those mercury nocks...that’s the way it always goes.

|

|

| From: Jim

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

I sure am surprised that someone hasn’t started manufacturing them again.

|

|

| From: Nocklow

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Hi all,

Anyone ever dealt with this company. There web site says they make a mercury nock. I haven't been able to get in touch with them.

|

|

| From: Nocklow

|

|

|

|

|

|

|

| Date: 13-Dec-18 |

|

Sorry the link didn't post.

http://www.badistributors.com

|

|

| From: Bender

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

OK I know that we're is not supposed to do this, so if you do it, it's on you, but I have figured out a way to handle the "snap" thing.

It does require some effort, ingenuity, and a bit of luck in finding the right tool.

Just a simple flat file, but it needs to be about 1/2" wide and abnormally thin, like about 0.080"-0.090"

Note that most flat file have teeth along the thin edge. You need to grind those off. It's those teeth that screw up a nock and weaken it because they cut into the nock throat and that is what weakens it.

Basically I file off that tiny little tooth that makes the nock a "snap nock."

There is the consistency problem as well. To handle that take one swipe, turn the arrow 180 degrees, take another swipe. Don't just saw back and forth.

Count the strokes. After 2 strokes, once in each orientation, check nock fit. Then do it again. I don't do more than 4. If it takes a lot to get where you want, look into a different nock size, nock make or model, or serving size, or some combination thereof.

This process seems to effectively remove the little tooth. Once you have figured out what gives you what you need Just remember it and you're good for future arrow builds.

No more need to agonize over locating decent hard to find glue on nocks. It opens up your choices to what nocks you can use. And besides it yields a good nock fit, tight enough to keep the arrow from accidentally falling off and risking a dry fire, or missed shot opportunity, but without that irritating "snap" that just eats at your serving.

The downside though is that if I ever lose my nock file I'm screwed.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

I picked up 200 for twenty bucks from the last of the original batch. Thanks guys.

Nocklow a company with the name badistributors can't be good..Ha!Ha!

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

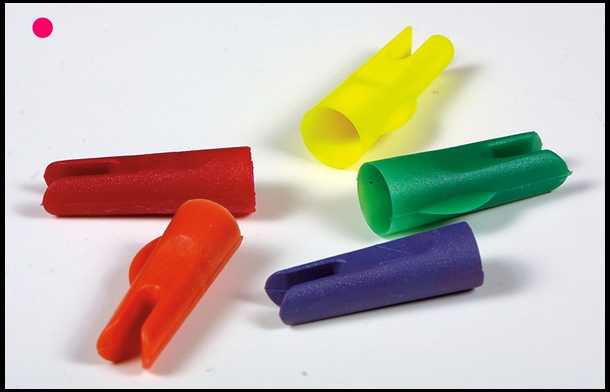

Could be me, but these look a little rough. This is from BA distributors

|

|

| From: Nocklow

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

Ron, they do look to be a harder material then the old stock mercury nocks. I'd like to get some to see how they hold up.

|

|

| From: stickhunter

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

This is where I used to buy them.

|

|

| From: stickhunter

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

Well the link didn’t work. The footed shaft in Minnesota stocks mercury nocks.

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

You know, if you google Mercury Nocks you get hits quickly on the Footed Shaft, FS Discount Archery, and RMS.

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

Looks like Foot Shaft has all colors and 5/16 and 11/32. FS doesn't have them.

|

|

| From: stickhunter

|

|

|

|

|

|

|

| Date: 14-Dec-18 |

|

Yes and the footed shaft is a somewhat small shop, family owned and operated for many years. I’ve been buying from Lamont for 20 years and now I believe it is his son in law that owns the business. Great place to get tapered cedar also.

|

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

Thanks fellas, I just couldn't remember the name of the nocks, I actually had one left, my brain is petrified.

Nocklow, they look a lot more porous than the normal plastic nocks, could be more brittle also, they are cheap enough and worth trying. I think I ordered enough Mercury nocks to last my lifetime.

|

|

| From: Keefers

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

If someone still has the mold it doesn't take long to make 20,000 of them if the mold does a dozen at a time or more.Only thing is once one color is done you clean the barrel and purge it with a cleaner then do next color.Looks like the old material was called "Delrin" and when I molded certain products for Black and Decker that material would burn your eyes and about knock you out if you got a wiff of it. Now the newer ones look as if a glass was used (fiberglass) to help in strengthening it from breaking or cracking. Wished I had a small scissor style or ram molding machine cause I could pump out some nocks and set up molds in about an hour then process it . Just have to make certain material is dry and no moisture etc.There are company's around that do special moldings for things like this so if the mold was found it could be shipped to a plastics molding company and set up. Just needs an operator to keep check of the parts and adjust pressures if something went wrong.Believe it or not if that mold did have say 12/24 nocks made into the mold itself the cycle time could be anywhere from 30 seconds to a minute in curing time and making the next batch.

|

|

| From: Keefers

|

|

|

|

|

|

|

| Date: 16-Dec-18 |

|

Now looking at that green nock a Mold Tech would call that "Flash" and would slightly back off the first stage pressure and see if that took care of it. We also would have an operater use a trimming tool or razor knife to trim that extra material off but pumping out that many small nocks will drive you nuts so a good technician would adjust pressures and cure times etc. I sort of miss my molding days but our company laid everyone off and crossed the border .

|

|

| From: BATMAN

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Hi TEAM, Just for grins and chuckles, I reached out to one of the staff at 3-Rivers. I asked questions about nock life since these things are made of plastic and THAT STUFF will degrade over time. The guy at 3-rivers suggested changing nocks on a yearly basis, whether You are splitting arrows or not. It's a hassle and expense but lots better than "DRY-FIRING" Your bows. These opinions are offered For what's it's worth and Your mileage may vary? BLESSED BE!

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 17-Dec-18 |

|

Thanks Keefers, that is what it looked to me, poor quality control, get it close and punch out a few thousand. The red, orange and blue nock had a lot of flash on them.

Not saying they aren't good, just not the quality of a good molder.

|

|

| From: RymanCat

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Ron I might have some that might work I will have to look when I get home Ron. What size shaft do you have . I will see what colors I have if any. Bare in mind they usually are larger than the snap nocks we see if I have them.

Will pm you. Or send me your e-mail and I can send a picture. What size shafts though.

Cat

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Cat, you are the man, I really appreciate the very generous offer, but I ordered 200 of them through Ricks link and have the footed shaft in mind also. I have one left that I installed on one of my new POC shafts from Wapiti and man does it make a difference. I will never use snap-on's again. It's just the way I shoot that those work for me better than the snap-on's.

Mountain Man offered me some also, but I already ordered from the link.

They will be here by the 21st, thanks again Cat.

|

|

| From: Tim Finley

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

Mercury nocks break in cold weather I don't trust them.

|

|

|

|

| From: Scoop

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

I wonder if cold weather breakage was a batch problem rather than the temperature. I bought a hundred of a red color in the Mercuries and did up a dozen arrows of a heavier weight to tune in an Aspen longbow 25 years ago and broke several nocks right off the bat. The remaining nocks in that batch got tossed and and I used some from another supplier with zero problems after cutting off the bad ones and regluing them and didn't have any more problems.

I do a lot of rabbit hunting and shooting on calm winter days in below zero weather and have not had nock issues and use Mercury nocks exclusively and have done so for many years and from numerous suppliers. All have been with great success, except for that one batch. I'm thinking the mixture or quality control got missed. I'm going to cry out loud the day I can't find any more Mercuries.

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 18-Dec-18 |

|

I had issues with Mercury nocks getting brittle and breaking in less than a season of use. I had used them for decades previously....something changed. I switched to Bohning Classics.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Tim, I live in FLORIDA!!!!!!!!!!!!!!!!

Scoop, That is why I bought 200 mercury nocks.

I have been using Bohning Classics for 5 years and I only had three break, but the Mercury's work a lot better for me anyway.

|

|

| From: Keefers

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

The reason they may have broke could very well be the material they used and the time it sat in the molding process. Something we learned when I installed and molded plastics was that Material had to be dry and once the virgin material hit the atmosphere it was considered contaminated and moisture would set in and needed to dry for several hours with a special dryer just for plastic pellets. Fiberglass used in plastics ad strength and I never understood why company's making nocks don't use it cause it can benefit in several ways especially cold temperatures. We used to do drop tests to see if our tools would break or shatter . I'm sure company's have figured out curing times and plastics by now so older nocks may be questionable. Then again recently Gold tip had an issue with theirs but I believe it's been addressed and problem fixed. There was a clear material I believe called Lexel we used to use where I worked and would crack very easy or shatter and wonder if it was ever used in some nocks. The ends where the throat slides over string has got to have a little flex or can break there or cause a Fischer or crack. Anyway I never understood why and I may be the first to say this and should patent the idea But what about a rubber nock? Any takers on that idea? Remember I said it first lol so I want dibbs on it lol..

|

|

| From: Altek

|

|

|

|

|

|

|

| Date: 19-Dec-18 |

|

Interesting info.

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

Batman, anyone who sells nocks will advise you to buy new ones every year. I have index nocks from the 60's that are still pliable and quite functional. What degrades plastic is ultra violet rays from direct sun....storing in a window that gets sun, etc.

As for doctoring nocks with a file to fit, I do not recommend that at all...weakening the ears of the nock is likely more problematic than a nock that fits tight on the serving. You can adjust the serving if need be or go to a bigger nock...hardly a financial setback to do that. I just put some dental floss in the nock set area of my old semi-recurve so the Mercury nocks will 'snug' on to it.

If I'm using alloy or synthetic arrows I use snap-on and they usually fit very nicely with just the serving. Before I would file a tight fitting nock, I would rather just heat the ears in hot water to accommodate a bigger serving.

|

|

| From: Bodark

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

STOTLER BOW COMPANY MADE NOCKS THAT WERE NOT SNAP ON IF YOU CAN FINED THEM I bought some on this site last year. The leatherwaller I got them from still had black 11/32 ones Gary

|

|

| From: Milo

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

If you don't mind me asking...why don't you like the snap-on nocks? Not a criticism, just a genuine question as I am learning a lot and am quite new to this.

I have several wooden arrows with nocks that do not snap-on, as well as many arrows with self-nocks, and I find them far more difficult to draw with, having to pinch the nock in-between my fingers while I draw back to ensure it does not fall off the string. Am I doing something wrong? Is my serving too thin, and the nocks should be snug even if they do not snap on?

Sorry for hijacking your thread! I am just used to snap-on nocks, so when I started using the non snap-on kind I began to wonder why they even exist haha. I must be doing something wrong here.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-Dec-18 |

|

Thanks Gary,

I agree with you Mr Stout, I don't like weakening anything so it will fit correctly.

Keefers, sorry, I'm too old to start a new business, but if it would work I'm sure someone would have done it by now...LOL!

|

|

| From: Keefers

|

|

|

|

|

|

|

| Date: 21-Dec-18 |

|

Ron I wished I had one of the smaller molding machines and a nock mold just to tinker with possibly a rubber material with a glass or some sort of material to mix in to see how it cured and do some testing on it. Possibly get folks who can bust nocks at 20 yards and try and break or snap them. I wonder if a rubber style nock ever crossed Fred Bear mind since he was such a great inventor? Now when I left the company I worked at that did molding I have a brother that said the company had gotten a 2 part injection mold machine that had a double barrel where once the primary nozzle would inject the main material at around 480 degrees and then the other a rubber material which would use less heat possibly around 360 degrees on top of first material in specific areas. Not sure if the rubber had another material mixed in to make it some what more rigid but just imagine if you will of nocks never shattering if you are shooting target or 3-D coarse's or have arrows just touching the back of another arrow previously shot .I guess what I am trying to explain is if you just mold a plastic nock of a hard plastic then have another injection of a rubber material as an overcoat. If that doesn't work then how about a simpler idea of just adding a little fiberglass into your pellets and give the nocks strength so they won't break so easy or shatter in the extreme cold? That glass is used in many a plastic products now especially battery operated tools cause I used to mold them.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 23-Dec-18 |

|

Keith, I understand what you are saying, I have never had a Mercury nock fail, but a couple Bohnings as they are thinner and more fragile.

Your idea is feasible, but how many would benefit, not to many continuously hit their own nocks.

I think most people hunt and usually only use one arrow so the nocks are safe except in very cold weather, the Mercury nocks are much beefier and hold up well.

I would use an arrow with a self nock sawn or filed in the end of the arrow in cold weather, then you wouldn't have to worry about broken nocks.

I am like you, I would like to experiment with new ideas and see what I could come up with.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|