| From: RonG

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

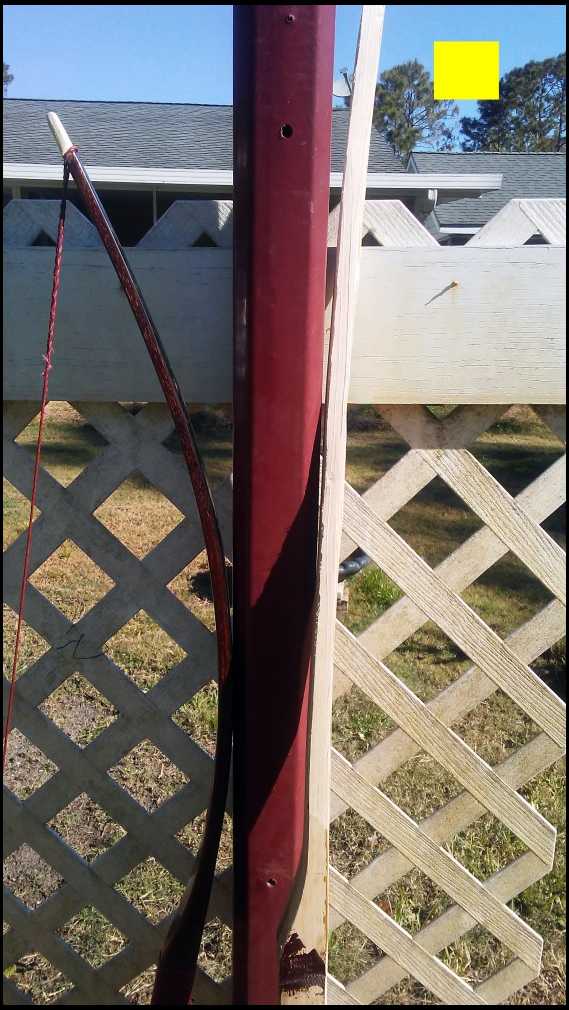

My Hickory was a success, now I'm starting on a Hop Hornbeam self- bow from billets, don't worry this one won't take a year...Ha!Ha!

I probably should have done more before I took photo's. but I'm a little anxious.

Photo is after I cut the N splice in the billets and stuck them together, I got them centered perfect, but a little wavy on my bandsawing. I haven't glued anything yet will probably try to fit the joints better.

My practise piece came out absolutely perfect, Of course.!!!

Now I need to decide to put reflex in when I glue the two halves or glue the billets straight and heat and bend reflex into the limbs, I know that I don't need a lot. the limbs do point forward, i don't know if that is enough.

Thanks for following.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

More photo's

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

|

|

| From: Knifeguy

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Having fun in Florida, love it. Lance

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Ron I would probably be happy with that natural reflex, but you still need to temper it. Great splice work. That is something I never got great at, just good enough.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Do you have to splice two pieces together or can you make it out of one piece if you find a long and straight enough one??

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Sure, you can make a hophornbeam selfbow from full length staves. Sometimes after you cut a 6' log, you might have another short section left that's equally as nice, it's just too short for full length staves. Splicing is easy and strong if done properly. For billets, I try to cut them about 38-40" long.

|

|

| From: throwback

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Ron's at it again. Lol I'll be following along, for sure. I'm planning on cutting some HHB myself this spring, when my health improves enough to get back into the woods. Looking good, Ron.

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Geez Ron!.....can I have your Sopwith ? :)

|

|

| From: Pa Steve

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Definitely addictive. Once you build one sucessful bow it's very hard to stop. Good luck with your new build. I have an osage stave I'm working on right now.

|

|

| From: Draven

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

I really envy you Ron. Weather and time for building the bows you shoot! Good luck with the new baby ... err bow

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

I don't know Chris, your fit on your splice looks a whole lot better than mine. Now to select the proper glue and I will be set I know they are not needed, but has anyone ever drilled and installed dowels where the bow is spliced as extra security, don't mind me it's just my overbuild genes coming into play...Ha!!Ha!

I will have to do like Chris did on his Osage and build up the grip, my hands are kind of on the large size.

Thanks for the comments and help.

|

|

| From: Pappy 1952

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Love HHB, it makes a great bow. Looks like you done well on the splice. Pappy

|

|

| From: Codjigger

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

A fellow by the name of Marc St Louis did an article on making Iron wood bows, that was in Primitive Archer magazine If memory serves.i was saving that magazine in case I got the urge, but now I can't find it anywhere. Sandy

|

|

| From: BowAholic

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Looks like a great start Ron. Marc will likely chime in soon... :)

|

|

| From: Shotkizer

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Looks great. It has got to be a very hard wood. Does hophornbeam work better than hornbeam?

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Shotkizer, Pearl or Jeff will have to answer that one, this is my first HHB.

Thanks Pappy 1952, I have an 18" band saw with a 1" blade which helps a lot.

Thanks PA Steve, Yes it is addictive the more you build the more you want to build, good luck on your Osage, that will be my next after this one.

Throwback, Thanks buddy, hope you get well quickly, I have been doing better since I started getting into this.

Pearl Drums, I got one of those Wagner heat guns just for this. we are going to have barbecued Hop Hornbeam....Just Kidding. Tempered!!!!!

I may add my wife and I have had a cold since Saturday and we thought we were getting better, but things changed, we got a lot worse this evening, we are having an epidemic of the flu this year, I hope we don't have that, I may not post anymore on this until we get better.

Thanks everyone for your replies and support, keep on shooting!!!

|

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 24-Jan-18 |

|

Jawge, It's two billets I put together with an N splice.

Thank you, I have a lot of help if needed, anxious to build this one, Osage will be my next.

|

|

| From: SB

|

|

|

|

|

|

|

| Date: 25-Jan-18 |

|

I went through the self bow thing for a few years. Shot a big doe with my first one. My last one has been roughed out for years now...but really no where to work on bows anymore...Maybe someday it will get finished.

|

|

|

|

| From: Matt Ewing

|

|

|

|

|

|

|

| Date: 25-Jan-18 |

|

Looks like your getting the hang of it Ron. I hope to get back into selfbows next year.

|

|

| From: Matt Ewing

|

|

|

|

|

|

|

| Date: 25-Jan-18 |

|

Looks like your getting the hang of it Ron. I hope to get back into selfbows next year.

|

|

| From: Knifeguy

|

|

|

|

|

|

|

| Date: 25-Jan-18 |

|

Hope you and the wife get to feeling better soon. Take care old buddy! Lance.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 25-Jan-18 |

|

Ain't THAT the truth. Musclewood. You should see some of the staves of that stuff I have here. Looks awesome, and I always wanted to make a bow with a back like that, but now I'm afraid to try it :^)

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 29-Jan-18 |

|

I'm still up in the air about what glue to use to glue together my billets, I know it needs to be a slow drying glue so it will soak in to some extent.

Has anyone used Titebond III

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 29-Jan-18 |

|

I used tb3 on mine, but it has a laminated grip and that changes the game. If your splice is fit nicely I would use it for yours as well. You can always glue it up, then work it down a 1/2" or so and add lams. That will strengthen it all up nicely.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 29-Jan-18 |

|

I prefer to use glues with gap filling properties. I've used Smooth On EA-40 epoxy. It's available most anywhere bow making supplies are sold. Unibond 800 is another good one.

Some glues 'soak in' more than others. Titebond is one such glue. I wouldn't want to use it for a straight up selfbow splice, since I have what I think are better choices, but if I HAD to, I'd make sure the fit was perfect, then size all contact surfaces with the glue, let it sit and soak in until it was almost dry, then coat everything with glue again, assemble, and clamp with moderate pressure... but still probably wouldn't fully trust it :^)

What I really liked for this was Resorcinal, a very strong two part waterproof glue, but they quit making it.

|

|

| From: Kwikdraw

|

|

|

|

|

|

|

| Date: 29-Jan-18 |

|

Great lookin' splice Ron, I'm impressed for sure! And lookin' forward to the build. Looks like you are becoming a bowyer! Keep up the good work! Wyatt I'm gonna try a mesquite next, real wavy, twisty wood, but I like a challenge. We'll see, might just be a "wall hanger".

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 29-Jan-18 |

|

Thanks Pat. Now that you mention it, I did hear about that some time ago. I'll look into it. I still have some DAP Resorcinol unopened, but not sure it would still be good.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 29-Jan-18 |

|

Yep, I just checked it out. That looks like the same stuff. I'll be getting some.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 29-Jan-18 |

|

Pat, I have some aircraft epoxy that I bought from aircraft spruce, it dries in 24 hours extremely strong, I will have to check to see if that is what you are referring to.

Thanks

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 30-Jan-18 |

|

Patrick, I ordered the Cascophen from Aircraft Spruce today, Thank you.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

I have some ES6279 Aeropoxy with a shear strength of around 4000 PSI, I cut a set of practice billets made from spruce, I may glue them up to see how strong the glue joint is.

This epoxy is made for metal, wood and composite materials and it is the best epoxy I have ever seen, it will not peel off of wood after a long time, most epoxies will. Drying time is 24 hours.

Just to see how it works, will let you know in a couple of days

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

You guys are making this way too difficult :) . Ron, I would use what you have and not waste time on a test. Glue the sucker up and move along my friend! Marc St Louis uses TB3 almost exclusively. Splices, backings and anything else. I have used it in a lot of ways myself and have had ZERO glue failures.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 31-Jan-18 |

|

Thanks guys, I know I'm way over cautious, but it's on the way. I like experimenting also, i will try that epoxy on the practise staves just for the heck of it.

I'm working on the billets removing the shellac, I'm also keepinhg them in my drying box the staves measure 13.5% moisture. Want to dry them a little before I glue.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 07-Feb-18 |

|

I haven't forgot my HHB I had it in the drying box at 80 degrees for three days because the moisture content went up to 14%.

I wanted it dry enough to glue, well I guess I over did it, it's reading 5.2, I removed it and am checking periodically waiting for the 8% mark so the glue will adhere.

Sorry for the bumbling, I'm figuring all this stuff out, the Hickory took a little longer to dry. Cascophen requires a certain moisture content.

Will post when I progress

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 07-Feb-18 |

|

Take your time. We're not going anywhere :^)

|

|

|

|

| From: badger

|

|

|

|

|

|

|

| Date: 07-Feb-18 |

|

I have been using TB3 for years and well over thousand bows. I use it on ipe, osage, and any other wood we use for bows. Fit the surfaces right and use at least a 60 grit surface it won't fail, if it does it is operator error. Ipe is actually stronger of glued with the cheap yellow glue or tightbond 1 original.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 08-Feb-18 |

|

I glued up the HHb this morning and lined up the tips over the handle, didn't have to move much lined up pretty well.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 08-Feb-18 |

|

That resorcinol is amazing, I see why you guys use it, I believe as badger, titebond III will most likely work just fine, but this stuff you will not even have to think about a failure.

it really bonds to wood.

I mixed up way too much, I should have had my Osage cut and ready to be glued could have done both.

It's been about ten hours since the glue up and this stuff is cured. Tomorrow I will cut the bow to shape and continue on removing the shellac.

I will take photo's tomorrow, I didn't have my cell phone with me, this thing has a lot of backset, I hope not too much.

I plan also on a rounded belly like Dean Torges lists in his book.

This will be another step forward into an Osage.

Thanks for following, progress will pick up now.

|

|

| From: Dry Bones

|

|

|

|

|

|

|

| Date: 08-Feb-18 |

|

In for the ride. Waiting for more.

-Bones

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 18-Mar-18 |

|

Well, so much for jumping on the bow build, too many things got in the way, but am back on it.

I have the billets glued together, the tips aligned with the grip, and am trying to get the shellac off the back of the bow, I have tapered the limbs a little so it would start looking like a bow....Ha!Ha!

I have used several methods of removing the shellac, finally resorted to the heat gun to soften it and wipe it off now i will sand down the remaining bit to smooth the back out without getting into the second ring, which isn't far away, fine rings, have to be very careful here.

The dark areas is what it looked like before I started to remove the shellac.

I have a little propeller twist in the limbs, but will take care of that when I get the limbs ready to tiller.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 18-Mar-18 |

|

picture didn't come through, I will try again

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 18-Mar-18 |

|

That must be nice to bs working on that. I havent even gone back out for those two hhb trees yet, since the snow is litearally knee deep here and crust halfway down. Its like trying to hike in half set cement, you break through that midway crusty layer and get augered in by your ankles. Snowshoes could make it happen if i can get out before Thursday. But I doubt it, just too much going on.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 19-Mar-18 |

|

That dark brown stuff is what's left of the cambium. As with hickory, it doesn't HAVE to come off, but I'd try to get all I could. I'd scrape and sand the shellac off, but all of it doesn't have to come off either. Whatever you do, the most important thing is not violating the first growth ring.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 19-Mar-18 |

|

That wood right there looks a bit like oak to me. Quite a bit in fact. Can't wait to go collect those trees and turn them into staves, then selfbows. The snow is still 4$$ deep getting in there yet though. Fugidaboutit.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 19-Mar-18 |

|

Jeff, I did what you suggested and used denatured alcohol and I used 220 grit sand paper after that and what a difference, I didn't sand much, just to smooth the surface, I'm quitting now.

I like to talk out what I'm doing as to give info that may help and to let everyone interested in knowing what I am doing whether right or wrong.

Now I am going further into shaping the bow, I am going to make the lower limb shorter by 2" to try and get the bow to balance in the hand as per Dean Torges instructions. The specs. I'm shooting for are a 68" AMO 50lbs at 27.5" draw.

Jeff, gave me some measurements from one of his bows to help me get started, I really appreciated that Jeff, Thank you

I am going to make a rounded belly bow, not a flat bow like my last.

I have to leave now to see my cardiologist, as long as he can keep my ticker going I will be bow building.......Ha!Ha!

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 19-Mar-18 |

|

That's fine Ron. And that's why I sometimes answer the same questions here again that I've answered in emails and p.m.s. So others might benefit.

All the best at the cardio.

|

|

|

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 19-Mar-18 |

|

The cardiologist said I was going to live at least another week.......He is funnier than I am.......LOL! Everything is fine, I can continue shaving wood.

I just passed a point where something else should be done, but since meds are taking care of the problem I will continue, he also stated in three years we most likely will have to do an ablation in the heart, if I wait any longer the chance of blood clots will be too great past age 75.

Thank you gentlemen for your concern.

I spent all day with him and I didn't get anything done on the bow, tomorrow I will start drawing out the shape and narrowing up the billets, it is supposed to rain all day.

It was two billets, now that it is glued together isn't it considerd a stave????

|

|

| From: George Tsoukalas

|

|

|

|

|

|

|

| Date: 19-Mar-18 |

|

Yes, Ron...a stave from billets. Thank God for the good news. Jawge

|

|

| From: Knifeguy

|

|

|

|

|

|

|

| Date: 19-Mar-18 |

|

Glad to hear that you'll be around for awhile. We all need our stand up comic! Lance

|

|

| From: Stoner

|

|

|

|

|

|

|

| Date: 19-Mar-18 |

|

Ron, thanks for the build-a-long and glad to hear your health will take you through the build.

One question : Can someone please post or PM me on where to get the resorcinol glue? Thanks John

|

|

| From: Mountain Man

|

|

|

|

|

|

|

| Date: 20-Mar-18 |

|

The Key Ron ole pal is to tell them doctors you need to pay the bill in allotments Theyll give more time. ; )

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-Mar-18 |

|

That is a good idea Scott.

Yes Aircraft Spruce and that stuff is strong wow!

Here is a photo after I tackled the stave once more trying to remove the shellac this is where I am leaving it, I kind of like the looks.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 20-Mar-18 |

|

Twist up a string. She's ready! :^)

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 20-Mar-18 |

|

Can't wait to start on one of those. That's pretty wood... Its the dead of winter here yet though, and its the first day of spring. Can't get to the spot without snowshoes and freezing my tail end off. Was 4F here this morning. Crikey, will it ever end? Nice job on that glued stave Ron. Prayers for your good health also.

TK

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-Mar-18 |

|

Thanks Jeff, I have to narrow it down a bunch she is still too stiff to even move a limb with floor tillering.

It still is the original width I recieved it in, I just tapered the last 18 inches a little, now I will get my circle template and start marking the shape, it won't take long to whittle it down to those measurements, then I can start the tillering, my absolutely favorite part, I actually love all parts of the build especially with all this help which gives me the confidence to go on.

I know one thing, I need to sharpen up my cabinet scrapers this wood is tough. Ha!Ha!

Thanks Trapper, you will get your stave, just hang in there, I think this will make a better bow than my Hickory.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

Why does that concern you, Pat?

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

Ron, while you are at it, can we see a pic of your finished hickory bow for comparison? Would like to see how it turned out. Thanks! TK

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

True it does, but I believe he will have plenty left to keep it it solid. Especially if he chooses a bulbous handle, that keeps you around 1.375", 34.925 mm, for Pat :), wide at the bulbous portion.

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

I sent Ron the pattern to use on his bow. True, yeah, it might be an issue if the handle was very narrow and shallow. I use the same pattern, with a bulbous handle, and haven't had an issue in a bow, with many over 60 and some over 70 lbs.

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

Does it make a difference if you narrow it before or after making the splice? Is it better left wide in the handle? Should you use overlays? Thanks. Just trying to learn.>>>----> ken

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

I don't believe either is better than the other. Some guys splice full width and some don't. If either way is done correctly you wont have any issues.

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

Thanks Pearl >>>----> ken

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

Leaving it a little wider is a good idea to keep your options open, for alignment leeway if your billets are slightly misaligned, or you could use the room to layout around knots or other issues, and especially in character or snakey bows.

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

And, the width leaves the grip style options limitless.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 21-Mar-18 |

|

Thank you for your concerns and replies,

I mentioned that I was going to follow Dean Torges instructions on this bow just to see how it will function and he loves the bulbous grips which I believe I will like also.

I have a block of blood wood from Africa that is dense a wood as you will find plus super hard, I plan on surrounding the grip with that stuff and hope it will return the strength back to the bow that will be compromised when I narrow it down, but understanding torsion and shear as much as I have witnessed, I believe because of the square inches of the splice it would be fine if that was reduced as much as half, plus that resorcinol is some mighty tough stuff.

I even had the thought of installing dowels between the two billets, but it will break somewhere else, not the glue joint, I have run tests like this before in building airplanes and the glue joints are always stronger than the material you glued if done properly.

I am also using the blood wood in the tips.

Trapper, I will put them side by side tomorrow and shoot a photo, this one will be narrower because of the design and the toughness of the wood, also I am going to cook it as the experts suggested to temper the grain.

Thanks for the concern Pat

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-Mar-18 |

|

Trapper,

here are a few photo's I didn't realize I had placed the bow against a similar colored background.....Ha!Ha!

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-Mar-18 |

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-Mar-18 |

|

The side view above I had to string the bow, as you can see the HHB has a bit of reflex and the hickory has stringfollow.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-Mar-18 |

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 23-Mar-18 |

|

I have the width fairly close, now I will measure and cut to length and work on the nocks, thickness, crown and floor tillering.

Pictures later

Thank you everyone for participating, did I ever mention that I love doing this....LOL!!!!!!

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 11-May-18 |

|

Life got in the way of finishing this bow two months ago, but an getting a little time each week.

I am floor tillering the bow, i have the general width and the belly rounded as soon as I am satisfied on the tiller I will cut to length add the string nocks and start tillering on my station.

As soon as it is half way tillered I will toast the wood before continuing........Thank you Chris

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 11-May-18 |

|

Ron, when life gets in the way and I finally get a chance to work on a bow. It's totally therapeutic. Enjoy your bowyers time. Bless You All. Bjrogg

|

|

|

|

| From: Kwikdraw

|

|

|

|

|

|

|

| Date: 11-May-18 |

|

Looks great Ron, hope you can keep working on it! Lookin' forward to the finish! WYatt

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 11-May-18 |

|

Thank you everyone, stuff happens and you just deal with it. I have had a lot worse in my life, it just makes you a little more thankful for what you have.

Actually this time off has helped me calm down a little and help me see what I need to do to finish, i feel very confidant.

Thank you friends.

|

|

| From: duvall

|

|

|

|

|

|

|

| Date: 11-May-18 |

|

theres a trick I saw on youtube that you can use to get the rest of that cambium off. Pour boiling water over it and use a spoon to just scrape it off. That is unless you like the 'camo' look of it.

I have a couple HHB staves and I found 2 nice trees while turkey hunting I'm going to go get.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 11-May-18 |

|

RonG, thanks for posting those pics. I just saw this thread again, had forgotten about it when life got in the way (last post I made was the day before surgury, now 7 weeks ago...wow). Thats a nice looking coupla bows. Hoping your situations are under control and in Gods care too. Have fun with the hhb. I am about a week or two from cutting mine down. :)

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 13-May-18 |

|

Thanks Duvall I will keep that in mind.

Trapper glad to see you recovering, take it easy bro and don't over do.

|

|

| From: Bjrogg

|

|

|

|

|

|

|

| Date: 13-May-18 |

|

If you have access to a high pressure hot water power washer it works fantastic. Your back will be as clean and pristine as a growing season peeled off when the cambium slips. It's alright to leave some cambium on though and does look kinda cool. Just don't violate your ring. Bjrogg

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 13-May-18 |

|

I do have a 3000 pound pressure washer, that sucker will remove layers of wood in a heart beat, I like the cambium on the back it does look primitive. I will leave it as it is, thanks for the ideas.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-May-18 |

|

I got a little time to work on my ironwood bow.

I came across these little knots on the belly, I think you call them pin knots,

they weren't noticeable when I was shaping the limbs, as I got down to where I could floor tiller is when I noticed them. Not a lot maybe three, and on one limb only so far.

On the back of the bow you can just make them out.

Since I am leaving some of the cadmium on the back I won't have to mess with them, but what about the belly, should I just sand them down with the rest of the bow limb, I plan on tempering the limbs when I get a little further along.

So far the limbs are 1.25 wide at the fades and .750 thick.

gradual taper to .625 wide and .625 thick at the tips with a rounded belly.

the length from tip to tip is 70 inches right now, may decide to shorten that length to 68"

It floor tillers nicely, nice even limb arcs from limb to limb the tips are stiff for about 10 inches and it's a little stiff in the fades.

If I put this bow on my tillering station it probably would be near 80 pounds @ 10" draw. pretty stiff yet, I won't string it until I take some more off.

I hate working on something then coming back to it, I like to stay with it so I won't forget where I left off.

This is coming along good I think unless I messed up something on those knots.

Please more help.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-May-18 |

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-May-18 |

|

And this one showing the three knots

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 20-May-18 |

|

I miss marked the center one, the third one is to the right just out of the photo, shown in previous photo.

|

|

| From: BowAholic

|

|

|

|

|

|

|

| Date: 20-May-18 |

|

looking good Ron...when you use the scraper on those knots it might get a little washboardy on you...just hit them lightly with a sanding block or rasp... looking forward to seeing your progress.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 20-May-18 |

|

RonG, thanks, coming along good. Nice looking start to a bow you have going there. It is close to time for me to go get my tree. Gotts haul a step ladder about 1/4 mile, and hopegully can get the tree with a bow saw, not the chainsaw. That might be a futile effort.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

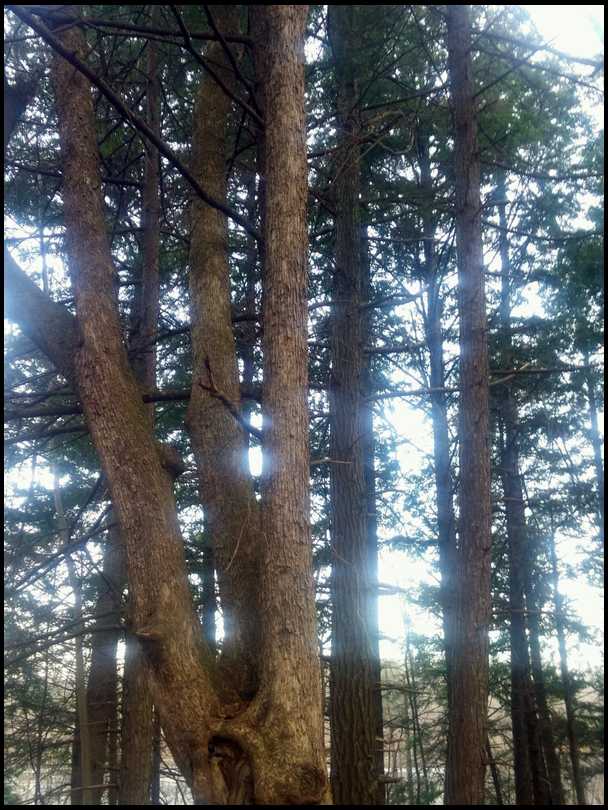

I need to cut it above this fork, which is about face high.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

Its the one on the right coming out of the fork, nice and long and straight. I think a bow saw will do it. I've gotta have it.. :^)

|

|

| From: PEARL DRUMS

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

These knots are on almost every HHB bow you will make. Just keep them as far off the edge as you can and continue along. They wont cause issues most often.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

Here is the other one, half beaver chewed, but started fresh last fall so I think its all right. Hoping it is on the ground by now.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

Its another straight one, but not as perfect as the other one (hoping they both are once the bark is off).

|

|

| From: tonto59

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

Well Done! Sure would like to see a build along. To see better how splices are done. I'm guessing you could make a nice take down bow from billets as well?

|

|

| From: Kwikdraw

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

Lookin' good Ron, really like the wood! Turning out well!

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

Looking good Ron. Don't worry about those knots yet, they might disappear as you remove more wood in thickness on your way to your target weight. The most concerning one is the one closer to the edge. If it's still there later and you want to fill it, you can fill it with an epoxy/sawdust mixture.

Trapper, those are some nice looking trees. You best be careful cutting on a ladder. I cut one small, standing dead Osage with a little bow saw and it took ME down. It was dead a long time and was like petrified wood, standing on top of a bank, and I really struggled with that cheap bow saw until I got mad... and when it was almost cut through, I threw that junk saw and yanked and pulled and pushed until the tree snapped off, I fell down the bank, and the tree fell on top of me. Good thing it was a just a little 5" tree. It wasn't a graceful fall, and I bet it would have been funny to see :^)

I've cut a few decent sized Osage trees with those old big crosscut saws, you know the kind folks paint stuff on and hang up on a wall? Properly sharpened, they'll go right through an Osage or Ironwood tree.

Cutting bow wood can be a real adventure, and half the fun.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

Thanks Chris and Bob. Those knots under close inspection are not what average knots look like, except for the little brown hard center they look like part of the grain, when I get tillering is when I will inspect them closer, they are not large maybe I can cut that one out that is on the edge and tiller, will have to make that decision early so I won't get a thirty pound bow, looking for at least a 55lb.

Thanks everyone.

Trapper, bring some lubricant for that bow saw and I hope you are a young man, those beavers didn't quit on those trees because they got distracted, probably wore their teeth down......Ha!Ha!

I have to admit it does produce nice curls with a sharp cabinet scraper.

It is continuing to rain for the last five days so I have bow time, Yahoooo!!

Will post better pictures soon and I have to splice my two Osage bullets together so I will post a build on that.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 21-May-18 |

|

I think maybe I'll take the chain saw along too, and maybe just be able to reach it standing, without the stepladder. That sounds like a not-fun adventure Jeff. I also thought about the ladder being not a great idea. I say that because a friend of my wife's was cutting a broken limb in his yard from that snowstorm in March, from a ladder, and the limb kicked up and took him out, and messed him up real bad. Spent 9 days in the hospital ICU with a 6 inch cut on his head, 5 broken ribs, broken scapula, punctured lung and lacerated spleen. These ironwood trees are no thing to play with, they are heavy and pretty good sized - 7 inches anyway. I'll try the bow saw, but I think it would be one heckuva cut. They have a tendency to get pinched off easily when the weight goes on the blade. NO I'm not a young man. :)

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-May-18 |

|

Trapper, I was just letting you know maybe you should bring an extra blade.

It's an unusual wood dried, it's tough but scrapes fair, saws pretty good with a coarse sharp blade, but laughs at sandpaper, the wood is tough.

good luck on your journey Maybe the live wood cuts easier.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-May-18 |

|

Did a bunch more scraping sanding an filing, cut small string nocks for tillering, will start that in the next couple days, when I get it to the point of stringing the bow then I will heat temper the wood as suggested by Pearl Drums. I have left it at 68" from nock to nock until I can get an idea of what I have as far as weight.

I will add to the handle, I was intrigued by Pearl Drums handle he put on his last build, I may try that, after I get it tillered A little more, and I am going to add overlays on the bow tips.

A couple of photos, not real good.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-May-18 |

|

pardon my little hand plane had to have something to hold it down.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-May-18 |

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-May-18 |

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-May-18 |

|

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 22-May-18 |

|

I forgot to mention that the limbs look thick, but it floor tillers nicely, can't wait to put it in the tillering station to see what I have.

I am not rushing this one like I did my hickory, there will be a lot of careful exercising on the tillering station.

Thank you everyone for your interest and support, I am striving to make this one much better than my hickory.

So far it looks like it may be a 68" AMO 55 to 60 lbs. oil finish, string BCY-X 12 strand double bundle nylon served doubled. now if i just don't screw it up ....Ha!Ha!

|

|

| From: Jeff Durnell

|

|

|

|

|

|

|

| Date: 23-May-18 |

|

You won't. But even if something happens beyond your control, more bow staves grow every day.

|

|

| From: TrapperKayak

|

|

|

|

|

|

|

| Date: 23-May-18 |

|

Looking good Ron. Thanks for the advice, I bet a couple blades will be necessary if I do the bow saw. Or start out with a brand new one and see how long it lasts... :) Going for it this weekend. Could make for an interesting Memorial Day weekend memory, good one that is. Will dedicate the finished bow to all those who have served.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 23-May-18 |

|

Thanks Jeff, I know, but these three (Hickory, HHB, Osage) that I received from a special person have a special meaning, they are more than wood cut from a tree, I am doing my best and being careful to produce a usable product, plus I am learning a lot.

I really appreciate the kindness that I have received from everyone.

Trapper, Maybe Jeff or Pearl or Jawge can give you a better idea of how the wood cuts green, I never have cut one here in Florida, all we have is pine, cypress, sycamore and oak.

That is a great idea Trapper, cut it on Memorial day and dedicate to the troops.

I wanted to mention that we got a bottle of wine with a cork, not a screw on cap....Ha!Ha!...so I will make my arrow rest from that......I may name the bow after the bottle of wine...Just kidding.

I rushed my hickory bow, it came out at 50lbs, but is now down to around 43 @ 28", it is not gotten any weaker, still shoots smooth and quiet and that leather dye on that grain made the prettiest bow. I may try 5/16ths arrow shafts to get it to shoot flat, I am using Douglas Fir 11/32 and they are a bit heavy, they drop quickly past 15 yards, they shoot point on at 25 yards.

I will massage this next one carefully to help prevent that.

Thank you all for your interest and help.

|

|

| From: RonG

|

|

|

|

|

|

|

| Date: 18-Jul-18 |

|

Well, I know you thought I disappeared from the leatherwall selfbow site, not on your life!

I sold all my R/C airplanes as of yesterday and in the process of cleaning and converting my model building shed into a wood working shop. I have to remove the deck and smooth out 52 yards of dirt to bring the level up to where the water doesn't stand after these heavy rains. I'm glad I have a backhoe and front end loader, I'm too old to do it any other way...LOL! Then I will bring my tablesaw, bandsaw, planer and vacuum into the newly modified space and wire it up for 220 volts, again using the front end loader. Then I will get back to building selfbows, just letting everyone know I am still here and fully interested, the iron wood bow doesn't lack too much more. anxious to start the Osage. and will definitely buy some Yew as this is probably my favorite wood so far anyway.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|