| From: ny yankee

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

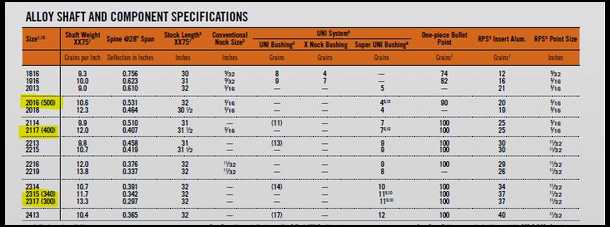

Haow can you tell wall thickness on these shafts? Are they the same as the corresponding XX75's (2117 .400 etc) or are they different alloy? Are there any adapters to be able to use old style nocks on them?

|

|

| From: Catsailor

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

I bought adapters at 3rivers for mine because I standardized on Bohning Classic nocks. The gamegetters are marked with both designations. 400 also are marked 2117. 500 are 2016 and so forth.

|

|

| From: Catsailor

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

You might want to consider the Tribute shafts. The have swaged ends for the nocks you want to use.

|

|

| From: Kevin Lawler

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

21/64 in outside diameter and .017 in wall thickness. They used to make nock adapters in plastic and aluminum. There might be some old stock around.

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

Now, you know for sure that Easton didn't go and tool up anything new for these, right?

Tributes - not swaged, but ground down to a taper for glue-ons, if that's your preference; I'm pretty sure these are NOT the same alloy as the Camo Hunters and GGIIs, but if you're experimenting, $3/shaft is kinda hard to beat.

On the other hand, if you know what you need, the Camo Hunters are only a buck more... and the Legacies are PURTY!

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

They just took their regular shafts and put the deflection (rounded off) on the shaft. 500 are 2016. 400 are 2117 and so on. 340...2315, and 300 ...2317.

|

|

| From: ronnickel

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

Wall thickness = the second 2 numbers. 17 = 17/1000".

I shoot only Easton Aluminum shafts. 1816,1916 & 2016.

I like the Tributes, but swaged end + weak or old super glue can result in a dry fire. It happened to me 2x. They separated upon release.They were only a few months old.

I feel more confident with the press in nocks. (Gamegetters & Camo Hunter)

You can get alloy uni nocks @ 3 Rivers to glue in, if you already have swaged shafts and just cut them off.

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

I don't think you can grind down a hollow tube to a taper. Pretty sure they are swaged. Maybe they have something new though who knows? The last two numbers are the wall thickness.>>-->Ken

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

Well, you're the machinist! I may not be using the terms correctly... I thought the swaged ends were formed using a more demanding process that didn't remove any metal, but just formed it into a taper..

The Easton site says these (Tributes) are a "precision ground nock swage" - not sure if that's the same process used on the Legacies....

FWIW, I've never had issues with these...

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

You are right,no metal removed. We swaged in a lathe. The tool is pushed into the spinning shaft at the correct angle to push/form the end closed. Maybe Easton does a finish grind but the formed finish can be burnished very precise?? The only disadvantage to those shafts is you can't turn the nock for fine tuning.Once you figure out your preference that is not necessary any way.>>>----> Ken

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

Pretty sure Easton knows how they do it. Anyway, swaged nocks were used for many decades and dry fires from bad glue were, and are few and far between. I use fletching cement on my glue on nocks and never had one come off during the shot and I have shot a lot of arrows over fifty-couple years. I don't use super glue for any application in archery.

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

Well, I do use it to fill stress cracks because it does work for that.

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 16-Nov-17 |

|

George, certainly Easton knows how they do it. No harm in discussing it. I love swaged nocks they have worked for ever. Back in the day there were not a zillion components for both ends of the shafts.Simpler times. Any plastic/model glue works fine. Like you I have never had one come off that I didn't bust with another arrow.You are missing out on something good though. A bottle of good super glue with the needle spout does an excellent job of fletching. No excess glue on the shaft,quick,clean, and in 30 seconds you can rotate to the next feather. If you ever tried it you would never go back.Take care,>>>----> Ken

|

|

| From: DanaC

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

Fletched 6 with Gorilla's version of super glue. Not quite worth the hassle. Going back to Platinum.

I like the 'black' super glue - tire glue - for inserts, but it is as messy as I am clumsy!

|

|

| From: George D. Stout

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

2 Bears, Ken....I used it a long time ago and got a whiff of that stuff in my oversized snoot, and had to run outside. Man that was some acrid stuff. Anyway, I'm too damn sloppy to use it. I get it on my hands, and the table, etc., and it's heck to get off. Alas, I'm just a deplorable old curmudgeon who keeps resisting change. I have finally accepted that the world is round. Well, kinda round.

|

|

| From: Dan In MI

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

You guys should try this new internet thing. You can look up manufacturer specs easily..... ;-)

From the Gamegetter page on Easton's website.

Pre-installed Super Nocks (installed)

• RPS inserts included

• 7075-T9 alloy

• Straightness: ± .003

https://eastonhunting.com/target/gamegetter/

Watch flea bay for glue in nock tapers.

BTW - swaging is done with compression in a die. Spin forming on a lathe makes a similar end but not quite a strong. The spinning causes heat that can weaken the shaft.

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

George I loved your honest answer. As a bullheaded Ole 76 year old I hear where you are coming from. I would almost bet though that you used the little tubes or at least the tiny bottle. That is the very reason I love it. The large bottle tiny spout works in my arthritic, clumsy, hands. It dispenses tiny drops to be spread with the tip. no muss no fuss, no glue on hands and none squishing out around the base of the quills.One thing I will say---You and I get er done. Take care brother, >>>----> Ken

|

|

| From: 2 bears

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

Dan In Mi you are correct swaging is also done with die's. I forgot that because we used lathes so much more. Not sure which way Easton does it though because a die usually leaves a small opening at the top. It also takes a lot of pressure to do on thin walled shafts especially if not using the heat generating spinning along with the die. Good contribution. >>>----> Ken

|

|

| From: Mpdh

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

Broken push in nocks can be pulled out with either a crochet hook, or a drill bit that is just bigger than the hole. Just twist the bit so it grabs the soft plastic and pull. The nocks fit tight enough, that they usually don’t go very far down the arrow shaft.

MP

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 17-Nov-17 |

|

“Broken push in nocks can be pulled out with either a crochet hook, or a drill bit that is just bigger than the hole. “

Take a 3” piece of 1” dowel, and put a fairly long, self-tapping dry-wall or deck screw through the middle. Like pulling a cork out of a wine bottle...

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|