| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

So I've had the itch lately... I'm traveling to Korea this summer(and miss some school, yay!) and I need a takedown bow to pack there. Both sides of the family live in relatively remote areas, and one has acres of open fields and forest behind the.house and farm. Now, my problem is that all of the bows I have are one piece. Selfbows, longbows, and recurves, but no TDs. Well, my Olympic setups, but I'm not gonna go stumping with a 4lb chunk of aluminum in hand. So, I'll have to make a riser. This works out quite nicely because I have a set of 30# ILF recurve limbs for my oly bow, which work out to about 35# on a 17" riser. Note that this build is going to be mostly in real time, so this might take a while. This riser is going to be solid red oak, ugly as hell hardware, and a basic finish- but that's okay. This is meant to be a pure shooter, a bow I can toss into a bag and not worry about getting the mirror finish dinged up on the rough dirt roads or in the field.

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

FUN. ILF Self bow :)

Note...Limb pocket angles are CRUCIAL. I have a 17" Tradtech Galaxy that doesn't increase the draw weight. I move the same limbs between it and a 25" Hoyt. Then I have another cheap chinese magnesium riser from eBay that increases the draw weight as expected.

I want to make an Osage ILF Riser now...

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

So here's the wood for the riser. It's just a 1"x2"x6' red oak board cut into lengths to fit my pattern for the riser. The board was originally bought for the purpose of making a self bow, because of the straight grain, but I decided to make a riser just because I made a longbow from it's twin I found at the same time. The cost of the beard is something like $8, not at all expensive. The total cost of this riser, excluding tools and labor, will be under $30(hopefully, if all goes to plan, which it won't.)

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

Here's the riser block glued up. Note that there is no phenolic or fiberglass, or and fancy footing. That's because I am a broke sophomore just tryin' to get through high school without lots of tools or a car.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

I don't foresee any problems. This will be a neat little project.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

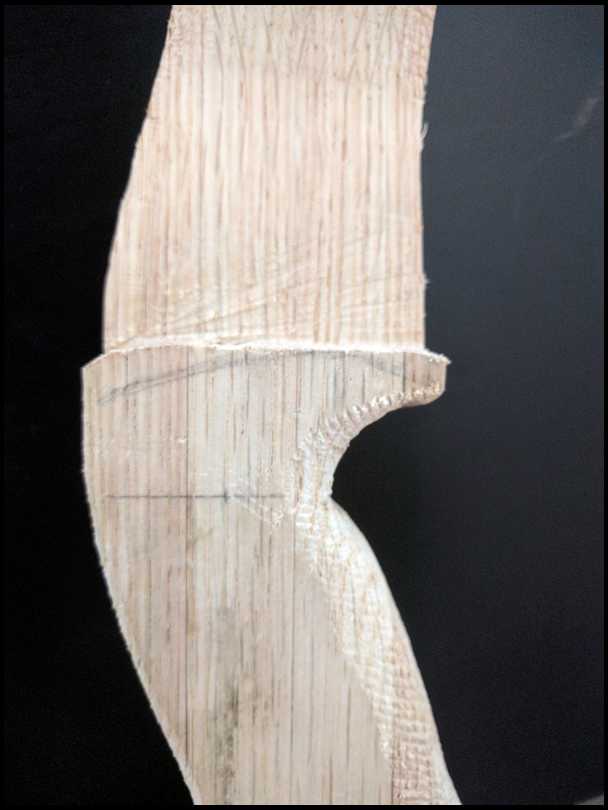

Ok, this is where things go into real time. I removed the excess glue with a chisel, and the gorilla wood glue that I use peels off fairly easily. I like gorilla wood glue because it has a more natural color than titebonds. I freehanded the limb pad angles with a circular saw. I do NOT recommend this, because it will not be accurate at all, but with time and care the angle can be sanded and planed to fit. I then used a hand saw and chisel to remove the bulk of the material. Whew! I'm sore all over right now. After a little bit of filing, this is what the contours look like:

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

fdp, you were wrong. Problem number one: I only posted the last picture. Here ya go:

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

This is what the limb pads looked like after the circular saw. I used an orbital sander to get it down near the lines, and a hand plane set real fine to flatten out the angles.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

That's all for today, folks. Don't expect any updates for a while, as I have school to contend with for five days before I can get back to any serious work with the riser.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

I don't see the problem.

Try using 2 sided tape to stick a piece of 80 grit sandpaper to a piece of 1x4. That way you can old the riser in your hand, and apply pressure to sand the limb pockets against the 1x4.

Also, before you go after it with a chisel, take a fine toothed saw and make shallow cuts ACROSS the surface you will be chiseling, that way, if the chisel does get away, the grain can't run any further than the cross cut.

And, when chiseling on a surface like that, turn the chisel over. Bevel down nort up. In fact, with a good sharp chisel you can almost use it like plain that way. It will be MUCH easier to control the depth of the cut, and won't be nearly as likely to get away.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 16-Apr-17 |

|

Fdp, I meant that I only posted one picture in that post, when I had meant to post three. Your tips about the chisel are absolutely correct, but the big chisel I was using is more for whaling away at big chunks of wood to reduce mass quickly and efficiently. When I'm making joints or tenon's and mortises with my other, finer chisels, I do exactly as you suggested. Thanks.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 21-Apr-17 |

|

Hey guys, I managed to get some work done yesterday after school. I got the profile of the riser more refined, but most importantly, I got the sight window cut in. You can see the two saw marks that I hacked out wood in between with a heavy chisel.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 21-Apr-17 |

|

I need help... :p So I'm trying to crown the shelf, but without a router or a belt sander it's taking a good while. Any ideas?

|

|

| From: Longcruise

|

|

|

|

|

|

|

| Date: 21-Apr-17 |

|

A really rough rasp. Push it ONLY into the work. A farrier's rasp will work but it's very aggressive.

|

|

|

|

| From: Msturm

|

|

|

|

|

|

|

| Date: 21-Apr-17 |

|

yep that is a 5 minute job with a farrier's rasp

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Farier's rasp, Sureform rasp or large Surefomr plane, least expensive will be to go pick you up a 4 in hand rasp. You can get it in several sizes, and there are 4 different levels of aggressiveness to the bite.

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Do you have a set of cabinet scrapers? When you get them sharpened correctly, they are good for radius work on the shelf. And they are cheap!

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

And be careful with a rasp...you can get the contour you want, but when you smooth out the rasp marks, you lose a good bit of wood (when you are working on small precision areas).

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Thanks, guys. I took your advice and took to the shelf with a rasp and file. It went by pretty fast.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

I spent a lot of time with a rasp in hand shaping the riser more.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

After a lot more sanding, here's where it's at:

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Now all that's left is figuring out how to drill the bolt holes with a hand drill, putting in hardware, and finishing. What stain do you guys think will work? I'm thinking a natural or golden oak, something not too overpowering.

|

|

| From: Bob Rowlands

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Nicely done Styks. And thanks for the buildalong.

|

|

| From: bodork

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

That's impressive. Especially considering the tools you have to work with. Not to mention your young age. Refreshing to see young people use something other than a cell phone. Good job!

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Are you planning to use threaded insert/bushings for the limb adjustment bolts? I'd be interested to know how to get good tights clean threads cut into the wood for that. And then recess the limb plates?

Do you have a template for the limb pad angles?

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

JustSomeDude, it's coming. I'm not using threaded inserts, but I will try to tap the wood.

|

|

| From: HALFCAWKT

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Sir, I believe tapping the wood is flirting with disaster.

Finish? It may be cheap and easy to use Truoil. It is what they used to finish the old walnut rifle stock from the years before synthetic stocks. They were beautiful. You just rub it in in fine coats with your fingers or a rag. You can get it at Walmart or many places Gun cleaning accessories are sold. Easy clean up, spills are not the end of the world.

|

|

| From: Babysaph

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

That is awesome

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

+1 on TruOil

Tapped wood WITH threaded inserts is how my TradTech Galaxy is made.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Basically, I'm going to be tapping the wood to give the bolt a little more to hold on to, but not all. You'll see-it'll be ugly as hell.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

And I'll say it again. This one of THE neatest projects that has come along here in a while.

Absolutely outstanding work.

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 22-Apr-17 |

|

Styk

TradTech taps all the way through. The insert threads in flush. You tighten limb bolts in and then set screw from the other side holds your adjustment. It works extremely well so far. I have shot and adjusted the crap out of this riser.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 23-Apr-17 |

|

I can't wait to see that riser after you apply some finish to it. That's going to be a good looking riser.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 23-Apr-17 |

|

Here is the list of hardware I will be using: 2x 3/8" hex bolts 4x steel washers 2x 3/8" hex nuts

I chose a golden pecan stain just because dark stains tend to look cheap sometimes. I will also be making my own tap, but first I have to find a friend with a drill press :p

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 23-Apr-17 |

|

JustSomeDude, the limb pad angles are approx. 18", just little more actually. I just used the trig I am learning in class(finally, a useful application for precal!) and found that if I measured 4" in, and 1.25" up, that would give me an 18 point something angle. Not too worried about exact angle, because most ILF risers, for trade anyways, have different angles.

|

|

| From: Schleprock

|

|

|

|

|

|

|

| Date: 23-Apr-17 |

|

What did you use for the pattern?

|

|

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 24-Apr-17 |

|

I may end up taking another trip to Lowe's to pick up a couple 3" bolts, instead of 2.5", as well as some t nuts. I'll countersink the belly of the riser to fit the t nuts.

|

|

| From: Schleprock

|

|

|

|

|

|

|

| Date: 24-Apr-17 |

|

You said "18 point something angle" is there a range within which you were aiming? I would imagine there's numbers you wouldn't want to be over or under?

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 24-Apr-17 |

|

I tried to stay over 17 but under 20, because too steep an angle loses speed once the limb tips are behind the back of the riser and the massive preload you get with shallow limb angles can cause stacking and bad manners.

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 24-Apr-17 |

|

I am worried that you are rolling the dice on your pocket angles. Theres a lot of engineering going on there. It might take some experimentation to find the right limbs.

My 17" Tradtech Galaxy is an oddball in that limbs are almost what they were rated to be on a 25" riser. I have another 17" riser that raises the weight just about half as you would expect.

|

|

| From: Tzioxphon

|

|

|

|

|

|

|

| Date: 24-Apr-17 |

|

Yes, way too much preload. Looks like 12 plus pounds on limbs marked for 25.

|

|

| From: reddogge

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Why don't you ask Sam Dunham (Hiram). He has lots of experience with limb pad angles from doing warfs.

|

|

| From: Deno

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Sam IS Tzioxphon

Deno

|

|

| From: J. Julian

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Tzioxphon is Sam Dunham

|

|

| From: J. Julian

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Sorry deno beat me to it

|

|

| From: Kwikdraw

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Great job Styks, I'm duly impressed, haven't seen many HS anythings accomplish such a tricky project! And keep up the good school work! Wyatt

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Yeah, I was kind of modelling of of the dryad risers that I really want. Those are rated to 8+ pounds. Keep in mind, though, that the limb bolts will open up a lot more. The limb pad angles are not the same as the actual angle of the limbs. If it turns out to be a problem, well, I guess I'll have to make my own limbs!

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Go ahead with it. Keep in mind when making risers (or designing bows) that the further ahead of the pivot point of the grip the limb tips are the more preload there will be. As the limb tips move closer to the pivot point of the grip, the preload will decrease.

That's one of the reasons that many of the more popular longer bows current and past, have the limb tips forming a line that runs through the pivot point of the grip when unstrung. That's for bows in the 60" and up range.

As bows get shorter, the limb tips move further back, (reflex) to keep the bow from having too much preload when strung.

You can easily work out angles using graph paper or cardboard riser teplates, along with cardboard or 1/4" wood patterns of the limb profile/length that you are considering.

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Actually I should have said "deflex" rather than "reflex above. Sorry.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Yeah, if I'm being 100% honest with myself I just made a shallow angle because deep inside, I know I want to make some ilf longbow limbs ;)

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

18° doesn't seem to be too unusual for an ilf riser, I've found lots of old threads where 18° was used for ilf risers. Do you know what angle most 17" risers use?

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Angle doesn't tell the whole story. The riser length plays a big part

|

|

|

|

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Overall bow length and the archers draw length have to be considered in the limb pad angle as well. Longer limbs will move the limb tips back, shorter limbs will move the limb tips forward.

Personally for a longbow I would work on a riser with 10 or less degrees of angle, but that's just me.

You could easily use this riser and just shim the limb pad to get the ideal angle for you.

|

|

| From: Orion

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Styks; Just eyeballing it, your 18 degrees looks fine to me.

|

|

| From: tecum-tha

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

1.) Good you did not cut this riser past center. That is a stupid thing to do in an all wood riser. 2.) The corner in your sight window between the vertical and horizontal part is pretty sharp. This should be rounded out nicely. 3.) Red oak would have been my the last choice of wood due to the short wood fibers and the grainy texture. 4.) I would not put any heavy limbs on this riser as it is using not the strongest parts of the wood in the axis of resistance.

Other than that, nice work. P.S. The Koreans have very good traditional bows and I would rather shoot one of those than an ILF rig....and you will visit the source :-))

|

|

| From: aromakr

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Dongyu: Might I suggest something with your next project. In one of your post you mentioned you sanded the limb pads then brought them to their final with a hand plane. NEVER SAND BEFORE YOU USE A CUTTING TOOL LIKE A PLANE, sanding will leave sanding grit in the surface of the wood and dull your plane real fast. Otherwise great project especially using only hand tools. Hope it stays together. I would have used a different wood and glue, but that's how you learn!!!

Bob

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Aromaker, thanks for the tip. Tecum-tha, I'm going to the Homeland, but I've shot Korean trad in New Hampshire before I moved to Texas. It's really relaxing actually.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

If anybody wants to send me better wood, or power tools I can cut phenolics with, or maybe just a dryad or Morrison, I'm all for it... ;)

|

|

| From: jk

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Check Southwest Archery in Arizona for $500 phenolic recurves.

|

|

| From: Schleprock

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

So what's a good wood?

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

Bubinga, Osage, actionwood, padauk, goncalo alves, rosewood, canarywood, checked, wenge, walnut, ipe, any dense and hard wood really.

|

|

| From: Schleprock

|

|

|

|

|

|

|

| Date: 25-Apr-17 |

|

I get that. I was wondering if someone who suggested another wood would actually suggest another wood.

|

|

| From: Schleprock

|

|

|

|

|

|

|

| Date: 26-Apr-17 |

|

I've been looking around on the internet and Rockler looks like a good place to get wood.

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 26-Apr-17 |

|

Check this place out: http://www.keimlumber.com/exoticwoods I was in Ohio and wandered in there randomly. SURPRISE

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 26-Apr-17 |

|

When you're buying lumber you are far better off being able to look at it.

If you have a Woodcraft store in your area, there is a strong possibility that you can get what you want/need there, and be able to handle it and look it over before you buy it.

I just bought some very nice Purpleheart and Maple at the Woodcraft in Austin, and they had a very good selection of more exotic material should I have wanted it.

I will only buy lumber from I can't select myself from a VERY small list of suppliers.

|

|

| From: HALFCAWKT

|

|

|

|

|

|

|

| Date: 30-Apr-17 |

|

Have you finished the project yet?

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 30-Apr-17 |

|

Sorry this is taking so long guys, I have a lot of things going on right now. AP testing, teachers trying to get grades in, family, friends, etc. I was hoping to get some things done this weekend but some things came up. I'll get the update to you guys as soon as possible.

|

|

| From: hawkeye in PA

|

|

|

|

|

|

|

| Date: 30-Apr-17 |

|

I have enjoyed reading and seeing your project, along with your sense of humor.

|

|

| From: 1/2miledrag

|

|

|

|

|

|

|

| Date: 30-Apr-17 |

|

Styks- you have captured both my interest and respect with this project. Hats off to you already. Can't wait to see the end result. Best thread I've read in a long time. Outstanding and thanks.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 02-May-17 |

|

Hey guys, I'm going to try and stop by Lowe's this week to pick up some more tools I need for this project. They include longer (3") hex bolts, T nuts, and a tap. In the future, I might mess with making my own threaded inserts, but that might be biting off more than I can chew!

|

|

| From: JustSomeDude

|

|

|

|

|

|

|

| Date: 02-May-17 |

|

You can likely find threaded inserts at the hardware store. It will increase the life expectancy of your riser (and maybe your face too!)

|

|

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 03-May-17 |

|

Impressive stuff! I was making my own bows at your age, but they involved nothing more than the fiberglass rod from a bike safety flag, some mason line, duct tape, a hacksaw and a file... LOL

I'm going to have to show this thread to my 14-year-old, but I think it's going to have to wait 'til we've finished reconditioning the bass guitar he's been working on...

Keep those updates coming!

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 03-May-17 |

|

GF: if you have tools, your fourteen year old could probably turn out a bow in a week instead of the month it's taking me... Ah, to be young again! XD

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 03-May-17 |

|

Got some tools - just no drill press.

It's the precision angles that throw me off...

|

|

| From: fdp

|

|

|

|

|

|

|

| Date: 03-May-17 |

|

GF, those angles aren't nearly as precision as you think.

Most of them come from the school of "this looks about right".

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 04-May-17 |

|

Funny you say that, fdp... Bad news, guys. Looks like another one for the fire. It was completely stupid, I just rushed and drilled some terrible holes for the limb bolts. This one's not surviving... Sorry for the letdown guys. Thanks for the kind words on the way.

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 04-May-17 |

|

I'm not done though, already planning for the next one, maybe gonna go a little less cheap and find a drill press somewhere as well. The only thing is, now I don't have a bow I can take with me to Korea I don't know how I'm going to get through school tomorrow with this weighing on my mind...

|

|

| From: GF

|

|

|

|

|

|

|

| Date: 04-May-17 |

|

Did you see that $20 job at Lancaster? Might save your trip!

Of course, it's not ILF, and maybe that means you'd have to buy limbs as well...

Still a pretty square deal, but not quite as cost-effective as you had in mind!

|

|

| From: bustedarrow

|

|

|

|

|

|

|

| Date: 04-May-17 |

|

Would you be able to clean out the drilled holes and epoxy in some hardwood plugs and do over?

|

|

| From: Styksnstryngs

|

|

|

|

|

|

|

| Date: 05-May-17 |

|

Busted arrow, that would involve then redrilling through part of the plug, which would significantly weaken an already borderline riser.

|

|

If you have already registered, please sign in now

For new registrations Click Here

|

|

|

|